- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

- From the Blog

How I lost my machine tool

- By Ken Hurwitz

Tips from a lender on what to do if your machine tool is getting repossessed.

How Much Does a 5-Axis Machine Tool Cost?

- Canadian Metalworking

- Metalworking

Think past the initial price tag and consider long-term ROI and profitability! With various available working ranges, software packages, automation pairings, and more, Okuma 5-Axis machines are worth the investment.

Is your Technology Ready to Support the Business you Want to Be?

- Canadian Metalworking

- Metalworking

Quality CMMs And Vision Measuring Systems Are A Driving Factor EV Manufacturing

- Canadian Metalworking

- Measurement

TC52 Enables Rifle Manufacturer To Produce Precision Barrels

- Canadian Metalworking

- Measurement

- Industry News

- Sustainability Analyzer Tool helps users measure and reduce carbon footprint

- HGG Profiling Equipment BV names Western Canada area sales manager

- Mitutoyo updates its end-user portal

- Portable 3D scanners offer adjustable scanning distance, advanced volumetric accuracy

- GF Machining Solutions names managing director and head of market region North and Central Americas

- Aluminum MIG welding wire upgraded with a proprietary and patented surface treatment technology

- 3-axis servo-driven mill combines professional-grade capabilities, easy-to-use compact versatility

Achieving success with mechanized plasma cutting

- By Jorge Santana

- Apr 22, 2024

Identifying the hallmarks of a modern CNC

- By Joe Thompson

- Apr 19, 2024

- Latest from Our Publications

A newer way to turn

- Apr 10, 2024

Portable system becomes hot tech in heat treatment

- Apr 17, 2024

Class is in session for college connections

- Apr 12, 2024

Fractal Fabrication gets back to basics

- Apr 3, 2024

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Health & Safety

- Event

The CME will host its 2024 Health and Safety Symposium on May 29 from 8 am to 2 pm at the Mississauga Convention Centre.

Gas mixer delivers precise mixture adjustments quickly for laser welding

- Apr 25, 2024

- Welding

- Product Release

Witt’s MEM+ gas mixer offers a choice of seven interfaces to integrate into existing laser welding machines using protective or process gases.

Hypertherm Associates partners with Rapyuta Robotics

- Apr 24, 2024

- Automation and Software

- News Release

Rapyuta Robotics’ Pick Assist AMRs allow Hypertherm Associates to automate warehousing and empower its associates in a sustainable manner.

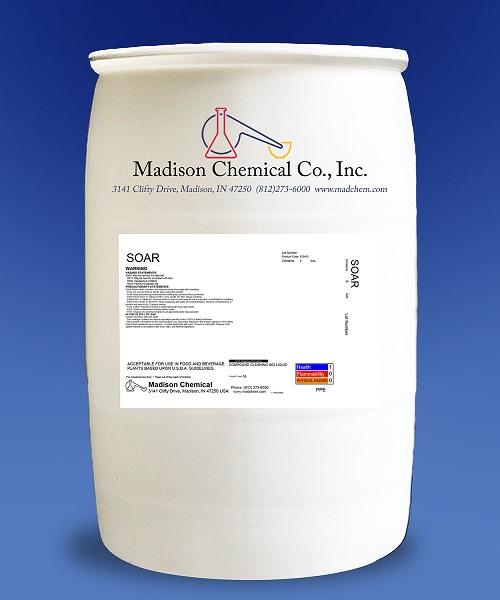

Liquid acidic cleaner removes rust and stains without harsh fumes

- Apr 24, 2024

- Health & Safety

- Product Release

Madison Chemical introduces SOAR HF, a liquid acidic cleaner designed to penetrate and remove rust, oxides, calcium carbonate, and other types of deposits.

Compact weld camera monitors TIG, plasma processes

- Apr 24, 2024

- Measurement

- Product Release

Xiris has introduced the XVC 310 Lipstick Weld Camera for GTAW and plasma processes in confined spaces, such as narrow gap and orbital applications.

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

- Apr 23, 2024

- Cutting Tools

- News Release

Sandvik Coromant hosted a Girls Take Over Tech open house to inspire and educate women and girls about exciting career opportunities in manufacturing.

Gema welcomes controller

- Apr 23, 2024

- Metal Finishing

- News Release

Indianapolis-based powder coating equipment manufacturer Gema USA Inc. has added Alicia Czyszczon as controller.

Sandvik acquires Buffalo Tungsten

- Apr 23, 2024

- Cutting Tools

- News Release

To secure the supply of such a tungsten for both Sandvik and its customers, Sandvik acquired Buffalo Tungsten Inc. (BTI) in December 2023.

Brushless copper tubing cutter adjusts to ODs up to 2-1/8 in.

- Apr 23, 2024

- Fabricating

- Product Release

Milwaukee M12 brushless 1-1/4- to 2-in. cutter automatically adjusts diameter to cut Type K, L, and M copper pipes from 1-3/8 to 2-1/8 in. OD.

CTMA launches another round of Career-Ready program

- Apr 22, 2024

- Metalworking

- News Release

Eligible employers can receive up to $15,000 to assist with hiring and training.

Welding system features four advanced MIG/MAG WeldModes

- Apr 22, 2024

- Welding

- Product Release

ESAB has introduced its Warrior Edge 500 DX multi-process power source featuring four advanced MIG/MAG WeldModes as well as an Advanced Pulse WeldMode.

Association of Advancing Automation (A3) celebrates 50 year anniversary

- Apr 22, 2024

- Automation and Software

- News Release

The company will celebrate their golden anniversary in Chicago on May 6 to 9 at Automate 2024.

Collet chuck provides accuracy in small diameter cutting

- Apr 19, 2024

- Metalworking

- Product Release

Lyndex-Nikken MMC Mini-Mini collet chuck features a slim and compact body for precision machining with small diameter tools, up to 0.500 in.

CWB Group launches full-cycle assessment and training program

- Apr 19, 2024

- Welding

- News Release

The CWB Group has officially announced its Welder Competency Assessment and Skills Training (WCAST) program. This program, which will provide education and training opportunities to newcomers and other individuals pursuing a career in the welding and joining industry, will initially be...

Tooling for spot facing and counterboring is completely customizable

- Apr 18, 2024

- Cutting Tools

- Product Release

Heule has introduced SOLO L tooling for spot facing and counterboring projects over 25 mm. Front and back counterbores up to 1.95 x bore diameter can be produced in bores ranging from 25.0 to 45.0mm in diameter. The tooling features a simple design which functions without an anti-rotation...

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Aluminum MIG welding wire upgraded with a proprietary and patented surface treatment technology

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

Automating additive manufacturing

Achieving success with mechanized plasma cutting

CTMA launches another round of Career-Ready program

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada

FABTECH Canada

- June 11 - 13, 2024

- Toronto, ON Canada

Zoller Open House & Technology Days 2024

- June 12 - 13, 2024

- Ann Arbor, MI