- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Milling Software

- March 23, 2015

- Product Release

- Automation and Software

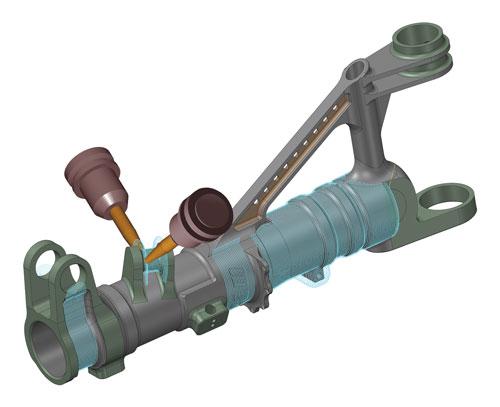

Mastercam X8 Mill offers expanded machining flexibility and an increased emphasis on speed and automation with new dynamic motion, 2-D machining, and multiaxis features.

Dynamic motion technology is a new approach to creating toolpaths using a proprietary set of rules to analyze tool engagement and material removal while constantly changing the cut motion based on what the tool will encounter at the machine. The results include shorter cycle times, less wear and breakage of tools, and less wear on machines, the company states.

Multiaxis roughing has been added for this version. It allows for pocketing toolpaths to be created easier and enables rough out pockets with a curved floor surface. Safety zone improvements make defining and editing the safety zone easier as well, says the developer. Tool inspection has been added to many multiaxis toolpaths, including Blade Expert and Port Expert.

Two-dimensional high-speed toolpaths (HST) now support multicore processing on toolpaths with multiple machining regions, and the 2-D HST Dynamic Mill feature has added first-pass feed reduction and first-pass offset to the Cut Parameters page, allowing for safer motion when the tool is entering material from the outside. It also expands the machining region to ensure the tool does not engage a lot of material on the very first pass because of an unknown exact block size.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

CTMA launches another round of Career-Ready program

Collet chuck provides accuracy in small diameter cutting

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI