- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

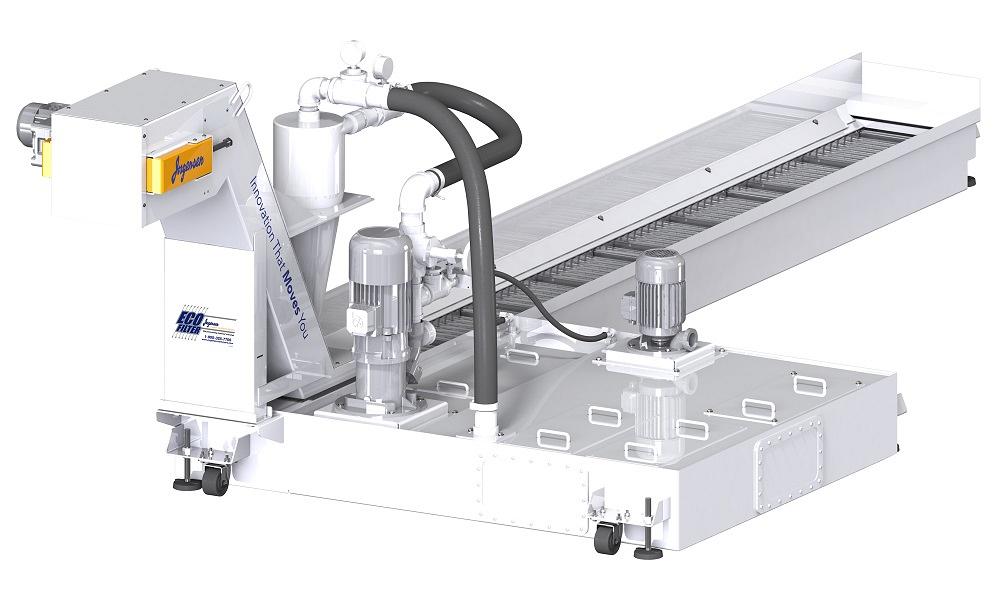

Jorgensen's PermaClean high-pressure coolant system enables faster, cleaner cutting

- November 3, 2022

- Product Release

- Management

Jorgensen Conveyor and Filtration Solutions has introduced three new systems to reduce labour and improve performance throughout the entire machining process.

The new PermaClean filtration system eliminates sludge buildup by adding optional agitation to the coolant collection tank. Eductor nozzles keep coolant in motion, suspending chip particulates and preventing them from settling. Collection tanks equipped with PermaClean combined with cyclonic filtration are virtually maintenance free and significantly reduce the labour required for frequent tank cleaning.

It incorporates into the company’s multi-step filtration system that includes the EcoFilter conveyor and filter cell, additional filtration options, and fine filtration for high-pressure applications. It also adapts as an option to improve the performance of any Jorgensen filtration system on the market.

To further reduce coolant tank maintenance, the company offers Will-fill, a new metalworking fluid optimizer. This system combines automatic volume measurement and metalworking fluid analysis with faultless filling, permanent conditioning, and timely reporting to provide worry-free coolant care.

FlexForce is the company’s new high-pressure coolant system that outperforms flood systems. Available in 500- and 1,000-PSI options, this system breaks through the heat-generated vapour barrier created at the cutting tool and workpiece that can cause surface deformities and damage tooling. It penetrates this barrier and gets coolant directly to the cutting zone, improving lubrication and heat dissipation, speeds and feeds, and chip control. Plus, it increases coolant and tool life and provides improved surface finishes, the company states.

Jorgensen Conveyor and Filtration Solutions | www.jorgensenconveyors.com

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI