- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Software developed for moldmakers

- February 27, 2024

- Product Release

- Automation and Software

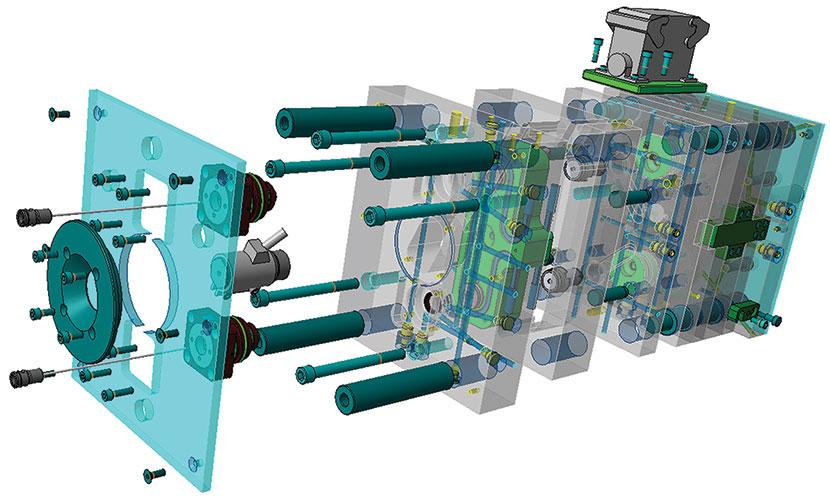

Hexagon’s Manufacturing Intelligence division has released HxGN Mould & Die, a suite of dedicated CAD/CAM, engineering, and automation software tools designed for mold, die, and tool manufacturers to increase efficiency, reduce costs, and produce high-quality parts.

The suite was developed to empower moldmakers and designers to achieve operational excellence in the design and manufacturing of plastic injection molds, progressive dies, forming dies, and similar tools.

Capabilities of the suite include CAD/CAE (computer aided design and engineering) for plastic injection mold design, CAD/CAE for progressive die design, CAD for manufacturing preparation, CAM for CNC machine tool programming, process simulation and G-code verification and optimization, shop floor production intelligence, and automation and collaboration powered by Nexus, the company’s digital reality platform.

For plastic injection mold manufacturers, the suite provides tools for design and engineering, flow simulation, reverse engineering, automated electrode design, and CNC machining. Its reverse-engineering tools allow moldmakers to create solid models from scanned data—a crucial capability for mold repair and redesign, and for creating solid models for manufacturing when CAD files are not available.

The suite also provides plastic flow analysis tools that help shop floor teams produce cost-effective and reliable molds.

The creation of intricate or difficult-to-machine injection mold features is further simplified with the automated design and simulation of EDM electrodes and their associated holders.

For progressive die manufacturers, the software offers a connected workflow with tools for design and engineering, simulation, and production. It enables the step-by-step unfolding of surface and solid models, which gives designers more control over the development of each forming stage. Flexible strip layout capabilities and the ability to simulate the performance of the strip at any stage in the design process make it easy to quickly analyze the results of design changes. The software also helps manufacturers predict springback.

Prior to machining, CNC programs can be simulated and verified using NCSIMUL, the suite’s G-code simulation software, which incorporates the entire machining environment to generate an effective digital twin of the machinery, part, and processes.

Hexagon Manufacturing Intelligence | www.hexagonmi.com

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI