- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Al-Mg-Si coating protects against steel corrosion in ships, coastal facilities

- March 30, 2022

- News Release

- Metal Finishing

Scientists develop new anti-corrosion coating to increase the economic life and durability of steel machinery in an environmentally friendly manner. Korea Maritime & Ocean University

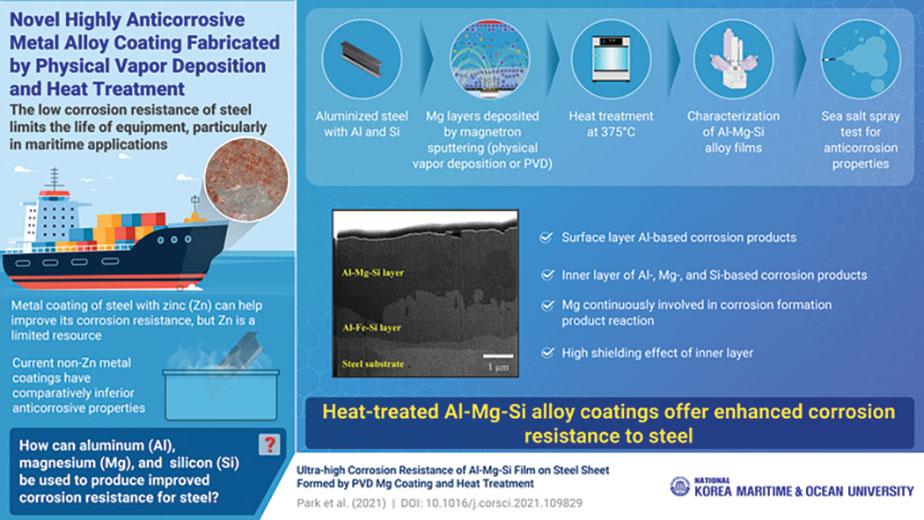

Scientists have developed a new aluminum-magnesium-silicon anti-corrosion coating designed to increase the economic life and durability of steel machinery in marine environments.

One of the most common methods of improving the corrosion resistance of steel is coating it with other metals such as aluminum (Al). But the use of Al in marine applications is limited because it reacts with chloride ions in the sea water, leading to corrosion. The addition of other elements, such as magnesium (Mg) and silicon (Si), to form an alloyed coating is a promising way around this problem. But Mg cannot be easily deposited as a coating using the conventional method of dipping the steel into a hot bath of metal salts.

In the study “Ultra-high corrosion resistance of Al-Mg-Si film on steel sheet formed by PVD Mg coating and heat treatment,” published in Corrosion Science, scientists have developed a new protocol for Al-Mg-Si coating of steel.

“When I served in the navy, I was constantly looking at rusting machinery. Since then, I have become fully engaged in research on how to produce better anti-corrosive steels,” said professor Myeong-Hoon Lee of the Korea National Maritime and Ocean University, who led the research.

In this study, researchers took aluminized steel (with Al and Si) and then plated it with Mg using physical vapour deposition. This was followed by heating the coating to 375 degrees C. They then characterized the coating film and performed corrosion testing in the form of a salt spray test. They found that the corrosion products were formed in two layers: a surface layer made of primarily Al-based corrosion products, and an inner corrosion layer made of Al-, Mg-, and Si-based products. Moreover, the inner layer of corrosion products produced a shielding effect, which further improved the anti-corrosion properties.

“Our research reveals how a highly corrosion-resistant steel can be produced using a simple change in the surface treatment protocol,” said Lee.

The study’s authors are Gi-Dong Park, Ji Hoon Yang, Kyung-Hwang Lee, Hyo-Jin Kim, Seung-Hyo Lee, Jun Kang, Yong-Sup Yun, and Myeong-Hoon Lee.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI