Founder/CEO

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Create a maintenance champion in your shop

A good champion manages assets, inventory, time, and maintenance activities

- By Bryan Christiansen

- August 2, 2022

A maintenance champion works with third-party service providers or internal IT teams to develop facility-specific computerized maintenance management systems (CMMS).

Shop floors have a blend of production assets working in unison to achieve specific production goals. They have different maintenance requirements and demand timely preventive and predictive measures to avert downtime and costly damages.

Regardless of your maintenance strategy, you need to appoint competent maintenance personnel to coordinate maintenance activities.

Appointing a maintenance champion to coordinate operations within the maintenance department is a great idea. They collaborate with managers from other departments and vendors, ensuring timely communication for streamlined production planning.

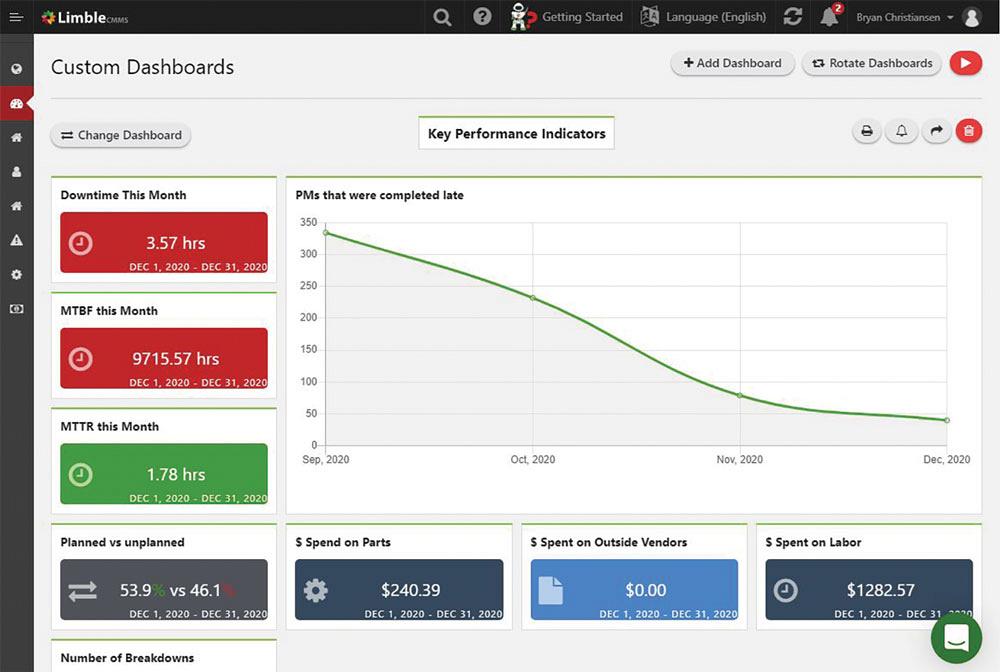

A maintenance champion should have a deep understanding of routine production activities and factory maintenance. Technical expertise allows them to identify troubled production assets, offer advice on appropriate intervention measures, and track their performance using available technological tools. Companies typically appoint a long-serving maintenance expert as the shop’s maintenance champion. This individual needs to know how to perform equipment audits, handle work orders, schedule maintenance tasks, and formulate and track necessary performance indicators.

The maintenance champion requires more than technical expertise of shop floor operations. This individual is a captain who steers the department and the company towards maintenance excellence. As such, they require good interpersonal and leadership skills. They should possess impeccable people management skills and be capable of communicating technical details with ease.

The champion also needs to be flexible, a good problem solver, and curious to explore innovative and cost-effective maintenance strategies. These strategies should include the following:

1. Standardize Maintenance Programs and Coordinate Staff Training

The maintenance champion oversees change management in the factory as they seek to standardize maintenance operations in the company. They are the frontrunners when the company embraces digital transformations in maintenance. The maintenance champion facilitates the standardization of maintenance work by:

- Working closely with third-party service providers or internal IT teams to develop facility-specific computerized maintenance management systems (CMMS).

- Formulating relevant equipment maintenance plans.

- Developing and updating standard operating procedures (SOPs) to reflect changes in the number of shop-floor assets and production technologies.

- Formulating management policies for maintenance, repair, and operations (MRO) inventory.

Factory floor experiences transform over time. Companies phase out old equipment and technology in favour of improving the efficiency and productivity of assets. Digital transformation comes with new challenges, tools, and opportunities for maintenance teams.

It is the maintenance champion that coordinates training for technicians. They explain how digital systems work and ways technicians can exploit them to enhance routine operations. Training builds confidence, making technicians comfortable to use technological solutions. Maintenance champions also facilitate safety training for maintenance personnel.

2. Act as a Continuous Improvement Agent

The maintenance champion is an all-around individual who can perform quick machine fixes and conduct detailed failure-mode and root-cause analysis. They monitor the performances of factory floor equipment using production and maintenance records and available digital tools. From the data collected, maintenance champions estimate the reliability of each production asset. They also evaluate the cost-effectiveness and the quality of existing maintenance programs.

Champions conduct regular facility audits to identify production assets with frequent failures. Because they manage plenty of maintenance data, these individuals provide recommendations to senior management on the viability of condition monitoring and predictive maintenance for critical shop floor assets. They also devise robust preventive maintenance plans to avert the postponement of maintenance activities that may jeopardize asset performance.

As a change agent, maintenance champions go beyond identifying, justifying, and implementing asset reliability programs. They implement quality assurance procedures for spare parts and tools sourced from vendors. They also evaluate prospective vendors to ensure the company purchases high-quality parts at affordable prices.

The maintenance champion evaluates skill gaps among shop floor employees and establishes relevant training plans to ensure everyone on the team is competent. They interpret maintenance data on behalf of technicians. Champions guide technicians to perform autonomous fault identification and analysis.

3. Identify and Implement Innovative Projects to Streamline Maintenance Activities

The maintenance champion is responsible for introducing and sustaining innovative maintenance strategies on the shop floor. They research the latest trends in equipment maintenance, leveraging practical experiences and digital resources to examine the options that are the best fit for the company. The evaluation takes into consideration potential benefits against the required investment.

The maintenance champion manages maintenance data from all corners of the workshop floor. They leverage maintenance data to create impactful asset maintenance procedures and innovatively eliminate maintenance bottlenecks.

For instance, they can identify routine activities that will yield impressive results if automated. They will, however, have to validate the claim and demonstrate that the proposed technology is sustainable. Aside from that, they spearhead the implementation and optimization of new technology.

4. Optimize Inventory Management and Streamline Vendor Engagement

The safety champion plays a pivotal role in inventory and vendor engagement. Champions source quality spare parts and tools and negotiate the best deals for the company. They work with individuals in the procurement department to ensure maintenance supplies are available at the points of need.

Timely deliveries are vital for averting maintenance delays. Optimized inventory management ensures the company is ready for dynamic changes in maintenance schedules.

They also develop policies for inventory management to rid the company of the burden of obsolete spares and low-quality parts. Additionally, they collaborate with original equipment manufacturers to draft framework contracts. These contracts guarantee that companies receive requisite after-sales support from the manufacturers. It also ensures they have access to hard-to-find replacement parts.

The champion is instrumental in driving change and providing leadership to maintenance teams when implementing technological tools. Maintenance champions are highly skilled individuals that can coordinate activities among individuals, departments, and external stakeholders.

The maintenance champion is a valuable resource on the shop floor. They constantly focus on improving processes and employee skills. Having a captain to guide the maintenance department is an effective way to enhance the performance of assets and the technical team as a whole.

Bryan Christiansen is the founder/CEO of Limble CMMS, 3290 W. Mayflower Ave., Lehi, Utah 84043, 801-851-1218, www.limblecmms.com.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free SubscriptionAbout the Author

- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI