Associate Editor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Turbulence Ahead

With COVID-19 grounding many flights, Canada needs a strategy to kick-start its aerospace industry

- By Lindsay Luminoso

- July 30, 2020

- Article

- Metalworking

Prior to COVID-19, there were some headwinds for the Canadian aerospace industry. Globally the industry was growing at a 5 per cent level but especially on the manufacturing side, Canada wasn’t keeping pace. This presented both a challenge and an opportunity.

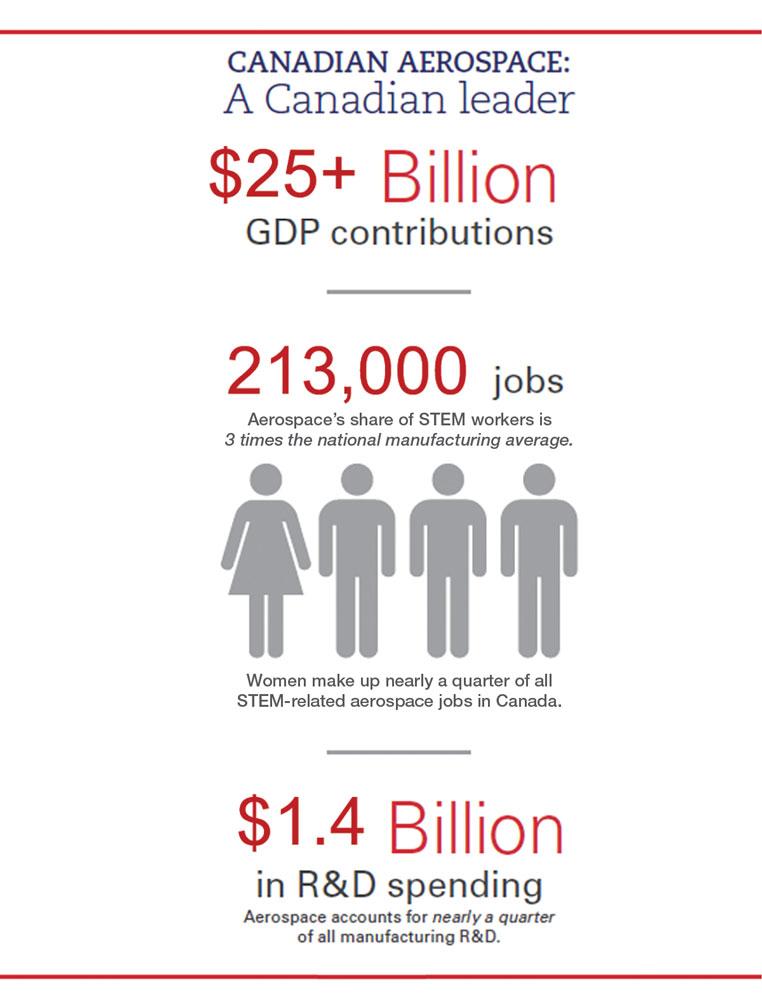

Today Canada’s aerospace industry is the fifth largest in the world and ranks in the top three in multiple production categories: civil flight simulators, turboprop and helicopter engines, and business jets and regional aircraft. In 2019 the industry contributed $25 billion in annual GDP.

But with the global COVID-19 pandemic, the Canadian aerospace industry has been one of the hardest-hit sectors. Most countries have implemented travel advisories or put travel bans in place to restrict the spread of the virus. Flights have either been cancelled with planes grounded or, in many cases, are operating with fewer passengers, which has led many aviation companies to cancel existing aircraft orders.

For Canada to continue as a global leader and competitive player in aerospace manufacturing, significant support and collaboration are needed from all levels of government, associations, private and public sectors, as well as the education sector.

"As an association, we’ve really focused on member engagement and ensuring provincial and federal announcements are given to the members in a timely manner," said Mike Mueller, vice-president, operations and communications at Aerospace Industries Association of Canada (AIAC)—Pacific. "It’s been really helpful to have that interface between the members and then also the decision-makers in governance so that they really get a sense of where we are at as an industry and some of the challenges that we’re facing."

Prior to the pandemic, AIAC created a Vision 2025 report titled "Charting a new course: Canada as a global aerospace champion," which outlined a number of priorities to help the industry better position itself moving forward.

"We saw there were some headwinds for the Canadian industry," said Mueller. "Most noticeably, at a global scale, the industry was growing at a 5 per cent pre-COVID level. However, especially on the manufacturing side, Canada wasn’t keeping pace. As an industry, we came together and went across the country, consulting with players all across the sector to create this report."

This collaboration resulted in AIAC identifying six priorities to help the sector remain competitive:

- Support the skilled workforce to help large labour market challenges.

- Ensure small and medium-sized businesses can thrive and grow.

- Use innovation to capture new opportunities, including carbon-neutral flight and unmanned vehicles.

- Invest to maintain Transport Canada’s internationally recognized status for aircraft certification and regulation.

- Maximize Canada’s leadership at the forefront of space.

- Maximize defence procurement and government partnerships to drive new industrial growth.

"Today these prescriptions ring even more true," said Mueller. "And, really, as we look towards coming out of the pandemic and into recovery, a lot of these same themes are going to be very important for that success."

Current Challenges

It is clear that the pandemic has either slowed or stalled production in many industries. And that is particularly true for aerospace manufacturing. The AIAC reached out to its member businesses to gauge the status of the sector.

After surveying its membership, the AIAC determined that there is quite a bit of impact at the local level, and many small and medium-sized businesses are facing many challenges. Interim results show that overall aerospace companies in Canada anticipate a 40 per cent decrease in revenue this year.

One of AIAC’s biggest recommendations to the federal government is to get the airlines moving again. At the end of the day, the airlines are the industry’s end user, especially with respect to civil aerospace manufacturing.

Further, 95 per cent of companies are running at partial capacity or shut down, and 93 per cent of firms anticipate running at partial capacity for more than two months. Based on the survey, a vast majority of companies have already laid off some employees, and 76 per cent anticipate layoffs in the next six months.

"It paints a pretty devastating picture for the industry," said Mueller. "Manufacturing as a whole in Canada, for the most part, doesn’t show quite the same struggle. However, once you break out aerospace, it’s clear to see that we are one of the most impacted sectors. It’s quite dramatic. I would say that aerospace is one of the top three most impacted sectors. And it’s just more of a reason why we need the government to partner with us on a strategy for the sector moving forward. Our aerospace market, with 80 per cent of our product exported, can play a pretty significant role in helping the country come out of the crisis."

Recovery Efforts

The AIAC has been looking at how best to move the industry forward and actively help it recover. Mueller said that they are constantly asking, What do we need to come out of this?

"It’s about how can we support the supply chain going forward," said Mueller. "This is especially true for the small shops and businesses. We need to help implement changes to deal with some of these new realities with COVID-19 and how we can make them more efficient and better positioned to come out of the pandemic."

One of the biggest recommendations, specific to the government, is to get the airlines moving again. At the end of the day, the airlines are the industry’s end user, especially with respect to civil aerospace manufacturing.

A number of programs are currently in place to help industries across the country, such as the federal wage subsidy that was recently extended to August to further help those affected by the pandemic. Mueller noted that this was especially helpful for shops and businesses in this sector because of the longer lead times that often go with it. He anticipated that many of these shops will feel the effects of the pandemic well into the summer and leading into the end of fall. However, safeguards are in place, like the federal wage subsidy, to help offset the hit that the industry is facing.

One of the interesting things that Mueller has noted about the pandemic is that many of the decisions have been driven at the local and provincial level. Different provinces had different essential services designations and deemed different sectors essential. This made it somewhat more of a challenge to navigate and get the industry from all areas of the country on the same footing. One of the biggest successes was getting aerospace, MRO activities, manufacturing, and defence identified as an essential service both in the public safety lists that were put out and also the Transport Canada list.

"And so now our attention is really turning towards health guidelines and personal protective equipment," said Mueller. "We just want to try and get some consistency across the provinces with respect to those things. And again, the health and safety of the workers is the utmost priority."

Things change week by week during the pandemic, and restrictions today may not necessarily be in place tomorrow, or a second wave may wipe out all the progress that was made. So it’s challenging to see where the aerospace industry will be in the next few years, but for now, Mueller said that this is a great opportunity to work with the government and key players to transition the sector and better position it against international competitors.

Continued Success

"We also need to start thinking about the best ways to move forward," said Mueller. "We think taking a green technology perspective and exploring supply chain innovation will open up opportunities. So how do we ensure manufacturing companies are better positioned to come out of this? We need to expedite public procurement, in particular defence and space projects, and then really work with the government on a long-term strategy for the sector."

In Canada, aerospace is unique given the fact that most Canadian firms don’t compete against each other, they compete collectively against other countries. And to continue with long-term success, the sector needs to sustain its innovative approach and compete globally while attracting investment to Canada. Having focused government support that identifies the priorities for Canada to remain a leader in the global aerospace industry is necessary moving forward.

Green technology, carbon-neutral flight, and autonomous vehicles are all emerging trends in the industry that Canadian companies have invested in in recent years, even prior to COVID-19. For example, Harbour Air in Vancouver had one of the first commercial electric aircraft flights in the world.

"We have so many companies in Canada doing amazing and innovative things," said Mueller. "We have, and continue to have, world-leading companies. We just need to continue pushing the boundaries and supporting this innovative approach.

"Other countries in the world have invested heavily, even pre-COVID-19, in their aerospace sector because they see the jobs, innovation, long-term productivity, and GDP gains that the industry can bring. A lot of other industries aren’t as globally competitive as aerospace. Our country, with 35 million people, has the fifth-largest aerospace sector in the world because of decisions the government has made. We need them to continue to partner with us. This is true even more so with COVID-19 to ensure that we come out of this and not only sustain what we have, but move towards a position of strength."

Associate Editor Lindsay Luminoso can be reached at lluminoso@canadianmetalworking.com.

AIAC, www.aiac.ca

About the Author

Lindsay Luminoso

1154 Warden Avenue

Toronto, M1R 0A1 Canada

Lindsay Luminoso, associate editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. She worked as an associate editor/web editor, at Canadian Metalworking from 2014-2016 and was most recently an associate editor at Design Engineering.

Luminoso has a bachelor of arts from Carleton University, a bachelor of education from Ottawa University, and a graduate certificate in book, magazine, and digital publishing from Centennial College.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI