- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Multitasking on multispindle machines

The experts explain the benefits of a multispindle machine for small-part manufacturing

- November 28, 2022

- Article

- Metalworking

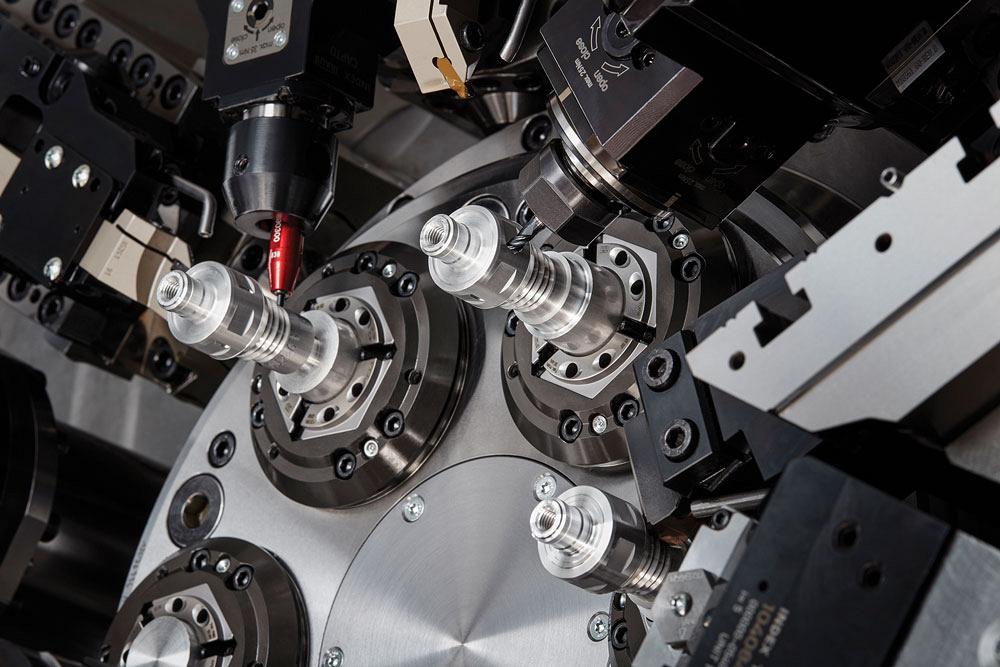

The Index MS32-6, a six-spindle automatic lathe, includes 12 cross slides, all of which can be configured for grooving and drilling, to handle complex components. The machine also can be configured to enable a range of machining processes, including off-centre drilling, threading, contouring, hobbing, and polygonal turning. Index

While mutltitasking most often refers to machines that perform both turning and milling, multispindle machines take this a step further by providing these processes on six spindles within a single machine. Tyler Economan, inside sales manager; and Ross Kenyon, applications manager, at Index, Noblesville, Ind., explain the benefits of working with a multispindle machine for small-part manufacturing.

Check out our November cover story on multitasking for small-part manufacturing.

Canadian Metalworking: What do shops need to consider when working on a multispindle machine?

Kenyon: There are so many benefits, but one of the advantages is that these machines tend to take up less floor space; they have a smaller footprint than other stand-alone machines. They require fewer operators than a machining cell and offer better traceability. It’s also important to note that parts are coming off these machines quicker than traditional machines, so you have to measure the parts quickly. You have to make sure you have a good inventory of tools and the necessary bar stock or material to complete the jobs.

CM: Which questions should shops be ask when determining if a multispindle machine makes sense for them?

Economan: We like to talk to our customers or potential customers about the parts they are interested in making on a machine like this. Sometimes that's existing parts, and sometimes it's new parts that they are hoping to take on. What does the part look like? How large is the part from a diameter and length standpoint? Does it fit on a particular machine? Is the geometry complex enough that it needs a specific number of tools? Is there a need for making parts better and faster? And if so, how many of those parts do you have to produce? That really helps us choose the machine type.

Kenyon: It’s also important to ask if the shop is running out of room on the floor. Will adding more machines make the shop floor crowded or will they even all fit? Do you have enough personnel to handle more machines? If you don't have space, then it's the right time to start considering a multispindle machine.

CM: How does a multispindle machine function as a multitasking machine?

Kenyon: Multispindle machines have either six or eight main spindles, one or two of which can be synchronous spindles for backworking. Each spindle can be served by two slides, and most slides can be equipped for live tooling so you can perform turning, polygonal turning, on- and off-centre drilling, contour milling, hobbing, and more. You’re completing the operations in parallel rather than sequential order. The synchronous spindles allow it to machine the backside of the part. The part can be picked up with a chuck or a collet system. We also have a reduced clamping force option, so for thin parts or parts that have tight tolerances, this makes sense.

Economan: When it comes to the synchronized spindles, the machine has the ability to clamp on the OD or the ID to provide the most flexibility so that whatever makes the most sense for the part geometry and quality, it can do.

CM: How can manufacturers transition from traditional machining methods to the multispindle machine?

Economan: Roughly 70 per cent of parts that are made on a Swiss machine or sliding headstock machine could potentially be made on a CNC multispindle machine. Just because the part is small, that doesn’t mean that it needs to be made on a Swiss machine. The transition is all about knowing how many tools are required for the job and determining if the multispindle machine can accommodate that. In many cases, parts can be made four to six times faster on a multispindle than a sliding headstock machine.

Some shops that are working with more cellular-style manufacturing can transition to multispindle. And while this was common in years past, we are seeing a lot of shops that are working with a machine that has a main and a counter spindle, whether it be a sliding headstock machine, Swiss machine, a two- or three-turret, or turn-mill machine, where the parts produced on it don’t require so many tools, switching over to a multispindle machine.

We’ve seen examples of where a shop is making complex medical parts in 10 to 12 minutes on Swiss-style machines and now are able to make those parts in around two minutes on a CNC multispindle. So, that's a huge gain in productivity.

Kenyon: A multispindle machine can be used for unattended machining, but it has to be the right fit. Non-ferrous applications are normally better for this. In these cases, the machine can be loaded up at the end of the day with material and produce parts overnight.

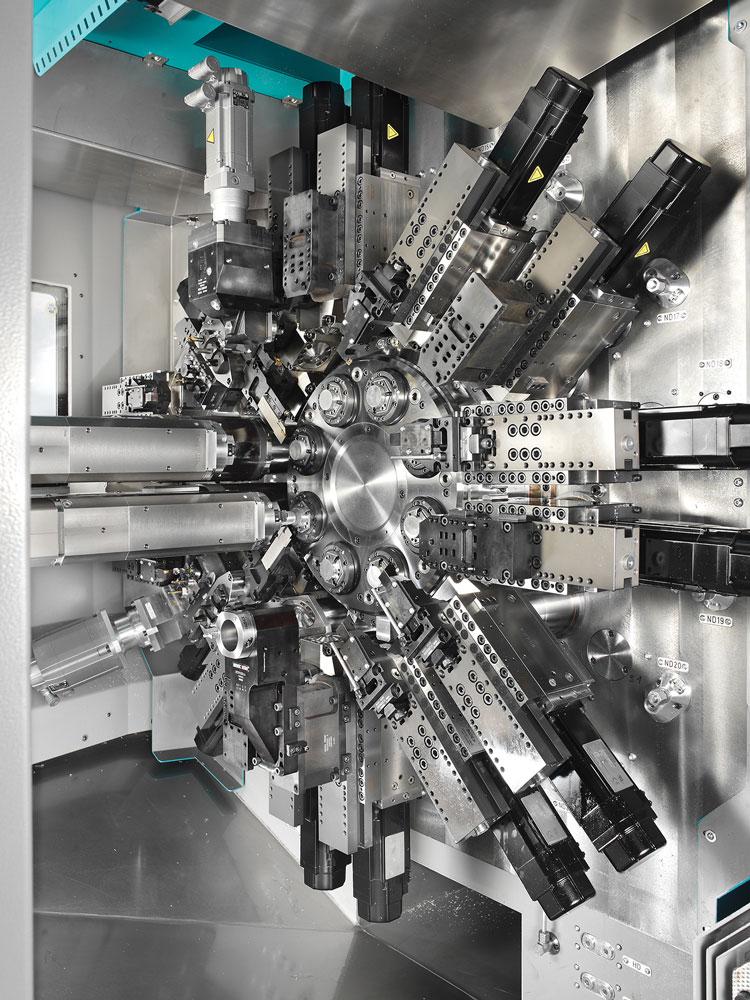

The Index MS40C-8 multispindle automatic lathe includes a compact spindle drum with eight fluid-cooled motorized spindles with synchronized technology and can completely machine complex parts in one operation. Index

CM: Are there any misconceptions with working with a multispindle machine?

Kenyon: One misconception is that an Index multispindle is difficult to program. It may look difficult and there's lots going on, but if you break it down per spindle or slides and positions individually, the programming is fairly basic. The key to success is making sure that the process is balanced, meaning that you don't have one position which takes twice as long as the rest because you’ll see bottlenecks.

Economan: When people think about a multispindle machine, they often think it’s only good for larger lot sizes, like a minimum of 50,000 pieces. But an Index multispindle can be beneficial for part runs as low as 2,500 to 5,000 pieces. These machines have quick-change options from pre-setting, tooling, and workholding to accommodate as many different environments as possible.

Index, us.index-traub.com

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada