Contributing Writer

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

High-pressure additive manufacturing production

Oil and gas industry is filled with AM possibilities

- By Lynn Manning

- January 31, 2022

- Article

- Metalworking

Historically, O&G companies implement expensive inventory programs because average manufacturing lead times are not compatible with on-site operational needs.

Keeping oil and gas (O&G) production facilities running smoothly is a widely acknowledged challenge. Critical process-control components inevitably fail under the stresses of the high-pressure, severe service conditions in these environments.

Historically, O&G companies implement expensive inventory programs because average manufacturing lead times are not compatible with on-site operational needs.

Current inventoried parts often are the same ones chosen when the facility was first designed, and replacements may no longer be available from the manufacturing shop. Opportunities to upgrade a component’s design or materials as operating requirements change, or next-generation designs are introduced, are limited at best. As a result, reliability problems continue and, in some cases, get worse over time.

Compounding these issues is the fact that many of these sites also are in remote or difficult-to-access locations, such as offshore and the Arctic, which makes service and field support problematic. How can you reliably and quickly provide key parts to facilities in distant corners of the world unless you have stockpiles of inventory at every location?

AM Potential and Obstacles

O&G operators have become increasingly open to considering metal additive manufacturing (AM) as a potential answer to such challenges as inventory control and geographic roadblocks.

There remain, however, some significant obstacles to the widespread adoption of AM in the O&G industry.

Most existing metal AM technologies require extensive knowledge of printing parameter development, which sometimes can be a labour-intensive process and result in challenges to efficiently and rapidly adapt to changing geometries and features. These systems also often require significant redesign of a part for it to be “printable.” Additionally, data from the printing process usually is not available, which is critical to assess the quality of the end part.

A print file set up on one AM machine typically can’t be used on another one without some form of user intervention. The result can be an ever-changing file based on individual machine calibration. This creates a digital inventory challenge similar to the current physical inventory one that O&G operators are already dealing with.

API Guidelines for AM

To date no guidelines from the American Petroleum Institute (API) for the procurement or specification of AM materials have been published.

“This has been a challenge for users interested in applying more advanced industrial AM technology to applications where the speed and quality it can deliver would be beneficial,” said Steve Freitas, R&D director, IMI Critical Engineering, Birmingham, U.K. The global company designs, manufactures, and installs customized engineered flow control systems for new plant builds and provides comprehensive plant life cycle service support.

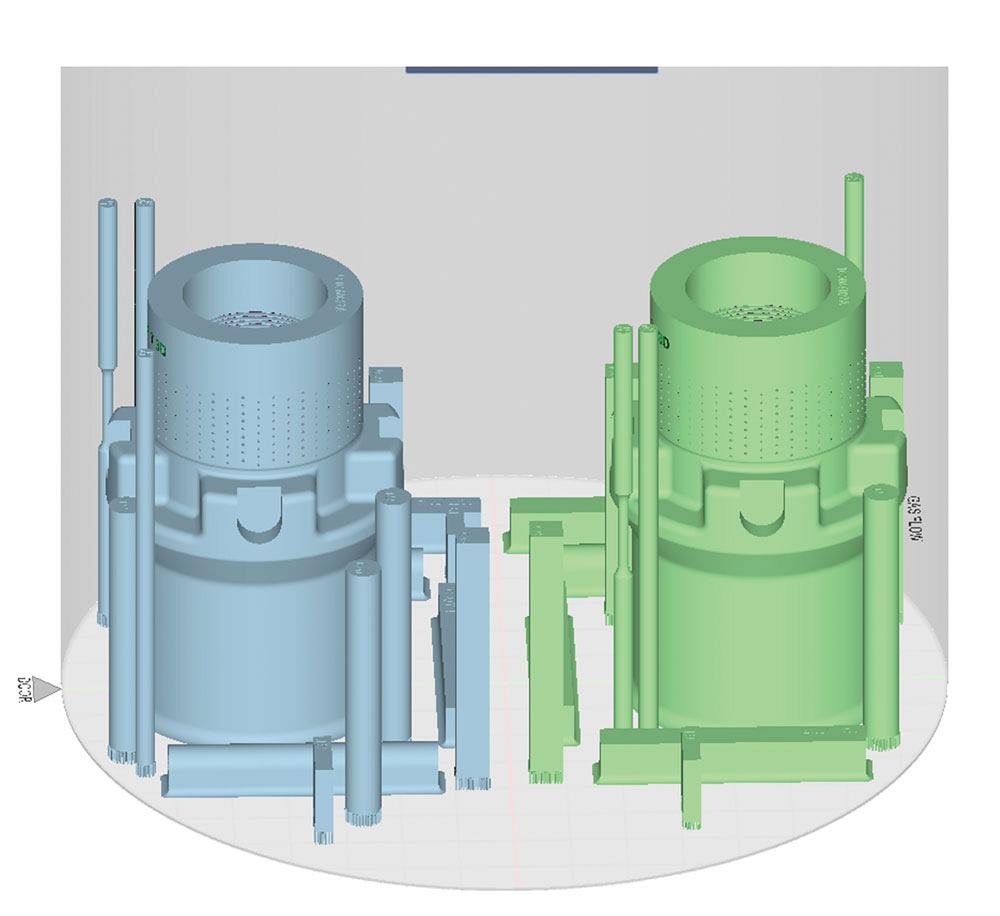

Fig. 1. Two choke valves, optimized with IMI Critical’s DRAG technology, are pictured in a VELO3D Flow software build file.

However, guidance is now on the way in the form of API 20S, the first industry-sanctioned specification for O&G metal AM work. This specification spells out the processes, testing, documentation, and traceability for manufacturers of metal AM components being used in O&G facilities.

While not detailing complete success criteria (required mechanical and non-destructive testing acceptance criteria), API 20S does outline what kinds of testing and validation are required depending on different risk levels within an O&G operation.

A Partnership to Production

AM system manufacturer VELO3D, Campbell, Calif., provided technology to IMI Critical to create first-article component builds intended for field service that are of Additive Manufacturing Specification Level 3 quality. The parts, which also meet draft API 20S requirements, were printed on one of the company’s Sapphire AM systems operated by contract manufacturer Knust-Godwin, Katy, Texas.

The long-term goal of the joint project is to build a compendium of measured field data that will support the path toward certification of production parts for AM as well as the future establishment of more exact specifications for material properties and test methods.

The more immediate benefits of IMI Critical’s work with VELO3D became clear as the project progressed from idea to working parts.

AM Choke Valve Cage

For the team project, a customer selected a commonly installed choke valve cage as a test part. It typically is manufactured with slotted holes for ports, which can have problems with vibration and damage caused by trim erosion in high-pressure-drop operations.

The flow-control industry has evolved considerably between the time this legacy part was created and today. One innovation is IMI Critical’s DRAG system, which consists of an array of discrete, multistage flow paths that control fluid velocity and prevent problems with vibration and trim erosion. IMI Critical, which has produced metal AM components for years, saw this part as a business opportunity to replace a part on demand, but also to improve the performance of its DRAG system.

The next step was to assess the new design for 3D printing (see Figure 1) out of INCONEL alloy 718.

“VELO3D’s early review of our cage design produced valuable recommendations on how to improve the quality of both the as-built AM part and the final, post-processed machined part,” said Freitas.

Getting Ready to Print

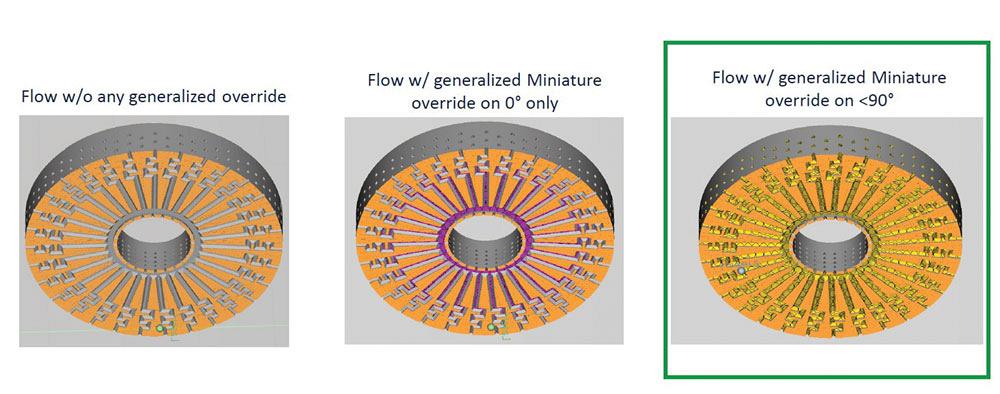

With the CAD design for the part complete, it was now time to move to AM work. The VELO3D Flow print-preparation software automatically responds to a part’s geometry without any complex, part-specific parameter development. The software does this by applying a generalized set of recipes based on the design’s native CAD geometry and user-defined inputs relating to surfaces of importance. This allows design engineers to focus on their desired end-part functionality above all, without the need for pre-print parameter manipulation.

The designer also uses the software to apply and test different surface-refining sub-processes to choose the best one (see Figure 2). This helps create first-article production quickly, but it also creates a standardized framework for future builds.

“This opens up the ability for design and manufacturing engineers to more easily and efficiently implement metal AM printing,” said Zach Walton, VELO3D director of energy solutions, who worked closely with IMI Critical on the project.

QC Throughout the Print Process

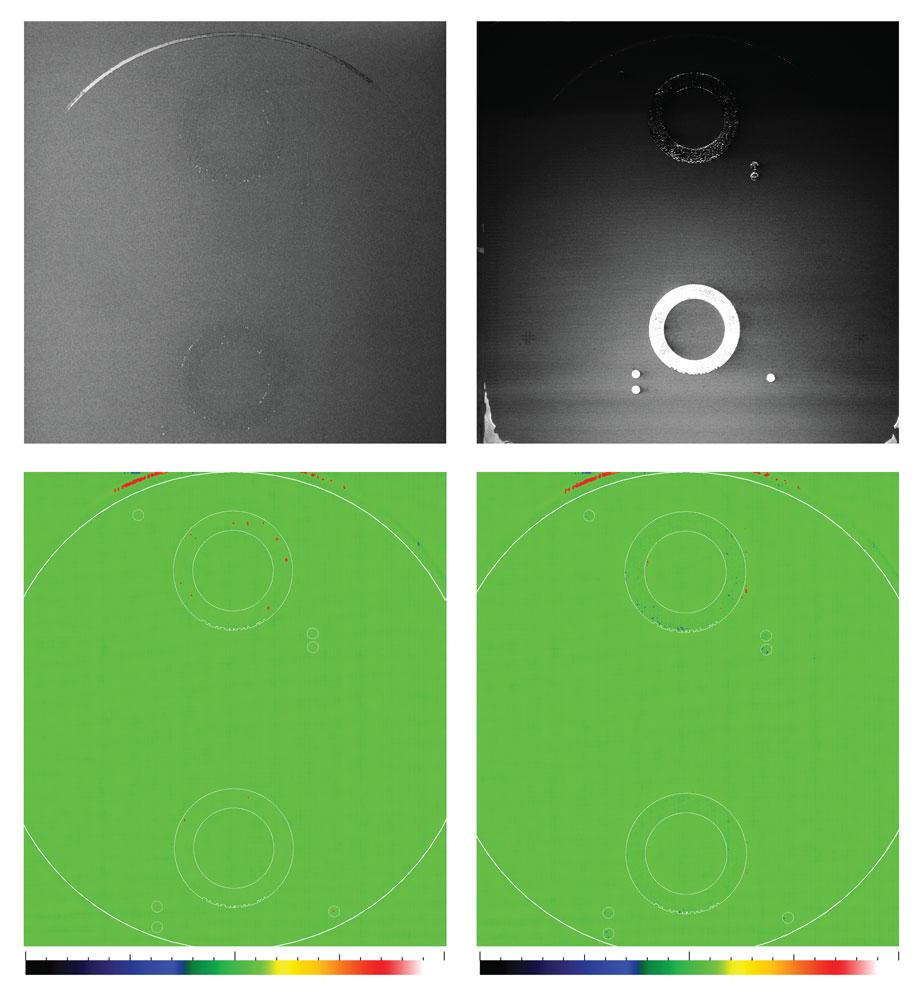

With API 20S requirements always in mind during the project, the partners found that the automation the software’s internal quality control technology provided was beneficial. The software’s Assure component compiles data along with a tremendous amount of information collected throughout the build, layer by layer, then automatically generates a build report containing the QC information, including both raw data and height-mapper images (see Figure 3).

“The raw data and height-mapper images also are useful for evaluating and assessing critical areas of the part for future production,” said Walton.

It’s these options that allow parts to be printed on any VELO3D system no matter who is operating it or where it is in the world with the same expected end-part quality.

“These capabilities of advanced AM now make digital warehousing and on-demand part replacement achievable,” said Walton.

Knowing that the print file created during the project can be reprinted on any system anywhere now provides tangible support for the development of more robust supply chains as O&G operations start leveraging metal AM for replacement or improvement of legacy parts.

“Now we can help our customers reduce inventory requirements while providing opportunities to optimize both the functional characteristics and the materials of critical process-control components,” said Freitas. “This allows O&G operators to shift their focus away from repair and part supply chain problems and concentrate on improving plant reliability and controlling costs.”

The two first-article choke valve components were printed at the Knust-Godwin facility (see Figure 4a). From there the valves were removed from the build plate along with the API 20S test specimens. The valves were then machined to final finish (see Figure 4b) while specimens were tested in accordance with API 20S, which showed compliance to IMI Critical’s materials specification.

The valves were then flow-tested at IMI Critical (see Figure 5) before being delivered to the O&G operator for use in field trials.

Fig. 3. Shown are actual layer-by-layer build photographs inside a Sapphire metal AM system, including (top left) powder bed after recoat and (top right) powder bed after lasing. Individual-layer height-mapper software images show powder bed after recoat (bottom left) with a uniform surface for lasing, and powder bed after lasing (bottom right), providing observation of part performance and a safe environment for the next recoat.

“IMI Critical has a vision to offer its operator-customers much more than just legacy-part replacement,” said Walton. “They really want to move existing capabilities forward by continuing to replace outdated parts with updated technology that provides optimal performance.”

IMI Critical is finding that operators whose legacy OEMs can no longer replace those aging designs are becoming more open to technologies like DRAG and AM—but they are also demanding those new parts as quickly as possible.

“Here’s where AM can dramatically change the picture,” said Walton.

With initial testing and analysis already deemed successful, these parts now are in the field at an O&G operator. Production builds are currently ongoing, leveraging the manufacturing plan established during the first-article build. Additional field testing also will be performed to collect more operational data. The result will be production-ready components, adhering to current API 20S draft objectives, that will be put through real-world field trials at one of the operator’s sites.

Next Steps

Following installation and testing of the new choke valve cages in the field location, results will be published and presented. Going forward, IMI Critical intends to further implement AM technology for the manufacture of additional trim valves and other types of components.

“The ability for metal AM to deliver highly customized parts from robust metal alloys, in far less time than the traditional supply chain, is a benefit that we have been offering to our customers for some time,” said Freitas.

According to Freitas, further advantages from the use of advanced AM will accrue to IMI Critical’s own design exploration work, thanks to VELO3D’s ability to manufacture internal channels and overhangs at well below 45-degree angles (even down to zero in the case of IMI Critical’s DRAG technology). This will enhance the application of DRAG to optimize legacy designs and simplify workflows.

IMI Critical also is planning to leverage the bigger-build platform of the XC AM system for larger flow-control elements or greater volumes of smaller ones.

Contributor Lynn Manning is a science and technology writer based in Providence, R.I.

All figures courtesy of VELO3D.

Fig. 4a . Two choke valves are shown on the build plate after being 3D-printed (4a) and after finishing (4b).

IMI Critical Engineering, www.imi-critical.com

Knust-Godwin, www.kgsbo.com

VELO3D, www.velo3d.com

About the Author

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

GF Machining Solutions names managing director and head of market region North and Central Americas

Mitutoyo updates its end-user portal

Enhance surface finish with high-speed machining

- Industry Events

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada