Canadian Sales Manager

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Do you have the need for speed?

High-speed milling is a valuable addition for many shops

- By Carl O'Brien

- May 31, 2023

- Article

- Metalworking

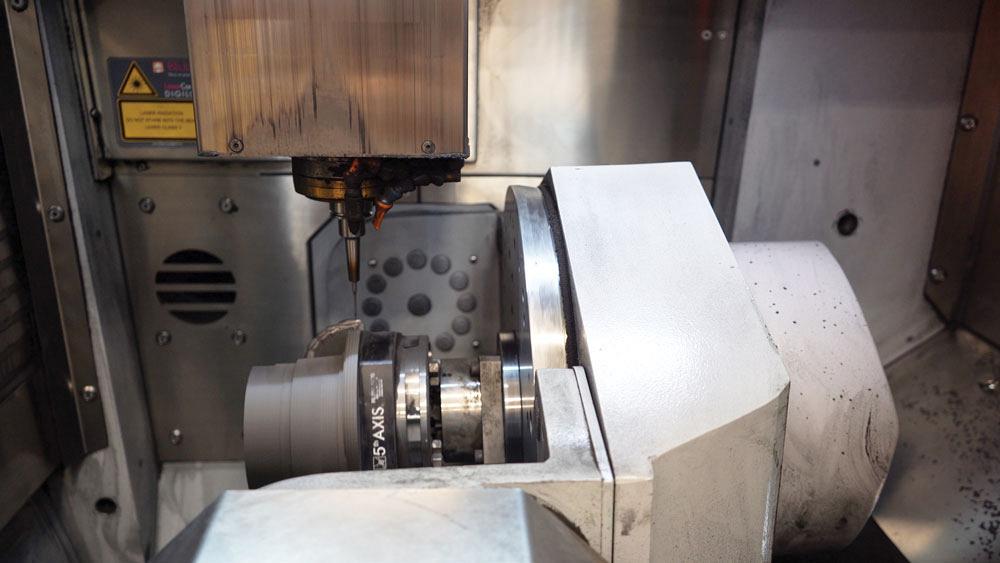

Integrating high-speed milling (HSM) into your shop is an efficient and cost-effective way to increase productivity for machine shops of all sizes.

Even specialty manufacturers, such as those using HSM to make EDM electrodes or those finishing dies and molds, have found this machining method lowers production costs, improves quality, and shaves off production time.

Initially, HSM was primarily used in the die/mold industry, but it has become much more widely used in other industries, including aerospace, automotive, micromachining, and both precision components and general machining.

What Is HSM?

To best integrate HSM, it can be helpful to fully understand what it is and how it works.

HSM is a metal cutting process that emphasizes high speeds and feeds to increase productivity and improve surface quality. HSM dials in a higher spindle RPM, uses smaller tools, and takes shallower cuts than traditional milling operations. HSM usually is associated with any spindle speed above 15,000 RPM, but it is much more than just a faster spindle.

Changes in guideway designs and improved controller processing capabilities play a key role in a machine’s ability to perform HSM.

While traditional machine tools have typically used boxway systems to improve rigidity, many high-speed machine tools use linear guideways.

Linear way systems reduce friction and generally are more accurate while also accommodating lighter loads.

Controllers with advanced look-ahead technology also reduce cycle times. Look-ahead simply does what it implies, looking ahead of the data and maintaining the highest feed rate possible without compromising part accuracy. It’s as if an operator was constantly adjusting a feed override dial thousands of times a second to increase feed, when possible, and decrease it when it is required to maintain accuracy.

By past standards, most new machining centres would now be considered a high-speed machine.

Advancements in technology have pushed spindle speeds to more than 100,000 RPM. To accompany the higher-speed spindles, the look-ahead capabilities of modern control systems continue to increase the potential of high-speed machining centres. Even with higher-speed spindles, some machines still use boxways or other more conventional guideway systems that make them more suitable for heavy machining than high-speed milling.

The most common uses of HSM are:

- Aerospace manufacturing. HSM is used to manufacture parts for aircraft, such as turbine blades and compressor housings.

- Medical part production. HSM is used to manufacture parts for medical devices, such as implants and surgical tools.

- Automotive industry. HSM is used to manufacture parts for automobiles, such as engine blocks and transmissions.

- Die/mold manufacturing. HSM is used to manufacture molds and dies for plastic injection molding and metal stamping.

Advantages of HSM

The main advantage of HSM is that it allows for much faster machining speeds than conventional machining. This leads to significant time and cost savings, especially for large-scale production runs. HSM also can produce better-quality finishes than conventional machining, because it uses a smaller DOC and smaller stepovers.

Although HSM is more common in finish milling, applying these techniques to roughing cycles lowers cycle times and decreases stress and wear on machine tools. HSM often is used to machine difficult-to-machine materials, such as hardened steels, titanium, and aerospace alloys, and it can also be used to produce very high-quality finishes.

HSM Challenges

The high speeds of HSM cause cutting tools to wear out more quickly, and the process can be more difficult to control than conventional machining. Additionally, HSM can be more expensive to implement because it requires specialized equipment and tooling.

Running cutting tools at a high RPM results in increased heat generated in the cut. However, most materials actually see a reduction in heat at a certain surface speed threshold, because the time the cutting edge spends in the material is greatly reduced.

For example, non-ferrous metals generally see an increase in cutting temperature up to around 1,000 SFM, after which temperatures begin to decrease. Research shows that cutting forces also drop, which is one of the reasons why there is less heat.

High speeds do increase the risk of chatter, however, which can leave poor finishes and accelerate tool wear. To combat this, a scientific approach such as tap testing can be used, in which the resonant frequency of the setup is identified, which locates possible chatter zones.

A simpler way to solve the chatter problem is by using vibration-dampening holders such as hydraulic or milling chucks as opposed to shrink fits, as well as using variable geometry cutters that break up the harmonics of the cutter.

HSM also requires an advanced toolpath, which means you need both a highly skilled programmer and robust software. Additionally, operators will need to take extra care to determine if the implemented process is working successfully and be able to identify any shortcomings before scrapping a part or damaging tools and machinery.

The cost of implementing HSM can be a barrier to entry. It requires expensive machine tools, accessories, and cutting tools that all work in harmony to create an advanced process. Not only is the equipment costly, but oftentimes a machinist capable of creating and implementing these processes can come at a higher cost.

Machine Differences

High-speed machines have several distinguishable features from conventional machining machines:

- Spindle Speed. HSM equipment typically has much higher spindle speeds.

- Power. HSM may require more powerful motors than conventional milling machines. This allows them to generate the high spindle speeds and feeds required for HSM.

- Machine Frame. These machines typically have much stronger machine frames than conventional machining centres. This is because they are designed to withstand the high forces and vibrations generated by HSM.

- Bearings. This equipment typically has much more precise bearings than conventional machining centres. This is because they are designed to withstand the high speeds and feeds required for HSM and they typically have cooling systems designed to reduce thermal expansion to maintain accuracy.

- Coolant System. HSM requires a much more sophisticated coolant system than conventional machining. Options such as minimum quantity lubrication (MQL) commonly are found on high-speed machines.

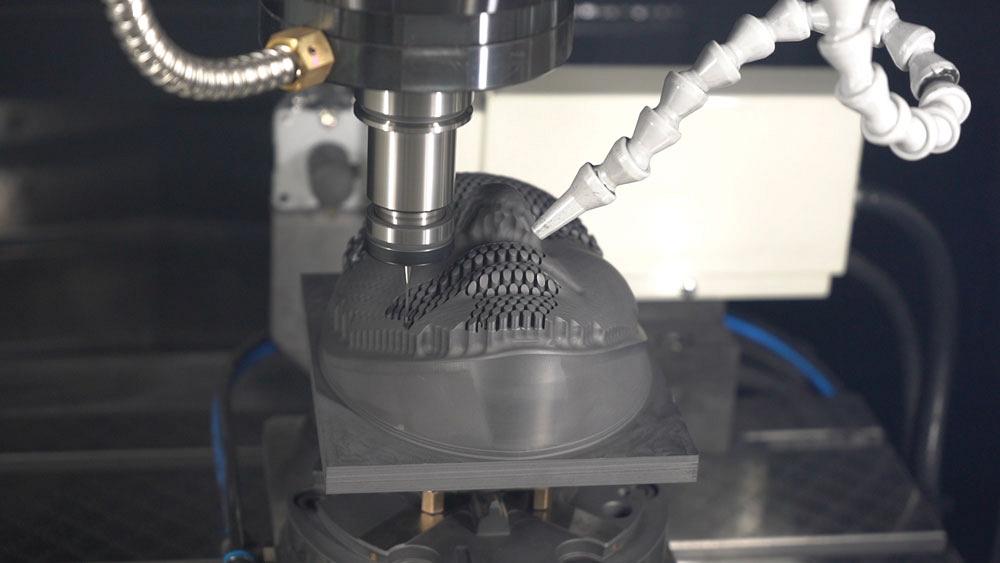

Tooling Requirements

HSM requires special tooling that can withstand the high speeds and feeds used in the process.

The tooling and workholding requirements for HSM are more demanding than those for conventional machining because the high speeds and feeds used in HSM can cause the workpiece to chatter, which can lead to inferior-quality finishes and tool damage.

Key considerations for tooling and workholding for HSM include the cutting tools themselves, the workholding, and the toolholding.

Cutting tools must be able to withstand the high speeds and feeds used in HSM. Coated solid-carbide tools are the most common type of cutter used in HSM. CBN tools also can be used because they have a very high wear resistance and can create better finishes since there is no risk of changing tools in the middle of a part and needing to blend surfaces.

The workholding must securely hold the workpiece in place to prevent it from flexing and chattering.

Toolholding technology, such as collet chucks and hydraulic chucks, are a good choice for HSM because they dampen vibrations. Holders should be balanced before being put in a machine to reduce vibrations and improve accuracy.

At the end of the day, the desired surface finish affects the choice of tooling and workholding. Lighter cuts and smaller stepovers are required to create the best finish possible, and this is done efficiently at high spindle speeds.

The cost of tooling and workholding also can be a major factor in any decision to use HSM. HSM tooling is typically more expensive than conventional machining tooling.

HSM Toolpaths

HSM toolpaths are the paths that the cutting tool follows as it removes material from the workpiece. The design of the toolpath has a significant effect on the quality of the finished product and the productivity of the machining process.

A number of different toolpaths can be used in HSM. Two common ones are:

1. Constant Engagement Toolpaths. These toolpaths maintain a constant engagement angle between the cutting tool and the workpiece. This type of toolpath often is used because it creates smooth surfaces that blend together through different geometries.

2. High-efficiency Milling (HEM) Toolpaths. These toolpaths are designed to create a constant cutter engagement over the length of a cutter’s peripheral cutting edge. The constant chip width creates even cutting forces and makes tool wear and surface finish predictable and consistent.

The choice of toolpath for a particular application depends on several factors, including the type of material being machined, the desired surface finish, and the productivity requirements.

Coolant Strategy

HSM presents a challenge when it comes to coolant, because the high heat that is generated can lead to thermal shock and premature tool wear.

There are three main coolant strategies for high-speed machining: Using water-soluble coolants, employing MQL, and dry machining.

Using water-soluble coolant can be tricky. Although flood coolant is common in many machining operations, it is often avoided when using high spindle speeds. This is because of the water-soluble coolants having a larger thermal conductivity, which rapidly cools the tool. However, coolant manufacturers constantly are developing new technologies that enable water-based coolants to be used for HSM.

Dry machining often is used in hard milling because it avoids the problems that arise from rapidly cooling tools and causing thermal shock. Typically, an air blast is applied to the tip of the cutter to reduce heat while also removing chips from the cutting area.

MQL uses a very small amount of cutting oil blasted with air. MQL can be used as a nice “middle ground” because it provides good lubrication to the surface without causing rapid cooling.

The choice of coolant strategy depends on the specific application, and coolant manufacturers have different coolants based on material, type of machining being performed, and the cutting tools being used.

Surface Finishes

HSM produces very smooth surface finishes, as long as the machining parameters are properly set. Many factors affect the surface finish produced by HSM.

The cutting tool’s geometry has a significant effect on the surface finish. Geometries such as rake angle, helix angle, and relief angles all determine how clean the material is sheared, leaving a smoother finish, but they also determine how quickly a tool wears or even breaks when cutting certain materials.

The cutting speed is one of the most important factors that affect the surface finish produced by HSM. Higher cutting speeds reduce cutting forces past a certain threshold, which can result in smoother finishes.

Careful consideration must be made when choosing a feed rate, because the chip load (feed per tooth) directly affects the surface finish. A larger feed per tooth gives a rougher surface, but if a tool is fed too slowly, burnishing can occur leaving undesirable finish and causing premature tool wear.

As mentioned, the use of coolant also affects the surface finish produced by HSM. Coolant helps to reduce heat and vibration, both of which help improve the finish.

Carl O'Brien is Canadian sales manager for MC Machinery Systems Canada, 50 Vogell Rd., Unit #1, Richmond Hill, Ont. L4B 3K6, 905-737-1265, www.mcmachinery.com.

About the Author

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

Mitutoyo updates its end-user portal

- Industry Events

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada