Technical Advisor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Upgrade your grades

Cutting tool innovations create production efficiencies

- By Andrei Petrilin

- February 26, 2021

- Article

- Cutting Tools

Most insert production starts with carbide powder (shown here), and new grades are making an impact in metal cutting.

Building a house begins with laying the foundation. The strength and reliability of the whole house depend on how strong the foundation is. In cutting tool engineering, the foundation is the cutting material.

Numerous types of cutting material exist, including cemented carbide, polycrystalline diamond (PCD), high-speed steel (HSS), and ceramics, and each type contains different grades.

Cutting Material History

At various stages in metal cutting history, the introduction of a new cutting material led to a significant change in the level of cutting speeds and, consequently, productivity. The previous century, especially its second half, was marked by the rapid progress of tool materials. Today, however, we do not see many significant new advances in this field. Does this mean that the development of new tool materials has already reached its peak and is experiencing stagnation? Of course not.

It is simply that new developments are occurring deep within the cutting material and are focused on its structure, and they can be observed only with the help of scanning electron microscopy (SEM), X-ray diffraction (XRD), electron backscatter diffraction (EBCD), and other sophisticated methods. New developments often take the form of new coatings, which are extremely diverse despite their extreme thinness, which is measured in microns.

Carbide Guide

The most commonly available cutting material today is cemented carbide, which primarily is coated. In terms of performance, cemented carbide offers a reasonable balance between efficiency, tool life, and cost.

A carbide grade comprises cemented carbide, also known as hard metal, tungsten carbide, and simply carbide; a coating; and a post-coating treatment. Only one of these components, the cemented carbide, is an essential element in the grade. The others are optional.

Cemented carbide is a composite material of hard carbide particles that are cemented together by a binding metal (mainly cobalt). Most cemented carbides used for producing cutting tools also have wear-resistant coatings. Numerous treatment processes also are applied to the coated cemented carbide, such as the rake surface of an indexable insert.

New developments in cemented carbide as a tool material are concentrated in three areas:

- Carbide production technologies.

- Advanced coating methods.

- Post-coating techniques.

Considerable success has been achieved in each of these fields, and this is reflected in the wealth of new products recently introduced to the market by leading cutting tool manufacturers.

Cutting tool end users typically analyze grades using parameters such as productivity, tool life, and performance. Indeed, the question of how a new product was created to meet their requirements usually fades into the background as applicability and efficiency form the main measure of progress from a shop’s point of view.

When upgrading carbide grades, tooling suppliers need to be sensitive to the challenges the metalworking industries face.

Take, for example, difficult-to-cut materials such as titanium, heat-resistant steels, and exotic superalloys. Recently the share of their application in industry has increased significantly. Along with the aircraft industry, a traditional consumer of these materials, they may be increasingly found in power engineering, automotive, and oil and gas branches.

The growing use of these materials demands technological innovation in both machinery and cutting tools. The new tools require an appropriate foundation, made of advanced cutting tool materials, to achieve the desired cutting geometry.

In addition to cemented carbide, the metalworking industry consumes other hard cutting materials, such as ceramics, diamond, and cubic boron nitride (CBN). Their use in machining difficult-to-cut materials facilitates considerable increases in productivity. Example applications for these new non-carbide grades include SiAlON grades for cutting high-temperature alloys and the CBN grades for hard-part turning.

Customer demands are not limited to the effective machining of exotic superalloys or titanium, either. Steel still is the main structural material, and cutting tool manufacturers constantly are searching for the most advanced appropriate answers, including the development of advanced cutting material grades.

New grade technology available

Application-specific grades increase productivity

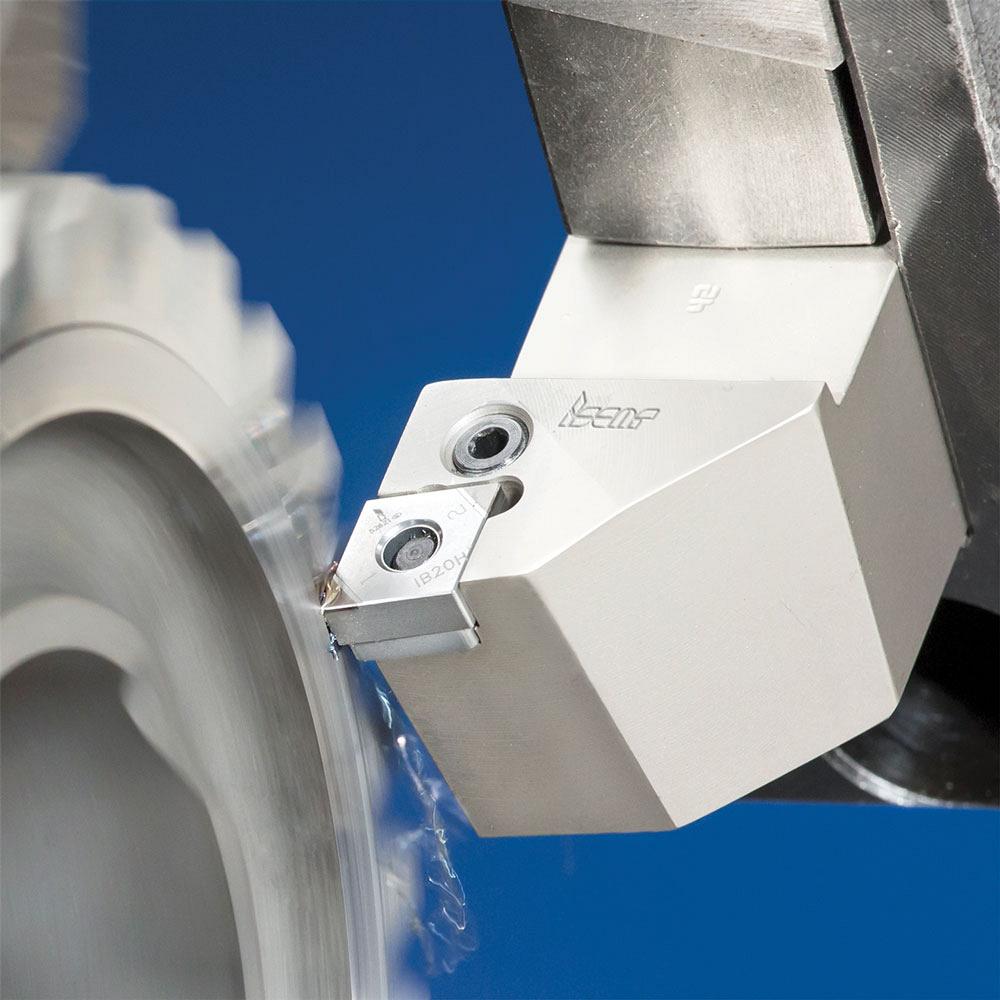

Iscar has developed the PVD-coated IC882 and CVD-coated IC5820 carbide grades for cutting titanium, high-temperature alloys, and stainless steel. An integral component of these grades is a post-coating treatment that lengthens tool life because of its increased resistance to chipping, notch wear, and built-up edge formation. The IC882 grade is suitable for difficult machining conditions, and the advantages of the IC5820 grade are most evident when it’s used for milling with pinpointed high-pressure coolant.

For drilling applications, the company introduced IC5500, a new grade that has a multilayer CVD coating and a post-coating treatment to prolong tool life. It has been used in the company’s milling products as well as its new round insert for machining 3D surfaces, such as blades in turbomachinery.

The company also has developed the PVD-coated IC806 carbide grade, which was specifically designed for turning high-temperature superalloys. It also recently was applied to laydown threading inserts.

Andrei Petrilin is technical manager for Iscar Tools, 2100 Bristol Circle, Oakville, Ont. L6H 5R3, 905-829-9000, www.iscar.ca.

About the Author

Andrei Petrilin

2100 Bristol Circle

Oakville, L6H 5R3 Canada

905-829-9000

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI