Technical Advisor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Tailoring tools for cast iron

Deemed an easy-to-machine material, cast iron still has its own challenges

- By Andrei Petrilin

- September 10, 2020

- Article

- Cutting Tools

Figure 1. For hard turning applications, Iscar expanded its range of CBN-tipped, ISO-type inserts for both continuous and interrupted cutting.

Cast iron machining typically is not considered to be problematic. This premise is partly because of the material’s higher graphite content when compared to steel’s.

Graphite makes the chips brittle and short and possesses anti-friction properties that contribute to cutting edge lubrication. And with its ability to absorb vibrations, graphite also improves machining stability.

While these are definite advantages, the nuanced world of cast iron demands a more detailed study.

Machining Cast Iron

As can be construed from its name, cast iron is intended for castings.

Machining cast iron parts involves removal of non-uniform and variable stock, for example, sand inclusions, casting skin, blowholes, hot tears, and other casting defects that affect cutting tools.

From a machining standpoint, the higher graphite content also has a disadvantage: it accelerates abrasion wear. The cutting tools being used, therefore, must have good wear resistance to ensure high productivity.

It is also worth noting that the term cast iron may in fact refer to different types of ferrous alloy, for which machinability can vary significantly. The latter is often neglected, which can lead to the wrong cutting tool choice and incorrect definition of cutting data.

There are several types of cast iron. Grey, nodular, and malleable cast iron form the application group K (red identification colour) in accordance with the ISO 513 standard classification. Hardened and chilled cast iron relate to group H (grey identification colour). These specifications offer clear guidelines for manufacturers regarding the application of cutting tools with the correct tool material, cutting geometry, and cutting data.

Usually, machining ISO K cast iron is not a problem for manufacturers. Ferritic grey cast iron, for example, is an easy-to-cut material. However, machining ISO H cast iron is more difficult.

Although similar to conditions for machining hard steels, the material’s specific features demand specific cutting tool features. In addition, some types of cast iron demonstrate a certain duality in their machinability, emphasizing the broadness and heterogeneity of the definition "cast iron."

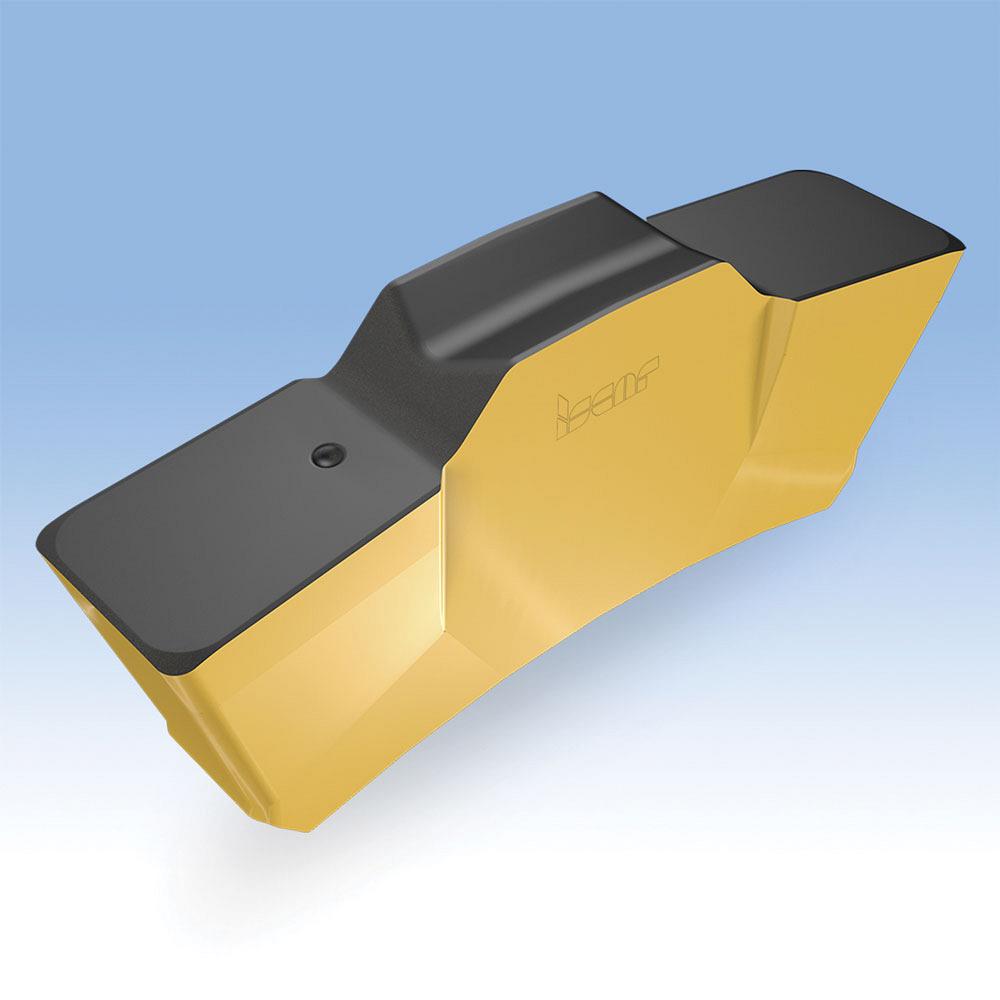

An example of an optimized edge condition in combination with a carbide grade, which is dedicated for machining cast iron, is the TGMA grooving insert. The frontal and side areas of the insert cutting edge feature the chamfered condition forming a so-called T-land to increase the edge strength and extend tool life. Computer modelling played a crucial role in optimizing the edge geometry. The insert is made from the CVD- coated carbide grade IC5010 that was developed especially for grooving cast iron.

For example, machinability of Ni-resist cast iron can be compared with grey cast iron; however, the required cutting geometry seems more suitable for austenitic stainless steel. Workpieces from austenitic ductile iron (ADI) are delivered in different material conditions and hardness levels that impact the selection of cutting tools. Machinability of ADI before hardening is sufficient and is similar to cutting high-alloy steel. Nevertheless, if this cast iron is machined in a high-hardness condition, only the tools intended for the ISO H application group will meet expectations.

The Hardness Challenge

The situation with cast iron of high hardness in the ISO H group is challenging. Machining cast iron with a hardness of HB 400 to 440 is usually less of a problem for manufacturers. The picture changes radically, however, when dealing with hard abrasion-resistant, high-chrome cast iron. The general hardness may be around HRC 52 to 54 but in the thin-wall areas of a machined part, the hardness can reach HRC 60 or more.

In combination with the high chrome content, it makes machining extremely difficult and significantly diminishes tool life.

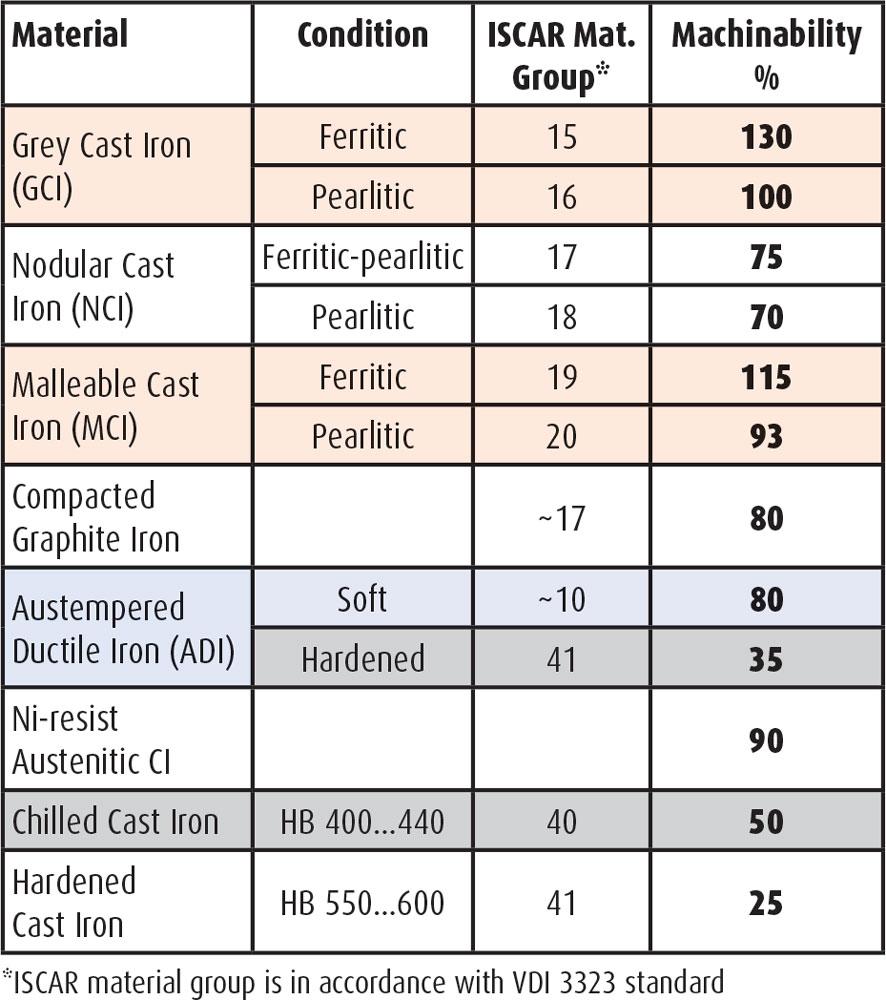

Figure 1 shows the averaged machinability rating for different cast iron types. Pearlitic grey cast iron, which is specified as a 100 per cent rating, provides a base for comparison.

Selecting Tooling

Choosing the most suitable cutting tool for machining cast iron should be based on a detailed study of a cast iron type and its hardness.

Cutting tool application specialists, who are involved in selecting the right tools, need to be fully accurate when specifying characteristics of the cast iron that is intended for machining. In turn, cutting tool manufacturers make every effort to find the most effective way to machine cast iron, taking into account the diversity of the cast iron world.

Among the main consumers of cast iron are the automotive, die and mould, machine tool, and heavy industries, all demanding increasingly efficient products from their cutting tool partners.

Difficult-to-cut hard/high-chrome cast iron produces serious problems for machining productivity. A cutting tool undergoes high mechanical and thermal loading. In milling this cast iron with cemented carbide tools, for example, a typical cutting speed is low, around 130 to 160 SFM. Intensive heat generation often forces manufacturers to apply coolant. As a result, the tool operates under conditions of a heat shock effect, which considerably shortens the tool life.

Grades should have a tough substrate, and some combine medium-temperature CVD and PVD coating processes.

New Insert Technology

A fundamental significant change in productivity can be reached with the use of cubic boron nitride (CBN), which enables a considerable increase in cutting speeds. In machining hard cast iron, for instance, the speeds are two to five times higher when compared with cemented carbide.

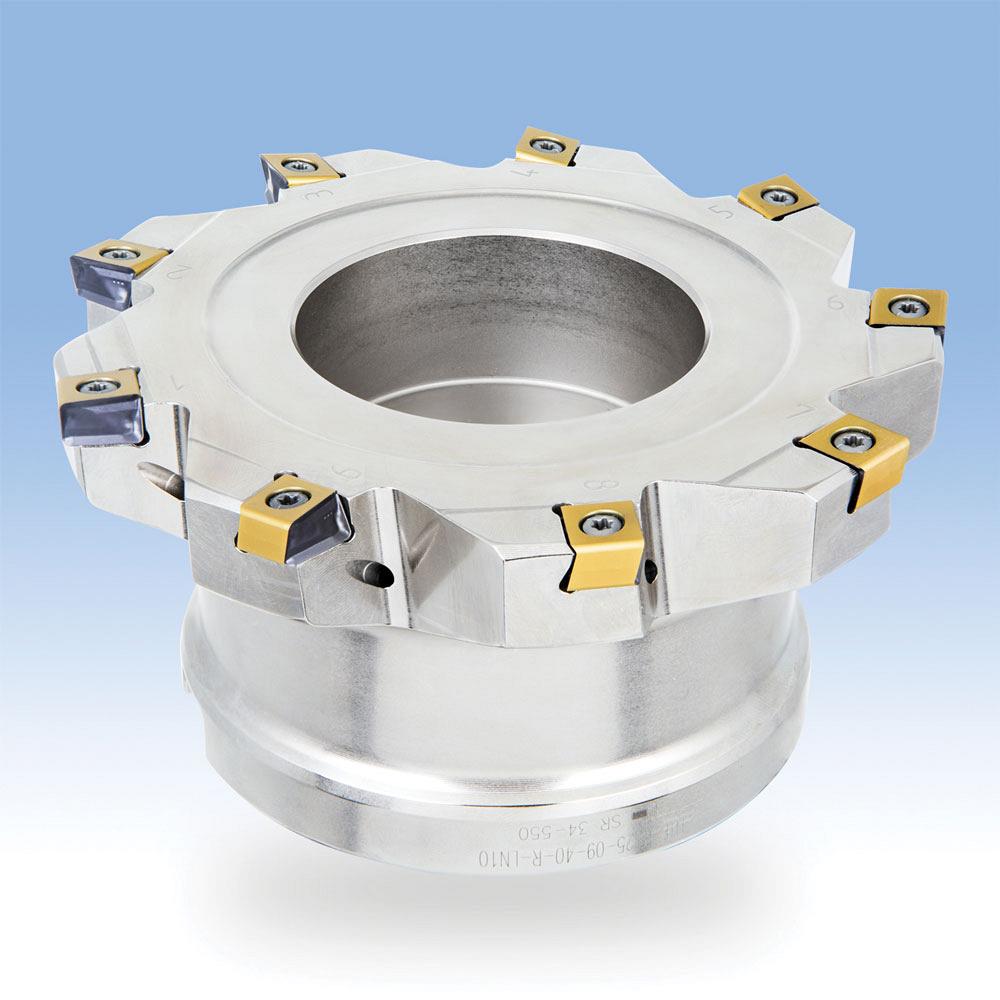

Iscar’s TANGFIN family of face milling cutters are designed to produce an extra-fine surface finish, which has been of great interest to producers of cast iron parts.

This makes high-performance milling cutters carrying tangentially clamped inserts with CBN tips extremely popular in the automotive industry.

In ISO K applications (machining grey, nodular, and malleable cast iron) in medium-duty loading, ceramic tools have demonstrated good results. Peripherally ground, tangentially clamped milling inserts, made from the silicon nitride (Si3N4) with the correct grade, can enable high cutting speeds while providing excellent surface finish. In turning, cutting speeds of up to five times faster can be achieved by using the CVD-coated silicon nitride inserts, even for roughing operations.

The Role of Geometry

Cutting geometry and edge preparation are crucial for good tool performance, and there are several types of cutting edge preparations, including rounded and chamfered. Although selecting the required preparation might appear to be a simple task, it is not so easy.

Which width or angle of chamfering will be the most effective? How do you ensure the defined angle during tool production? These questions are particularly critical when using ceramic or CBN inserts. The answers require appropriate professional skills and experience. Today’s tool engineers are armed with a powerful design instrument, computer modelling of chip formation, that significantly contributes to finding an optimal shape. This instrument considerably shortens developing cutting geometry and represents an important factor in successful tool design.

Extra-fine Finisher

Tangentially clamped inserts that are positioned in a cutter with a gradual displacement in both radial and axial directions cause each insert to cut only a small portion of the material. This concept, together with the high-rigidity tangential clamping principle and the long wiper edge of the insert, results in an impressive machined surface finish, with an Ra up to 0.1 μ (4 μin.) roughness parameter.

Customized Tooling

The automotive industry is one of the largest producers of cast iron parts. In efforts to reduce cost per part in the mass production of automotive components, cutting tool manufacturers have developed customized tools that perform specific machining operations with maximum productivity and lead to a reduction of the non-cutting component of cycle time.

For example, customized technology for the machining of steering knuckles required a fully assembled tool to perform several operations: tapping inner threads for a dust shield, milling two grooves for a snap ring and grease seal using helical interpolation, and milling the outer face. The tool carries different radially and tangentially clamped inserts and has a tapping attachment with a misalignment-compensating mechanism. The strict tolerance limits for linear dimensions ensure successful use of the tool in multispindle machines.

It turns out that machining cast iron is not such a simple matter after all, as is sometimes believed. Understanding the “colourful” world of this material and following the procedures for correct cutting tool application will ensure maximum efficiency and achieve – and sustain -- highly effective machining practices.

Andrei Petrilin is technical manager for Iscar Tools, 2100 Bristol Circle, Oakville, Ont. L6H 5R3, 905-829-9000, www.iscar.ca.

About the Author

Andrei Petrilin

2100 Bristol Circle

Oakville, L6H 5R3 Canada

905-829-9000

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI