- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Complex machining requires advanced software

Ontario precision parts manufacturer grows by pairing new CAD/CAM software with 5-axis machining

- By Canadian Metalworking

- May 1, 2023

- Article

- Automation and Software

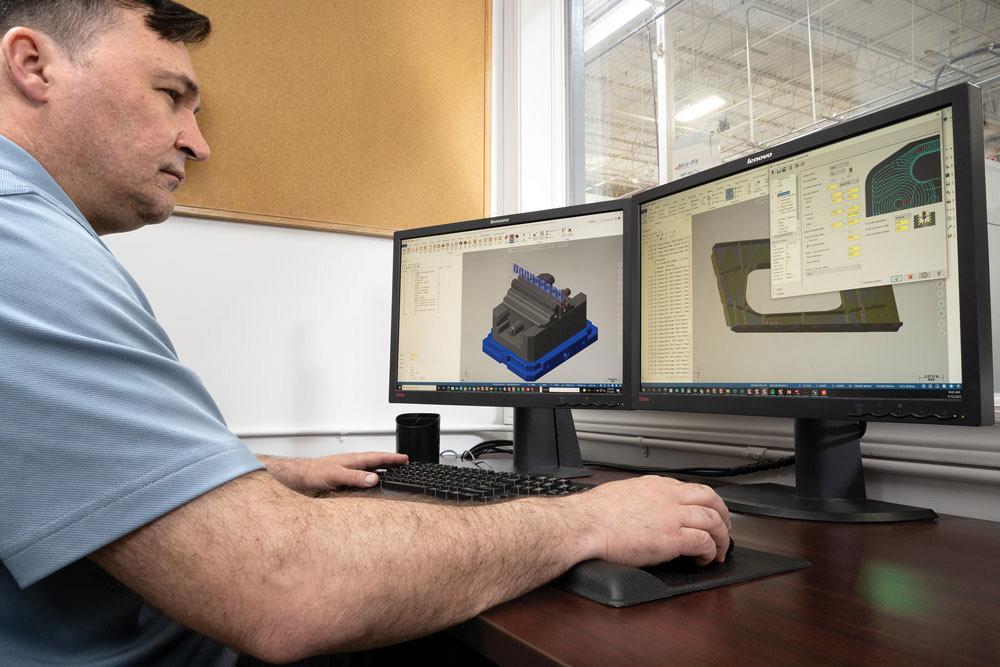

Using Mastercam CAD/CAM software, CNC Programmer Chris Merrick programs toolpaths for a ventilator component. Images: Chris Hayhurst, Hayhurst Photography

Situation

In 2000, Coordinate Industries, Oakville, Ont., upgraded its equipment capabilities by purchasing a single 5-axis machine. Now, more than 20 years later, the company has grown its install base to include 50 CNC machining centres, 26 of which are 5-axis milling machines.

Established is 1985, the company produces precision machined parts for the aerospace, defence, and medical industries, as well as mechanical components for the spectral imaging and visual information industries. They also offer finishing and assembly services. Housed in two campuses totaling 100,000 sq. ft., Coordinate Industries has 151 employees.

Before bringing in more advanced machining technology, Coordinate Industries was a job shop with low production volumes, sometimes running short orders of only two to five pieces. Operations needed to be flexible. The use of Mastercam software was limited to select points on the shop floor.

“When I started, we did all of our programming conversationally at the control,” said Senior CNC Programmer Chris Merrick. “As the parts became more complex, it became imperative that we purchase CAM software.”

Resolution

To optimize its growing equipment investment, the company uses CNC Software’s Mastercam CAD/CAM software.

“There’s a significant difference from now and 20 years ago with how much we’ve improved and what we have achieved. We would not be where we are right now without a solid CAM software,” said Director of Operations Josip Saric.

Adding Mastercam’s advanced CAM software opened the company up to accepting orders with more complex specifications.

One of the first of these new orders involved parts with multiple planes. Although it was possible to incorporate a fixture into one of the shop’s existing 3-axis machines to enable the workpiece to be machined from all sides, it was not cost-effective. The method required multiple setups with the machine’s door being opened each time the part needed repositioning, costing valuable time because of the stoppages.

Instead, the company’s programmers decided to use the 3+2 machining technique that uses a 3-axis program by tilting the part to multiple planes on a 5-axis machine. Using the rotational axes to orient the cutting tool, it can then be tilted at any angle and locked in position. This approach allows a shorter, more rigid cutting tool to be used and enables higher speeds and feeds than conventional 3-axis machining. It also reduced the number of required machining operations.

Conversational programming became too difficult because the new machines could now create more complicated geometries. Not only did the programmers need software for plane creation for 3+2 machining, but they also had future parts planned that included more detailed finishing with tighter tolerances. Because senior operators already had experience and trust built with the software, the company decided to use it to increase programming capabilities.

Josip Saric, director of operations, completes part setup on a DMG MORI DMU 80 eVo machining centre.

“We had the 5-axis [machine] and we were struggling,” Merrick said. “We were making some parts with it, but we weren’t getting what we could out of the machine. Using Mastercam allowed us to make one part in one operation and cut it off, versus four, five, or six operations.”

Now equipped with 26 5-axis machines, the company owns nine seats of Mastercam. Workflow is streamlined by separating the machinist position into two specialized roles. Operators now focus on running the machine efficiently, while programmers work with the software to manipulate the part, put it in position, design workholding, and apply optimal toolpaths.

Manufacturing processes were standardized by incorporating tool libraries, eliminating the need to input data manually. The software has a feature that holds customized parameters for frequently used tools and holders with the ability to assign them into assemblies. Details like cutting specifications can be included and copied to similar components, saving programming time.

Coordinate Industries also improved how it maintains quality control.

Where before the only verification was through first-off inspection, now this process is done in the programming phase prior to production. Programmers use the software’s Verify function throughout the process to simulate generated toolpaths in a virtual environment and check accuracy. This helps prevent costly mistakes by detecting collisions between the stock, tool, and machine before they happen.

The company also takes advantage of the software’s Dynamic Motion high-speed toolpaths, which help lengthen tool life and reduce cycle times.

For example, Merrick described a 7050 aluminum part that is manufactured in one operation using high-speed dynamic roughing, which he said is five times faster than standard pocketing methods.

The front and back faces are created using the software’s Pocket toolpath feature, while the outside profile and pockets are created using 2D, high-speed, dynamic toolpaths. Dynamic Motion uses the full flute of the tool to make cuts, which maximizes material removal and reduces tool wear. The workpiece is then finished with the software’s 2D Contour, Pocket, and Surface Flowline features.

To break sharp edges, the program’s toolpath uses a mix of Deburr and 2D Chamfer, which reduces manual deburring time while maintaining part consistency. Finally, the part is cut off using 2D Contour, leaving 0.003 in. along the holding edge to enable an easy break.

As it did for countless manufacturers, the COVID-19 pandemic spawned new challenges for Coordinate Industries because some of its existing customers were affected economically. Orders from the aerospace industry declined, but orders from the military remained. The manufacturer also discovered new customers in the medical industry that required small jobs with quick turnaround times.

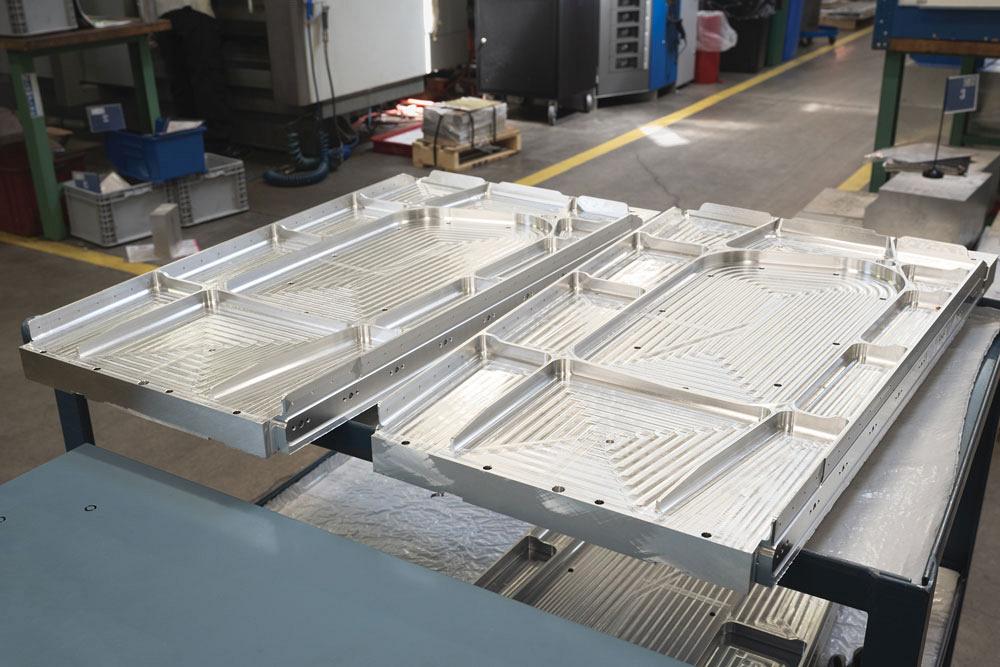

One contract with scheduling constraints involved the production of ventilator components. The customer had first investigated the possibility of injection molding, however, the process of creating the mold and then manufacturing it would exceed its timeline. With the help of its CAD/CAM software, Coordinate Industries was able to quickly design, program, and produce the part to meet customer demand.

“We were able to do it faster than any injection mold company was able to,” said Saric.

While Coordinate Industries typically machines aluminum, the medical parts were made of white polyoxymethylene plastic. The material introduced a new production variant because coolant could not be used to lubricate the machine. Therefore, an air blower was purchased for blowing off the tips to cool down the parts.

The parts had simple geometries and were created in one operation using the Drilling, Contour Ramp, 2D Contour, and Contour Chamfer toolpaths.

“We try to do the medical parts as soon as possible, so we had those down to very short cycle times. For maximum output, the operators placed strips of 23 parts on each pallet and employed lights-out manufacturing,” said Saric.

More recently, the manufacturer started utilizing the software’s OptiRough toolpaths to increase efficiencies for parts with large surfaces. A dynamic, high-speed toolpath, OptiRough continually adjusts the cutting tool motion to optimal conditions. It takes into account radial chip thinning, which occurs when the width of the cut is less than the radius of the tool and leads to uneven tool wear.

To avoid cuts that are too thin, feed rates are increased, allowing a smaller stepover and deeper stepdown to be used. The toolpath makes it easier for programmers by potentially replacing multiple operational steps and reducing programming time.

To stay up-to-date with technology, the company purchased the software’s maintenance program through Mastercam reseller, In-House Solutions, Cambridge, Ont. The program provides access to the latest software versions and new features released throughout the year. Coordinate Industries plans to convert to the latest software release once all employees are trained. To avoid problems with file sharing, the strategy is to switch all departments at the same time.

“We’ve been using Mastercam for so long and our knowledge of the software has grown as the software has also grown,” Merrick explained. “They’ve made many improvements in the software over the years and that’s helped us a lot.”

In-House Solutions assisted with the version upgrade by explaining the software updates. Additionally, the reseller produces the post-processors that may need to be updated for a major release or for a new machine with a different control or configuration, continuing support until the machine has been successfully connected. Coordinate Industries also relies on In-House Solutions to provide training for new employees.

Coordinate Industries, www.coordinate-industries.com

Mastercam, www.mastercam.com

About the Author

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

Mitutoyo updates its end-user portal

- Industry Events

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada