Director of sales and marketing

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Get the most from your portable angle grinder

Selecting the right abrasive wheel type for productivity and safety on your job

- By Pierre Hawkins

- August 5, 2020

- Article

- Metal Finishing

Want to do more work in less time, with less effort? Users of angle grinders can streamline operations and maximize safety by selecting the abrasive wheel type that best suits the grinding or cutting job at hand.

Grinding and cutoff wheels for right angle grinders are available in a range of specifications and types. Wheel specification refers to the composition of the wheel and is primarily determined by the material you are working on. Wheel type refers to the shape of the wheel. Since different wheel types perform better in different tasks, you can improve job productivity by selecting the most appropriate wheel type for your application.

Angle grinders can accommodate several different types of abrasive wheels, including Type 1/41 cutoff wheels; Type 27/42 depressed-centre cutoff wheels; Types 27, 28, and 29 depressed-centre grinding/combination wheels; and Types 6 and 11 cupstones. However, each wheel type requires compatible wheel guards and flanges to ensure safety and proper performance. These parts are not always supplied with the power tool. If not, they usually are available from the tool manufacturer as an accessory. Detailed specifications for proper wheel guards and flanges are described in the ANSI Code B7.1.*

Briefly, here are some of the performance advantages of the wheel types that can be used on properly equipped angle grinders.

Cutoff Wheels (Reinforced Resin Bond)

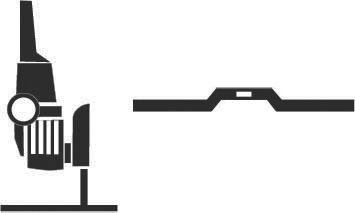

Type 1/41 cutoff wheels, also referred to simply as Type 1 cutoff wheels, are indispensable for all types of cutting and notching applications. These wheels usually range from 0.040 to 1/8 in. thick, and their flat shape allows maximum cut depth.

There are two important safety considerations to keep in mind when using these wheels. First, Type 1 wheels for use on angle grinders must be fully outside-reinforced with fibreglass to resist side pressure in the cut. Non-reinforced wheels, or internally reinforced wheels, should never be used on angle grinders. To ensure safety, use wheels that are clearly labelled for use on angle grinders.

Second, since many angle grinders do not come equipped with flanges designed for thin Type 1 wheels, it is very important to ensure that you are using flanges that meet A.N.S.I. standards. Type 1 wheel flanges should be of equal diameter, centre relieved, with the contact surface at the flange periphery. ANSI also specifies a minimum flange diameter depending on wheel diameter (see ANSI B7.1, Section 5 for full information). Most tool and abrasive wheel manufacturers can supply you with the correct part for your tool.

Depressed-centre Cutoff Wheels (Reinforced Resin Bond)

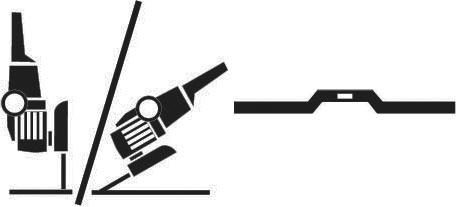

Type 27/42 cutoff wheels, also commonly described as Type 27 cutoff wheels, range from 0.040 to 1/8 in. thick and have a full diameter of fibreglass reinforcing on each side of the wheel to resist side pressure. Designed for cutting only, these wheels must not be used for grinding. Side or angle grinding may cause these wheels to chip or break.

These wheels are used in similar applications as Type 1 flat wheels, but the locking nut of the wheel flange is recessed in the depressed centre of the wheel, so it will not contact the workpiece. This wheel is preferred over the Type 1 wheel where flush cutting on flat surfaces is required.

Depressed-centre Combination Wheels (Reinforced Resin Bond)

Type 27 combination wheels are used for light grinding, notching, root pass grinding, and cutting. These wheels are usually 1/8 to 5/32 in. thick. They are fiberglass-reinforced on the back and in the centre of the wheel, facilitating both grinding and cutting.

This is the wheel of choice for pipeline fabrication and any job that requires alternate grinding and cutting operations, eliminating the need for changing wheels.

Depressed-centre Grinding Wheels (Reinforced Resin Bond)

Type 27 grinding wheels, usually ¼ in. thick, are used for operations such as weld bead grinding, bevelling, and general stock removal. These wheels are fully reinforced with fiberglass, making them more durable than non-reinforced grinding wheels, such as Type 6 and 11 cup wheels.

Type 28 grinding wheels have a conical, or saucer, shape that creates a built-in grinding angle. You can hold the grinder at a shallower, more comfortable angle without sacrificing grinding efficiency. This reduces fatigue while maintaining aggressive grinding action. These are ideal for grinding large convex surfaces such as pressure vessels. Some new, ergonomically designed variations on these wheels feature a steeper, 20-degree grinding angle, allowing you to keep your elbow lower and shoulder more relaxed than you would with the traditional Type 28.

Type 29 depressed-centre wheels are normally semi-flexible grinding/finishing wheels. The convex wheel face of this type facilitates work on contoured surfaces. The combination of wheel flexibility and the curved wheel face is ideal for grinding, blending, and finishing of the workpiece.

Cup Wheels (Non-reinforced Resin Bond)Type 6 and 11 cup wheels, popularly called cupstones or cup rocks, are good for heavy stock removal applications. They are used for grinding and snagging in foundry, forge, and primary metal production, as well as concrete. These wheels offer long life and a broad grinding surface when applied at shallow grinding angles.

These wheels are not fiberglass-reinforced so, as with all abrasive wheels, strict adherence to ANSI B7.1 is required for safe operation. It is very important to note that these wheels require a specially designed adjustable grinder guard that is not normally supplied with angle grinders (for guard specifications see ANSI B7.1, Section 4.2.2.2). For many users, a fiberglass-reinforced product may be a preferred alternative if it fits their application.

Careful selection of both abrasive wheel type and specification can reduce both material and labour costs. Check with your supplier for further recommendations on your specific work.

Pierre Hawkins is director of sales and marketing, Flexovit USA Inc., 1305 Eden-Evans Center Rd., Angola, N.Y. 14006, 716-549-5100, phawkins@flexovitabrasives.com, flexovitabrasives.com.

* ANSI B7.1, American National Standard, Safety Requirements for the Use, Care and Protection of Abrasive Wheels, published by Unified Abrasives Manufacturers Association, 30200 Detroit Road, Cleveland, Ohio 44145-1967>

About the Author

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Aluminum MIG welding wire upgraded with a proprietary and patented surface treatment technology

Achieving success with mechanized plasma cutting

Hypertherm Associates partners with Rapyuta Robotics

Brushless copper tubing cutter adjusts to ODs up to 2-1/8 in.

Gema welcomes controller

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI