General manager, RADAN Americas, production software

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

The potential of CAD/CAM nesting

How to get the most out of your nesting software

- By Doug Wood

- February 26, 2020

- Article

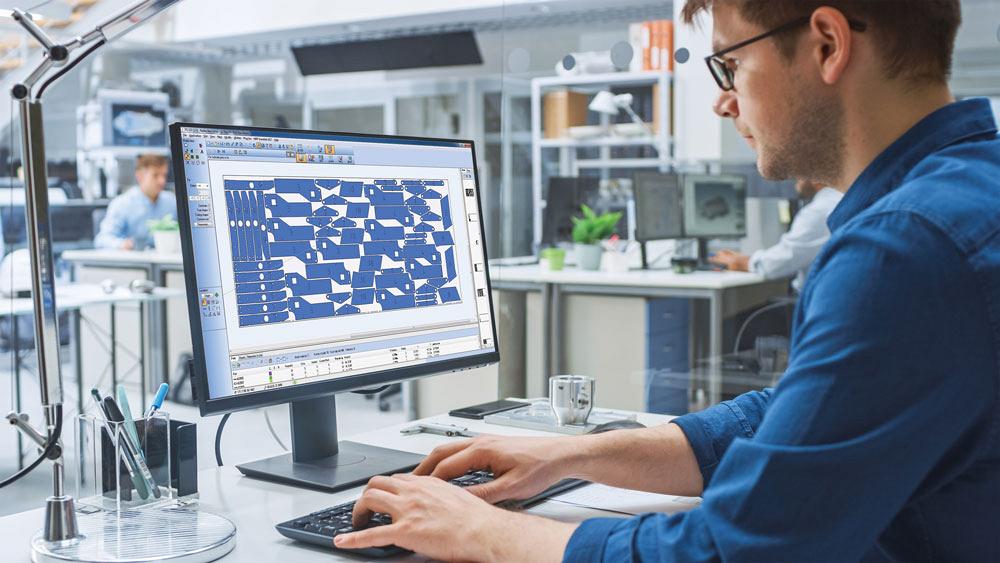

- Automation and Software

In today’s manufacturing market, many fabricators are shifting away from a traditional production environment and moving toward just-in-time manufacturing, where they make parts as needed rather than producing a lot of stock in advance. Fabricators are turning to advanced nesting software to meet these ever-changing demands and increase profitability.

Nesting software is designed to be used on myriad fabrication equipment. As machines get faster and more intelligent, the software needs to keep up. For example, laser cutting technology is getting more sophisticated, and the machines are getting extremely fast. Taking advantage of these advancements falls onto the nesting software. It needs to be able to keep the machines busy by getting parts quickly from the design system, whether it’s a 2D file, 3D file, or an assembly; import the parts; and prepare them for nesting. This process should happen in conjunction with scheduling information, importing demand files from a business execution system (MRP or ERP) and matching them up with the part geometry to be nested. Software can quickly generate nests to keep the machines busy and efficient.

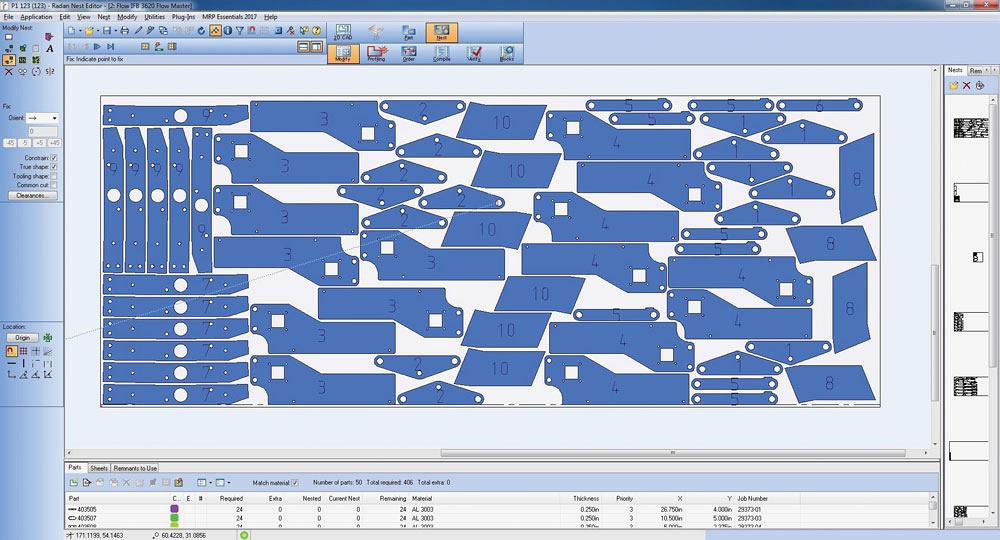

Historically, nesting engines looked at a list of parts and nested them on the first sheet, saved that nest, moved to the next sheet, and so on. Recent advancements in some software have enabled it to look at an entire batch of nests, meaning that the software starts nesting on the first sheet and continues nesting on subsequent sheets until the batch is fully nested. If it’s nesting on the fifth sheet and finds that it could remix the first two sheets to get better material utilization, it does that for the entire run of nests.

As technology continues to evolve, fabricators are finding more ways to leverage the software to boost their bottom line. Here are just a few ways they can take advantage of the benefits of nesting software.

Material Efficiency. Although each case is unique, true-shape nesting can have a significant impact on efficiency versus traditional grid nesting or single-part nesting. Often it can be difficult for programmers to keep up with the workload, forcing them to put out the immediate fire to get parts out the door instead of looking at the overall requirements. In this case, the programmer would have to produce single-part nests or grid nests. Nesting allows the programmer to add a series of parts to the schedule or nest project and the software will do the work. It will sort by material type and thickness to produce all parts in the schedule and potentially create remnants for future jobs when necessary. Fabricators can increase material utilization by 20 per cent or more by implementing a nesting system, depending on the range of parts they are nesting.

Today’s nesting software can nest in-part cutouts and part apertures to minimize scrap and, in some cases, reduce the clamp strip required by nesting around the clamps. Some software offers machine-specific nesting, which allows control of the part spacing based on tooling requirements either for a laser or a punch press, minimizing the web required between parts based on the machine’s capabilities. Additionally, nesting software can be set to look at a range of sheet sizes to determine the best sheet size to order for a particular run of nests to achieve the best material utilization.

Material utilization percentage is determined by the types of parts nested. Ultimately, a fabricator will identify several parts for the nesting software. In some cases, the mix of parts will not achieve the material utilization the fabricator is looking for. In this case, being able to mix jobs or expand the quantity of parts nesting can work with may be an option. However, this can come with its own set of challenges. For instance, a mix of parts that is too large can create logistical challenges to sort as they are coming off the machine. This could hold up secondary operations, and it could become a nightmare to sort the parts once they have been cut.

Nesting software has some features to help with these challenges, such as grouping parts together based on priorities and due dates. Once a part has been added to a nest, the software nests the required quantities without sacrificing material utilization. In some cases, fabricators can update the settings to include a parameter, such as finish the part required as long as 85 per cent material utilization is achieved.

Additional options are available with nesting software to help identify parts as they are coming off the machine. Depending on the machine tool being used, fabricators may be able to etch part numbers or critical manufacturing information on the parts as they are being cut. Several options are available for punching applications as well that offer the ability to stamp or inscribe the part. With some options, part numbers or other required manufacturing information can be added automatically, passing this information from the MRP or ERP system.

Increased Productivity. In many cases, software can add cutting information as the parts are being nested, removing the requirement to program the individual part. This speeds the process and helps achieve optimal cutting path efficiency by being able to add the lead-ins and lead-outs as the parts are being nested in a very logical location. This also ensures the machine is travelling the shortest distance between parts to cut and not adding additional travel on the sheet. Having a logical toolpath also helps to reduce the potential to collide with a tip. Nesting software can apply additional constraints to the toolpath logic, called feature avoidance, to ensure the laser will not collide with a tipped part or a punch will not collide with a form feature punched out on a nest.

Fabricators can increase material utilization by 20 per cent or more by implementing nesting software, depending on the range of parts they are nesting.

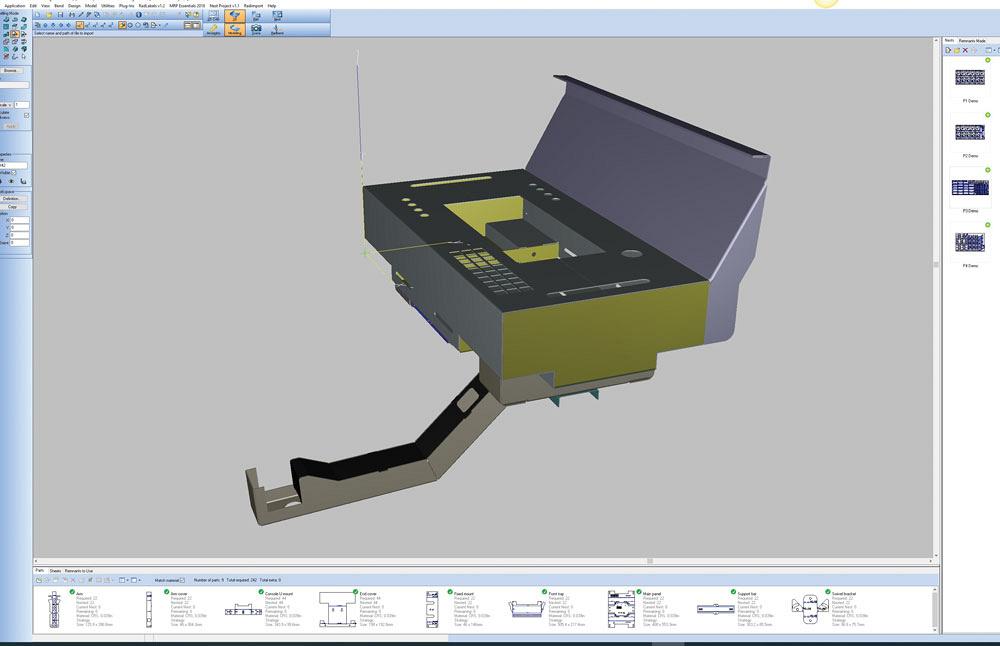

Nesting software can provide the necessary tools to integrate with design systems to process geometry automatically. Fabricators can import a series of flat DXF or DWG files and apply "cleanup" utilities to remove extra features and potentially close gaps in geometry. They also can process 3D files or assemblies, create flat patterns on-the-fly, and drop the parts into a nest schedule. Importing a bill of material to determine part quantities and applying a multiplier (such as "I need to produce 20 of this assembly") allows the fabricator to get the parts into the system and turn them into components that can be manufactured quickly.

Remnants. It’s rare to have the ultimate mix of parts to completely fill a sheet or series of sheets, which leaves the fabricator to deal with the left-over material, or remnants. To avoid this, one option is to expand the criteria, looking at a bigger window of parts. With this option, fabricators can regenerate a nest or a series of nests with the additional parts required to achieve greater material utilization. "Filler parts" also can be incorporated, such as brackets, flanges, and washers, that traditionally would have been cut out as a full-sheet program. The filler parts are added to the schedule and set accordingly. The nesting software fills in these parts when there is room on a nest, but will not start a separate sheet to produce them.

Remnants also can be created during the nesting process, with some software giving fabricators the option to automatically crop the sheet to create the remnant. These can be rectangular pieces, L-shaped pieces, or the actual skeleton pulled off the machine. "Ideal remnant size" is also a feature with some nesting software. Ideal remnant size allows the fabricator to input fixed dimensions or increments to crop the sheet, such as 6 or 10 inches; this will give logical remnant sizes for future jobs.

Data Management. Data is a critical part of the entire manufacturing process. Successful nesting software should be able to effectively interact with the business execution system (MRP and ERP) to receive information about which parts need to be cut and when they’re due. Data management also closes the loop by feeding information back to the MRP or ERP system about the material utilization achieved, how many sheets were required, and the total run-time, allowing fabricators to factor that into the overall cost. Integration of nesting software with a business execution system allows fabricators to stay on top of material needs in real time and order only the materials that are expected to be depleted from stock in the near future.

Doug Wood is general manager, RADAN Americas, production software, Hexagon Manufacturing Intelligence, 25 N. Lake St., Suite 220, Forest Lake, Minn. 55025, 800-875-7232, www.radan.com.

About the Author

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Aluminum MIG welding wire upgraded with a proprietary and patented surface treatment technology

Hypertherm Associates partners with Rapyuta Robotics

Protected and productive: welding helmet tech

HGG Profiling Equipment BV names Western Canada area sales manager

Compact weld camera monitors TIG, plasma processes

- Industry Events

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada