Editor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Analytics and adapting at Gullco

How this welding and cutting automation company keeps in step with its customers

- By Rob Colman

- November 30, 2020

- Article

- Automation and Software

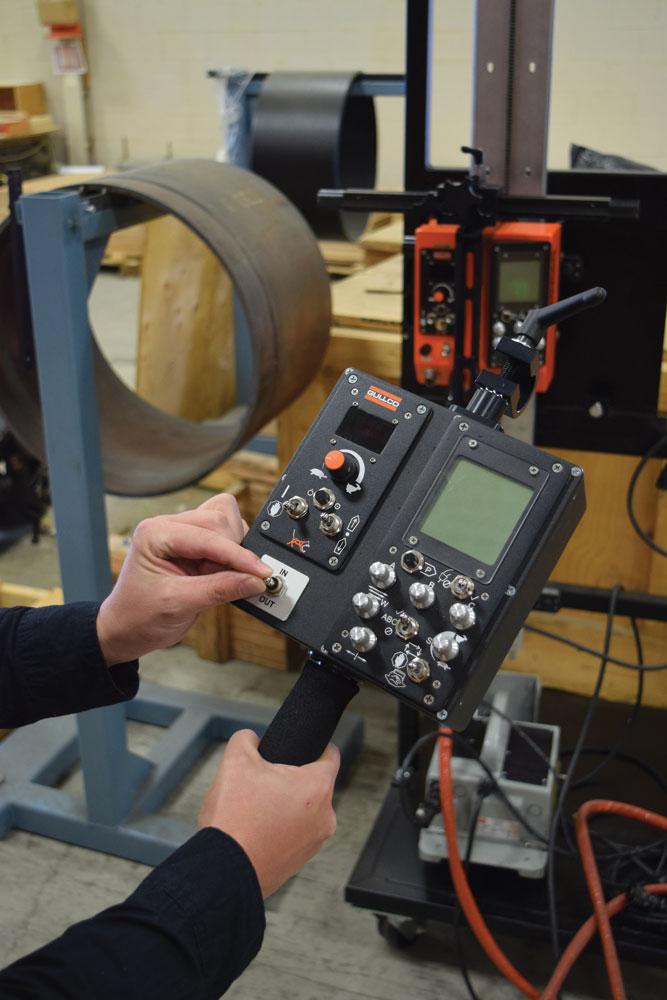

Gullco has upgraded its KAT 300 remote control to give users greater control of the arc. The remote control has been fine-tuned to allow the user to move the torch up and down and in and out.

Gullco International has been manufacturing welding and cutting automation equipment in Canada since 1954, and its headquarters have been in Newmarket, Ont., for 20 years now. While the backbone of its success has been its welding and cutting automation carriages (its KAT and MOGGY brands) and its bevelling equipment, the true value for many customers has been how the company adapts its standard components to customized needs. The ability to do so efficiently is made possible by a lean management structure and the adoption of an enterprise resource planning (ERP) system that Gullco is gradually rolling out to its operations worldwide.

The KAT 300

Gullco doesn’t often release new products. That made the launch of its 300 series KAT three years ago all the more noteworthy. In some ways the new KAT is similar to the old one – the drive system is very much the sameand the carriage is still aluminum. Differences are that the new drive has a smaller and lighter motor and the size of the carriage frame has been reduced significantly. Also, the new aluminum carriage is not cast as many of Gullco’s products are, making it possible to manufacture it in-house. The design has been tweaked to lighten the structure, including the creation of a dovetail racking system integrated into the carriage’s handle.

Previously a rack box riser was placed on the front of the carriage to provide the height necessary for vertical and horizontal adjustments in most applications. Now with the dovetailed handle, the carriage does not need the riser because the handle provides an adjustable mounting structure for the welding and cutting equipment.

Setup of the machine is also toolless now; everything can be locked in and adjusted without additional tools. In addition, the wheels are snap-lock wheels, which means operators can get them set to run more quickly than they could before.

On the technology side, the system has been designed with a conformal coating on the circuit boards to prevent them from overheating or being affected by dirt, dust, debris, and moisture.

All told, the new carriage weighs in at 13 lbs., which makes it more energy-efficient as well as easier for operators to manipulate.

Upgrades and Partnerships

Although this was a leap forward for Gullco, the company’s engineering team has continued to tweak the product based on feedback from customers.

“The base level carriage is still the same, and the durability is still there,” said Marketing Manager Nick Drake. “However, we’ve upgraded our remote control to give users greater control of the arc. The remote control has been fine-tuned to allow the user to move the torch up and down and in and out. These are the kinds of upgrades we are looking for regularly to ensure our customers can be as agile with our product as they need to be.”

Other market forces have driven Gullco to create partnerships to ensure the company has the tools customers are looking for on-hand. Most of these tools involve efforts to keep welders as far as possible from the weld arc and ensure their work area is as hazard-free as possible.

“In the U.K. now, for instance, you have to have at-source fume extraction,” said Drake. “We have partnered with Translas to make that technology available to all our clients. We now serve as a global distributor of the company’s fume extraction systems, which includes the 7XE semi-automatic welding gun with integrated fume extraction.”

Gullco has also worked with Canadian weld camera company Xiris on developing custom automation solutions with camera systems that can be included in its products.

“Between a lack of manpower available and new health and safety requirements being adopted in many jurisdictions, the value of an automated or semi-automated weld tool is becoming abundantly apparent to many companies that may not have considered it before. We are doing everything we can to ensure when a customer comes to us, we can put together a unit that meets all their specific requirements.”

ERP Agility

Much of the adaptability Gullco has established among its customers is due to the its lean manufacturing approach, which in turn has been enhanced by the adoption of a new ERP system at its headquarters in 2014.

“Gullco was originally operating with two separate focuses, one sales-oriented and one focused on manufacturing,” said Drake. “When we merged both organizations, it was an ideal time to upgrade our ERP system. And we achieved time and cost savings right away, in part because functions that were being duplicated by the two companies were now streamlined in one organization. But it also gave us better visibility on the shop floor, and orders could be moved from the front office to production much more quickly.

“I think of our product in similar terms as LEGO,” Drake continued. “All the pieces we make are modular, and they can be configured as the customer wants them to be. The key point in that is that we don’t keep a stock of ready-made carriages in our facility. As orders come in, we build them as requested by the customer. Before we had our ERP system, we could build a custom carriage in two to three weeks, depending on what the client required. Now we can build it in a day.”

Gullco used Epicor’s ERP software, but Drake appreciates that the right ERP system for his company may not be the ideal fit for another shop.

“We knew it would be useful for tracking our manufacturing processes,” he said. “Others might go for a system that’s more CRM- or marketing-focused, but this worked for us.”

Drake is keen on the analytics and sales trends he is able to observe through the system.

“We can gauge where the company is going and what our true competitive advantage is when it comes to products that span across every country we work in,” he said. “For instance, we sell 90 per cent of our welding ovens in Canada, but that shouldn’t be the case. Why is that? Having that data allows us to see that information easily, and we can then act on it.”

Since the rollout of the ERP system in Canada, Gullco has gradually been expanding its use to its other offices worldwide. It has already been rolled out in the U.S. and U.K., and Drake is in the process of introducing it to the company’s office in India.

“It is allowing us to take some of the ordering processing tasks in-house here in Canada, simplifying operations in other countries and keeping our focus on sales there,” said Drake. “Being able to manage inventory centrally is also helpful at a time like the one we’re experiencing in the pandemic. The central monitoring of inventory levels allows us to keep them where they need to be at all times.”

At the same time as these software upgrades have continued, the shop floor has developed further as well.

“We have added CNC machines to our shop floor to allow for the machining of larger parts without refixturing,” said Drake. “The more we can do in our own shop without depending on other suppliers, the faster we can respond to customer needs.”

The key to success today, in Drake’s mind, is being able to adapt continually.

“We are now used to updating our computers and operating systems every five or six years,” he said. “As the saying goes, the only constant is change, and change comes more rapidly all the time. Our goal is to always be on top of that, for our operations and those of our customers.”

Editor Robert Colman can be reached at rcolman@canadianfabweld.com.

About the Author

Rob Colman

1154 Warden Avenue

Toronto, M1R 0A1 Canada

905-235-0471

Robert Colman has worked as a writer and editor for more than 25 years, covering the needs of a variety of trades. He has been dedicated to the metalworking industry for the past 13 years, serving as editor for Metalworking Production & Purchasing (MP&P) and, since January 2016, the editor of Canadian Fabricating & Welding. He graduated with a B.A. degree from McGill University and a Master’s degree from UBC.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Aluminum MIG welding wire upgraded with a proprietary and patented surface treatment technology

Achieving success with mechanized plasma cutting

Hypertherm Associates partners with Rapyuta Robotics

Gema welcomes controller

Brushless copper tubing cutter adjusts to ODs up to 2-1/8 in.

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI