- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Tooling Goes Digital

Data-driven manufacturing takes another step forward with ISO 13399

- July 18, 2015

- Article

- Management

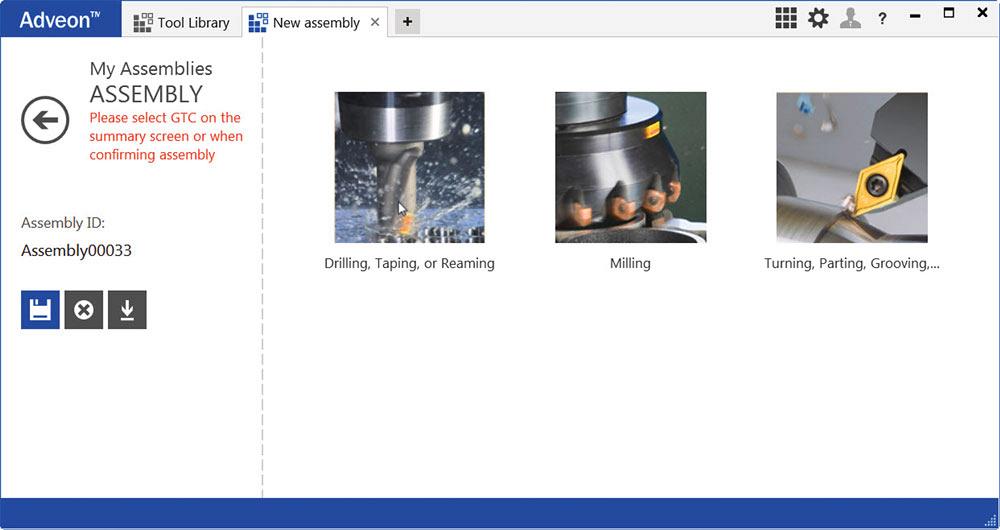

The Adveon tool library simplifies the tool selection process and also the building of tool assemblies. Image courtesy of Adveon.

Cutting tools can be the lifeblood of a shop; without them, production grinds to a stop. And, the decisions made about what tools to use in any given operation are among the most important and most debated calls made in modern shops. There literally are thousands of choices from dozens of manufacturers, and in today’s digitized world, the information is piling up.

ISO 13399 is a set of international standards enabling multiple tool manufacturers to use the same terms to reference their products—a single set of common identifiers designed to make it easier for software platforms such as CAM systems and simulation tools to work together. Currently the standard has definitions and abbreviations for more than 400 terms related to cutting tools.

CIM—Canadian Industrial Machinery asked Swapnil Gupta, virtual machining specialist for Sandvik Coromant, to describe how ISO 13399 can affect the way manufacturers select, build, and simulate tools. Here is what he had to say.

CIM: What led to the development of ISO 13399?

Gupta: The world is becoming more and more computerized with each passing year; this means that more and more information is available. In the cutting tool world, each manufacturer previously had been defining a tool’s attributes in different ways. Diameter, for example, could be called D by one supplier and Dx by another. It made life difficult and confusing for people using tools from multiple suppliers.

ISO 13399 eliminates that inconsistency. Tool dimensions can now be reported using the same definitions regardless of manufacturer, which eliminates this confusion.

CIM: What is the history of the standard?

Gupta: The development of the standard started about 15 years ago. We saw that in the future there would come a time when paper catalogs would be obsolete, but the need for tool information would still be extremely important. What we needed was a standard way of communicating that data to make it easier to transfer among computerized systems.

Like any other standard, it also is brand-neutral; it doesn’t support or favor any specific brand. This journey may have started 15 years as a collaboration among Sandvik Coromant, the Royal Institute of Technology in Sweden, and a few customers, but today many of the major tooling manufacturers are getting involved.

In the Sandvik group of companies, Walter, Seco, and Dormer are involved, and there are other companies involved like Iscar, Kennametal, and Mitsubishi that are coming onboard.

Sandvik Coromant may have spearheaded the project, bringing in different players from different industries, but the creation and adoption of the standard is larger than a single company.

CIM: What are the benefits?

Gupta: By having a system that defines attributes in a standard way, you ensure different systems can better communicate with each other, saving time and effort at programming and simulation stages.

CIM: How has the digitization of information affected the standards?

Gupta: We envision the future of manufacturing as a worker sitting at a computer controlling the shop floor. To make that happen, we need customers that have access to tool information without having to flip through catalogs and manually enter information.

One of the recent breakthroughs has been the Adveon™ tool library. This central brand-neutral tool library enables users to create and export tooling assemblies to CAM and simulation software packages.

The cutting tool data, which now adheres to the ISO 13399 standard, is easily accessible. This means that an open platform like Adveon allows you to work with tools from any supplier using the standard, ensuring the accuracy of all geometrical information.

CIM: Where will the time savings occur?

Gupta: It will change the way we look for tools and save time during that phase. It will save a lot of time and effort when programmers are trying to find tools from different brands. For example, if you are not currently using the ISO standard and you are looking for tools, you will likely look through many different catalogs. This can be a long process.

And if you are creating a tool assembly using parts from different suppliers, it can be difficult to know if they will fit together perfectly. That is more uncertainty that is now eliminated. The ISO standard will streamline that process, especially if the worker is new or doesn’t have a lot of tooling knowledge. Now the Adveon software will tell you which tools can be married together.

We feel that customers can save about 20 percent of the time needed for creating tool assemblies when they use the tool library.

CIM: What will it take for the standard to catch on at the shop level?

Gupta: When production managers and programmers learn about the standard and see the tool library being used, they see value right away. If you look at the CAM sector today, there is no full tool library in the market. That was a reason there was no standard. Once the standard was established it made a single, central tool library possible.

Before now the CAM systems didn’t have very well established tool libraries. They may have had a built-in library of a few hundred tools, but if you look at just Sandvik Coromant, we have more than 50,000 tools. And that is just one brand and a huge amount of data.

CIM: Can the standard adapt as tools get more complex?

Gupta: Absolutely. Like many other standards, this one is evolving as technology evolves. The standard will also evolve over time as manufacturers develop new tooling technology. As new tools are invented, we will provide the information about that tool to the standard’s governing body, and they will update the standard.

CIM: Where can companies get the tool library?

Gupta: It’s an add-on to CAM software and can be obtained from many of the CAM suppliers.

CIM: How does this affect the simulation stage?

Gupta: Before Adveon, the CAM system’s tool library needed manually entered tool parameters. This took time and also made errors possible during the data entry. Today the information is preloaded into the tool library.

There also is an on-screen benefit for designers and programmers. If you select a drill in the CAM package, for example, it typically just looks like a needle; it’s a very generic representation of the tool. With the tool library and this ISO standard, we are providing models of tools that are exactly the dimension of the tool. That changes the whole picture from a generic tool where every drill looks exactly the same, to providing the actual model of the tool.

In the simulation environment, you can now be much more comfortable using the tool on the machine after you are done with simulation.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI