- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Rotary Broaching: The Hole Thing Takes Shape

Solving unique manufacturing problems with rotary broaching

- By Jeff Tryles

- July 31, 2014

- Article

- Management

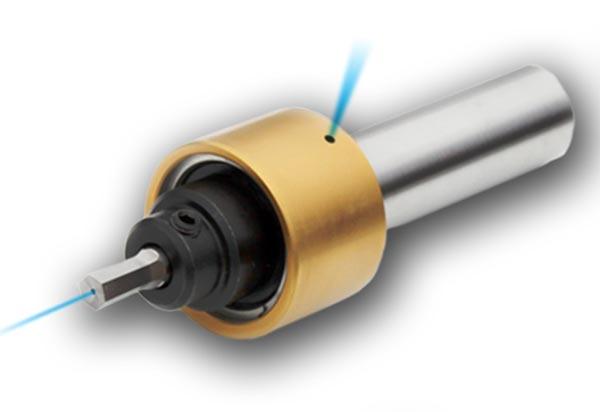

Rotary broaching cuts shapes into or onto a workpiece using a broach tool ground to the finished form, a rotary broaching toolholder, and either a lathe or mill. Photo courtesy of Slater Tools.

When they hear the term broaching, most people think of conventional step broaching, which involves pushing or pulling a toothed bar through a part on a press—a method that has been around since the beginning of (manufacturing) time.

The problem with conventional broaching is that it has application limitations and cost/efficiency drawbacks. For example, conventional broaches can be used only in through-hole applications. Also, it must be performed as a secondary operation on a press.

Costs and manufacturing leadtimes for conventional step broaches can be high. A newer manufacturing method called rotary broaching addresses these problems and can outperform conventional broaching in these areas.

Rotary broaching is a rapid machining method that cuts shapes into or onto a workpiece. It involves using a broach, which is ground to the finished form, and a rotary broaching toolholder on a lathe or mill. One advantage of the rotary broaching process is that it can be used in blind or through-hole applications.

Because this process can be used on any CNC lathe or mill, it can be performed at the same time as other turning or machining operations, so downtime for changing machines is eliminated. Additionally, the cost of a rotary broach is a fraction of the cost of a conventional broach with minimal to no lead-time.

Examining the Toolholder

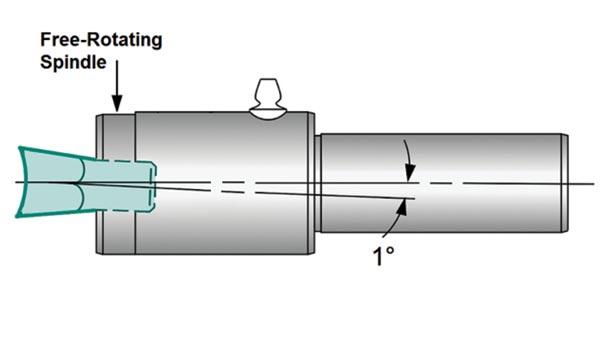

The rotary broaching toolholder has a free-rotating spindle on the front end, which holds the broach at a 1-degree angle (see Figure 1). The broach is driven by the workpiece so no live tooling is needed.

In a lathe, upon contact with the workpiece, the broach and toolholder spindle begin to rotate 1:1 with the workpiece while the body of the tool- holder is held stationary. In a mill, the workpiece is stationary, so the broach and toolholder spindle remain stationary while the toolholder body rotates in the machine’s spindle.

The 1-degree angle that is built into the toolholder allows the broach to have only one point of engagement at a time. With just one point of contact cutting at a time, very little thrust is required from the machine, which makes broaching possible on virtually any lathe or mill. The whole process can be completed in about the same amount of time as a drill cycle, and it creates a form within 0.0005-in. tolerance.

Any shop that has a CNC machine can perform rotary broaching, whether for machining a form into a blind or through-hole or cutting an external shape onto a part. Manufacturers utilizing rotary broaching have been able to bring broaching back in-house and drastically cut machining times and costs. In fact, many manufacturers are altering their machining methods to this technology from other, more costly methods, such as milling, EDM wire cutting, or knurling.

Figure 1

The 1-degree angle in the toolholder allows the broach to have only one point of engagement at a time, which requires very little thrust from the machine. Image courtesy of Slater Tools.

Some of the industries currently using rotary broaching are manufacturers of aerospace fasteners, medical implants, plumbing fixtures, and automotive parts.

While it has many advantages, there also are some boundaries to rotary broaching. For instance, forms larger than 2 in. are not recommended for this process. Additionally, for applications involving a broaching depth in excess of 1 in., rotary broaching can be difficult. For these types of applications, conventional broaching may be a better option. Small forms at shallow depths is the motto to remember with rotary broaching.

A multitude of materials can be successfully rotary broached, including alloy steel, brass, aluminum, stainless steel, titanium, and even plastics.

5 Questions—Broaching the Subject

CIM—Canadian Industrial Machinery asked Peter Bagwell, product engineer for Polygon Solutions, to discuss the ins and outs of rotary broaching. Here is what he had to say.

1. What is the difference between rotary broaching and conventional broaching?

Bagwell: Conventional broaching, either by a broaching machine or smaller push broaches, works by slightly increasing the height of a cutting tool with multiple teeth until the full form is achieved. As a result, the depth of the cut increases as the operation progresses.

A rotary broaching tool has only one cutting surface, which matches the full form. This cutting edge is rotated in a helical motion as it is fed through the part, machining the entire form in one pass.

2. When should each technique be considered?

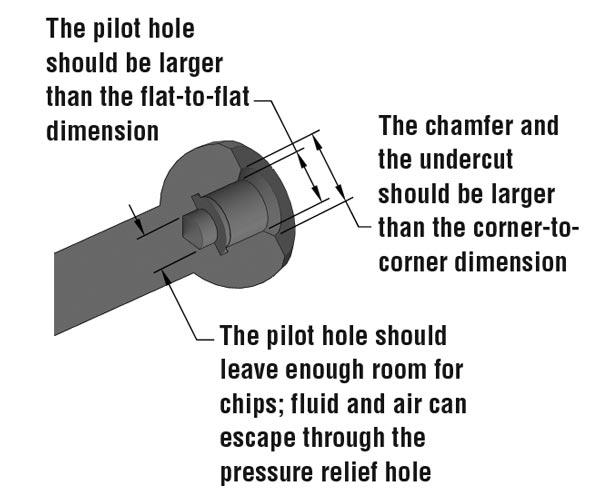

Bagwell: Conventional broaching generally requires paths that do not have obstructions and that do not have surfaces in multiple planes. Broaching to a shoulder is also not ideal. Broaching requires a pilot hole to get started. Parts to be broached must be supported and be strong enough to withstand the required thrust forces.

New technology such as pressure relief holes reduces thrust, enabling the broaching of blind holes. Image courtesy of Polygon Solutions.

Because the rotary broached form is limited to one pass, the amount of tool material to be removed is limited in width and depth. Rotary broaching is best considered for smaller machined forms where secondary operations can be eliminated.

3. What is the role of workholding in the broaching process?

Bagwell: Workholding is very important for on-machine broaching. The broaches must be in line with the pilot hole; the machine and the workholding must be able to withstand the broaching forces; and occasionally there is a desire to align the broaches with other features on the workpiece.

Rotary broaching does have some characteristics that reduce the need for extreme accuracy in the workholding. Most rotary broach toolholders have a small amount of endplay that helps if the work or broach is slightly off-center. Rotary broaching also requires the use of a chamfer to get the chip curling, and this chamfer helps center the broach.

Most challenges with workholding are the result of the forces required to complete the operation.

For example, if the form is large, the material is hardened, or if the pilot hole is too small, barstock may push back in a lathe. The best solution is to improve the pilot hole and try to reduce the required thrust. Optimized drilling will reduce the chip load and may remove work hardening or irregular machining.

Workholding for aligned or “clocked” forms depends on the machine used and the level of accuracy required. If a square hole needs to be aligned with a flat on the outside of a part, the ability of a lathe to be oncenter and repeat the zero position may be most critical. An alignment tool called a broach brake holds the broach orientation as it leaves the previous part. The next part needs to be presented in the exact same position.

However, if the part is made in a mill, fixtures made to hold the part will affect the accuracy. In a mill, the centering of the cutting tool is controlled by positioning the table. The fixtures must be strong enough and accurate enough to hold the part while broaching.

4. When is rotary broaching the best machining option?

Bagwell: Rotary broaching is a very fast technique for manufacturing small forms in precision machined products. Time and cost savings are possible for many reasons. The most outstanding savings come from eliminating secondary operations. Keeping the part on the same machine reduces transfer time, storage, setups, and various risk factors.

Manufacturers of aerospace fasteners, medical implants, plumbing fixtures, and automotive parts can use rotary broaching in the manufacturing process. Photo courtesy of Slater Tools.

Compared to conventional broaching, electrical discharge machining (EDM), or shaping, rotary broaching also has cost advantages. Cycle times for rotary broaching are very short compared to EDM. The cost of a rotary broach is a fraction of an EDM electrode and it can be shipped immediately from stock. Standard lathes, mills, and other turning machines are more readily available than broaching, EDM, and shaping machines.

5. How has this technology changed recently?

Bagwell: Recent innovations in rotary broach tools continue to make the process more attractive. Sealed toolholder bearings eliminate the need for operators to grease the unit every two hours. And pressure relief holes can reduce the thrust required to broach blind holes. Standard all-inone form drills reduce setup time and create a more lean production environment, and adjustment-free broach holders can be installed quickly and easily.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI