- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Design Is an Obsession

DNS Industries-manufactured displays entice shoppers across Canada

- By Sue Roberts

- February 4, 2015

- Article

- Made In Canada

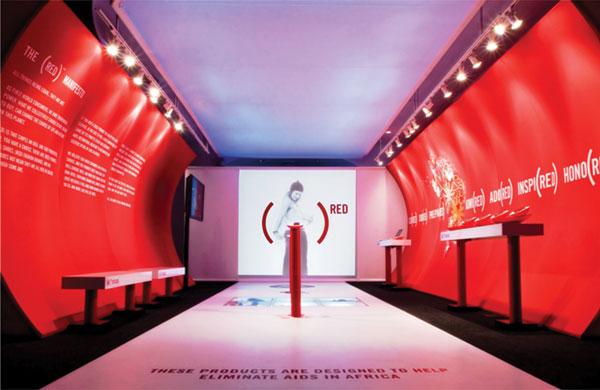

The National Association of Store Fixture Manufacturers honored DNS with a Pop-Up Store of the Year Award in 2007 for its flooring contribution to the Motorola (RED)™ project in Chicago. Products were displayed beneath Plexiglas panels. Photo courtesy of DNS Industries.

OCD (obsessive-compulsive disorder) is usually considered a problem. Change the initialism to stand for obsessivecompulsive design and it can be a behavior that is coveted by companies selling products in the consumer world.

DNS Industries, Concord, Ont., proudly touts how that obsessivecompulsive design is a company affliction and how its tendencies surface when creating and manufacturing fixtures and displays for retail outlets.

“Our design engineering is one of our strengths,” said Mike Douglas, president. “We put much thought into the front end of a design so it meets every specification, flows seamlessly through production, and looks right for its floor life. That’s where our OCD comes into play. We’re obsessive- compulsive about designing products that last. You see some displays in stores that are held together with tape—they just don’t perform like ours.”

Partnering With Name Brands

“We’re a full-service manufacturer that is a bit unique in our industry because we build both fixtures and displays,” he added. “Usually a company will do one or the other, but we offer both and can coordinate designs.”

Wood, plastic, and metal components come together in the 20,000-sq.-ft. shop to create freestanding displays that typically have a lifespan from 12 months to three years and fixtures like cash desks and backwall racks that are more permanent. The displays are promotional and designed to entice shoppers to pause and examine products. The fixtures need to be durable, attractive, and comfortable for store personnel and customer use. Both have to be resilient to stand up to what can be rough handling in a retail environment.

Tim Hortons®, DeWALT®, adidas®, Coca-Cola®, Nokia®, and Energizer® are just a smattering of the wellknown brands that have promoted products on DNS-built displays. Freestanding units have showcased home improvement tools in big-box stores; countertop and drive-through boxes have collected coins for charity; and high-end running shoes have been positioned for 360 degrees of viewing. Some items are secured to the displays, and some displays themselves are attached to physical structures. Some incorporate electronics to give the customer an interactive experience. Each is custom-designed.

A unique floor comprising brightly lit product below Plexiglas® panels exhibited the company’s fixturing ingenuity and earned it the 2007 Pop- Up Store of the Year Grand Prize Award from Chain Store Age. The floor was installed in a Motorola® (RED)™ outlet in Chicago. As part of the RED project, initiated by musician and humanitarian Bono, several major brands opened temporary locations using the color red as a unifying theme and donated some of the profits from store sales to help eliminate AIDS in Africa.

“We were asked to be part of the team that turned a store into the RED look for a temporary situation,” Douglas said. “So we put this concept together, manufactured the components, and got it installed in about two weeks. There were a lot of sketches made on airplanes by designers and faxed from hotels to move the project quickly, but it came together really well. We finished the day before Oprah and her crew arrived to film a promotion for the project.”

Home Depot® brought a different kind of challenge to the company: Design a fixture to display hand tools from multiple companies and make it rugged enough to withstand bangs from carts and run-ins from forklifts.

A wall filled with point-of-purchase counter displays manufactured at DNS Industries stretches behind Mike Douglas, company president.

“We had to work with three different manufacturers and Home Depot. We had to be sure everyone’s branding was correct. DeWALT®, Makita®, Milwaukee®, and the retailer had to sign off on every aspect of the design,” Douglas said. “But we had complete license as far as how it was going to be built. We incorporated different features to be sure it would look pristine after experiencing on-floor abuse. For example, we added tread plate around the bottom. If we had used the usual painted skirt, it would have been scuffed up in no time.”

Poised for Expansion

Canadian shoppers see about 70 percent of DNS displays with the other 30 percent luring U.S. consumers’ dollars. “Many retail head offices that we work with are located in Toronto to handle Canadian rollouts. A lot of the designs for U.S. consumers don’t fit our Canadian market, so companies look for a local company to design something that will work here,” Douglas said.

Design nuances are based on two key market differences: The Canadian retailer typically aims for more sales per square foot, and Canadian shoppers exhibit more brand loyalty.

The company opened its doors in 2001 when Douglas left another display firm to start his own. “We started on a shoestring providing services mostly for existing clients and agents that I had long-term relationships with. We survived off of word-of-mouth. As things started to improve after the 2007 recession, we took a more active role in marketing the company. We saw the need to become more sales-focused. We knew how to manufacture, and we were ready to do more.”

That’s when Daniel Robert joined the company as partner and CEO. Robert’s marketing expertise is driving the effort to do more work directly with end users. “We still have traditional relationships and work with marketing firms, but we’re also reaching out to potential customers in a very direct way,” said Douglas.

Plans are in place to secure contracts for more fixtures and displays in U.S. stores. “Whereas the U.S. companies often don’t want to create products for the smaller Canadian market, we can take care of Canada and adapt our designs to the U.S. requirements,” Douglas said.

New markets are also part of expansion plans. Growth in fixtures, displays, signage, and products for the hospitality industry is on the radar.

It Starts With One

Every order starts with a quantity of one. On the store fixturing side of the business, Douglas said quantities are “usually one of this and one of that.” On the display side, a Canadian national product rollout averages somewhere between 100 and 200 units.

Assembly of units in quantities from one to thousands is a key process in the DNS shop. Photo courtesy of DNS Industries.

For the multiunit display orders, the first display produced is a prototype. Its concept could be created wholly by DNS or based on a customer’s idea with fine-tuning and engineering done in-house. Customer-driven designs typically come in with basic drawings but without the details needed to bring the project to production.

“There are always refinements after the prototype,” Douglas said. “But we get the structure of the prototypes as close to perfect as possible so it isn’t necessary to revise or refine the engineering aspect of the display. We make sure that the components come together as anticipated and that the display will stand up to the customers’ requirements.”

Robert said, “Typically speaking, we are lucky to cover costs for the prototypes. It’s once we go to production, after we’ve refined the processes, that we make money. But without the prototype, we don’t get the rollout quantities.”

The quantity-of-one concept also holds true on the shop floor, where lean manufacturing processes are implemented in the one-piece flow. All resources are dedicated to a single product build until the order is complete.

“For our quantity orders, all steps occur simultaneously, so if we identify a problem with step one, during step two we can quickly go back, rejig step one, and keep production going without a loss,” Douglas said. “Another beauty of the one-flow approach is that we can quickly rejig our plant to shift to another product.”

On occasion a product becomes a shop regular. When this happens, the company takes advantage of the opportunity to tighten and improve production.

“With most of our custom projects, we rely on experience and instinct when we move to production. We build on what has worked in the past for similar projects, and we have the right team to adjust the process according to the nuances of the piece being built.

“A few products like the cash boxes for Tim Hortons repeat,” said Douglas. “The repeats let us refine production processes. Every time we’ve put that project on the shop floor, we’ve gotten a little better.” Order quantities for the Tim Hortons products can be as high as 8,000 units.

Expanding Manufacturing

In-house capabilities are expanding along with marketing efforts. “We are bringing in new equipment and expanding our capabilities,” said Douglas. A CNC router and waterjet table have joined the saws, planers, buffers, and heat benders. An additional seat with SolidWorks® helps engineering keep designs flowing.

Adding a vacuum lifter to load materials on the routing table turned a two-man job into a one-man job and increased productivity.

A Kaitian® laser/engraver produces acrylic parts that go directly to assembly. “When we were using the router it took three steps—route the part, hand-clean it to remove chips, and then flame-polish,” said Robert. “The laser reduces that process to one step, improving productivity. It also increased our material yield. The kerf is reduced and we have less scrap.”

The MultiCam® 5000 series router fabricates parts from sheets of MDF (medium-density fiberboard), melamine, aluminum, and plastic. A new Schmalz® vacuum tube lifter loads the material. Robert said, “Loading a sheet was a two-person job that is a one-man operation with the lifter. Think of the time it takes someone to stop what they are doing, walk 30 feet to help load a sheet, and walk back to their own job. We save labor with the lifter, and it’s safer for our operators.”

Exotic plastics that can’t be routed and some ferrous parts are cut on a MultiCam 3000 series waterjet table, also a new addition to the shop.

The company is positioned for growth. “We put our attention to getting it right. We bring something special to the table with our established customers and our new prospects,” Douglas said. “We have the right people who bring all the elements together to do the right things for a quality product.”

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI