- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Bearing Down on Manufacturing

J/E Bearing and Machine brings smalltown problem solving to big customers

- By Joe Thompson

- November 11, 2014

- Article

- Made In Canada

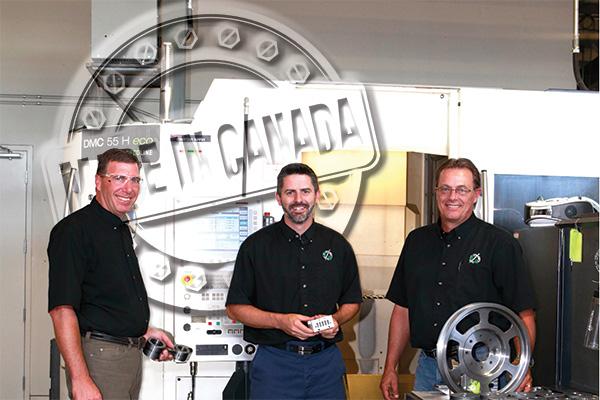

(l to r) Joe Volkaert, president; Derek Rozon, plant manager; and Chuck Hendricks, vice president of sales for J/E Bearing and Machine stand with parts created with the company’s latest CNC machining center.

Manufacturing happens all over this country. In big cities, on gravel roads, and everywhere in between.

Just past the train tracks in Tillsonburg, Ont., not all that far from some cornfields, sits J/E Bearing and Machine, a machine shop, custom manufacturer, and supplier of power transmission and bearing-related products.

J/E is a family business, proud of that fact, and has been since its founding in 1983.

Back then founders Joe Volkaert Sr. and son-in-law Chuck Hendricks ran the business from a strip mall, serving the area’s local farmers and industrial businesses. Unsurprisingly, a lot can change in 30 years. Today, while it continues its tradition of serving the local community, the company also deals with some of the biggest names in manufacturing, including General Dynamics Land Systems (GDLS) of nearby London, Ont.

Only five years after its formation, the company outgrew its strip mall location, which led it to purchase an open lot down the street and build an 8,000-sq.-ft. shop. Now totaling 25,000 sq. ft., the J/E building has been expanded twice to accommodate growth, particularly in the machine shop, where CNC machine tools are now the norm.

While the bearing and power transmission distribution side of the business still is important, ongoing growth in capacity and capability in the machine shop is helping the company compete in today’s manufacturing environment.

Growth Cycle

While J/E worked mainly with the automotive and aerospace sectors during its early years, a defense supply chain opportunity arose in 2000, and the company began to supply the U.S. military with ball joints for its Humvee military vehicle platform.

Creating -- and patenting -- the ball joint, the company now supplies these aftermarket products, which are designed to handle much more weight than the stock parts installed at the assembly plant. In 2007 the company received its first full U.S. military contract for the ball joints.

“It’s an interesting product for us,” explained Hendricks, who serves as the company’s vice president of sales. “It really combines all of our areas of expertise into one part. There are bearings, fairly complex machining of hard material, and design work all together. And in all the years that we’ve been doing them, we’ve never had a broken one come back.”

Founded in 1983, the company moved into its current location in 1988. Two expansions have added to the building’s size, primarily in the shop area.

It is this type of problem-solving and a desire to tackle more complex jobs that helped the company start to grow.

As more work came to the shop, so did new equipment. From 2006 to 2008 the company purchased three Doosan vertical machining centers and two Doosan lathes from Mississauga, Ont., machine tool distributor Ferro Technique.

It meant a lot of change for the company.

“The business today is almost unrecognizable when compared to where we started,” said Hendricks. “Serving the local area like we do, we used to have to wait for work to literally walk in the door. Now, while we still serve the area in much the same way, we also do work that is exported, and also some subcontract work for larger manufacturers.”

The Downturn

The 2009 recession, the boogeyman for many businesses, didn’t pass by J/E, however. But even as the economic downturn took away business, Hendricks and Joe Volkaert Jr., J/E Bearing’s president, put an emphasis on the family nature of the company.

“We probably waited too long to downsize during the recession,” said Hendricks. “We were bleeding red ink, but we thought we could survive it without losing anyone.”

In the end the company was forced to lay off staff.

“Those were hard conversations to have, but, looking back, I’m not sure we’d still be here if we hadn’t,” said Hendricks.

But the company did survive … and thrive.

Adopting Advanced Technology

Hendricks and Volkaert knew that if they were going to get the company back on track, they had to be profitable, and that meant being more productive. They also needed machine capacity, and with floor space already getting tight in the shop, they decided that a machine that could perform both turning and milling operations would solve this problem, while also providing other benefits.

Late in 2009, even as orders began to dwindle, the company invested in its most advanced machine to date, a Doosan Puma TT2500SY multitasking machine.

“That machine gave us the ability to do short-run, high-variety work that was also very high quality,” said Hendricks.

Finally, as manufacturing work returned to the sector, some of the business that had vanished during the economic downturn was being replaced, and the new capability of the shop was one of the drivers. An investment in new technology, in combination with the expertise of the staff they had in place, was reducing cycle times, eliminating rework, and allowing the company to once again be profitable.

The shop’s latest addition, a DMG DMC 55 H eco horizontal machining center, recently was installed to add even more capability to the floor.

“It was a pretty easy decision,” said Hendricks. “We had parts that we needed to make that would have been impossible to create on our vertical machines.”

As one example of the work that is now possible thanks to the addition of the HMC, Hendricks pointed to a part that begins the production cycle as a 70-lb. block of steel and ends up weighing only 18 lbs. It’s part of a new strategy at J/E. Short-run, high-value parts that can be produced in tight timeframes with tight tolerances are the new normal.

One of the reasons for this new way in thinking can be traced to a 2013 contract the company was awarded by GDLS as part of that company’s contract with the Canadian Army for its Light Armoured Vehicle (LAV) III upgrade project.

J/E is manufacturing bearing assemblies that are critical components in the LAV III’s driveline.

J/E Bearing is a custom manufacturer and job shop serving primarily the industrial, automotive, aerospace, and defense sectors.

“When you start dealing with a company like GDLS, there are certain expectations that you have to fulfill,” said Hendricks. “They really helped drive home the fact that we needed our shop to be a little more cutting-edge. But, at the same time, we realized we could do the type of work they were asking for. They even liked the fact that we are a small, family-run business that enjoys the problem-solving nature of manufacturing. It’s been a great relationship for us.”

In between its humble beginnings and today has been growth, setbacks, and a companywide re-evaluation that has led them to question everything. In short, it’s been an evolution.

Company Evolution

“We recently took a long, hard look at every department, looking for inefficiencies,” explained Hendricks.

What they found were multiple areas that could be improved upon.

“Part of what we did was essentially install some lean principles and practices in the shop,” he said. “Eliminating waste, whether it’s wasted time and material on the floor or time wasted in the office in the billing cycle or ordering process, is good business. We knew we had to work smarter, not harder.”

For example, the company recently added a Matrix tool management system from Iscar Tools to help better manage its consumables. The system helps the company’s operators locate tooling and other consumables quickly, because they can see if the tool is in the crib or if another operator has it.

With multiple operators and many machines, the number of tools necessary to maintain productivity can become overwhelming. In the current business environment, every little bit helps, admitted Hendricks.

“We are not using the dispenser in a ‘Big Brother’ way to track all of the little details, but it certainly helps the guys when they are looking for a specific tool,” he said. “We no longer have guys wandering around the shop looking for one particular tool. It is taking some getting used to, but thankfully we have the right type of employees that realize we are trying to work in a more advanced way.”

The system also enables J/E to track tool usage and determine when tools should be ordered, eliminating the possibility of running out of a particular item.

Getting the company’s employees to buy in to what they are trying to accomplish was easy, said Hendricks.

“When you have the right people, and that’s what we think we have here, implementing change goes a little smoother,” he said. “Finding skilled labor is a little tricky in an area like Tillsonburg, and some of our guys travel an hour or more to get here. We don’t want to lose them, so we try to do as much as we can. It’s the way we started, it’s the way we’ve always run the business, and it will continue that way.”

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI