Application Engineer

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Submerged arc welding consumables selection

SAW flux and wire combinations require careful research to determine the optimal choice

Unlike GMAW, SMAW, and FCAW consumables, for which the classification required is easily determined and the product can be selected with minimal consideration, submerged arc welding (SAW) flux and wire combinations require a multiple-step process to determine the optimal choice.

Factors that must be considered include:

- Is this a single-pass or multipass application?

- What are the required Charpy V-notch (CVN) properties of the weld metal?

- Will the weldment be post-weld heat-treated? Time of stress relief?

- Is the weld a two-run or single-run weld?

- Is the weld for sour service applications?

Some welding consumable manufacturers have a comprehensive flux and wire portfolio. When you consider all the possible permutations and combinations of flux and wire, it may be possible your current combination is not optimal for your application.

Welding Electrode Selection

For a particular application, the AWS/CSA electrode classification is often dictated by the engineer of record, the particular welding code, or perhaps simply the need to match the base material chemistry.

A common example is an AWS E7018-1 or CSA E4918-1 SMAW electrode, or the AWS E71T-1 or CSA E491T1-C1A3-CS1 gas-shielded flux-cored electrodes.

SAW Flux Wire Classification

A SAW electrode normally has an AWS classification, which is determined by the electrode composition, so you can have an equivalent electrode. SAW flux alone cannot have an AWS/CSA classification, so there is no “equivalent flux.”

A SAW flux/wire combination, however, does have an AWS/CSA classification. You can have an equivalent flux/wire classification.

Caution must be used when you select a flux/wire solely by classification.

For purposes of discussion, open arc electrodes of similar classification will have comparable performance and mechanical properties. For example, different brand/trade name ER70S-6 and B-G 49A 3 C1 S6 GMAW wires generally can be used for the same application.

This is, however, not the case with SAW fluxes and wires.

For example, Lincoln Electric has more than eight flux and wire combinations that all meet the same F7A2-EM12K classification. The electrode in this example is the same (Lincolnweld L-61), but multiple fluxes yield this classification.

Unlike our example of the GMAW electrode, the performance of different combinations for SAW may vary tremendously, despite all having the same flux/wire classification.

Active or Neutral Flux

Active fluxes add a certain level of silicon (Si) and manganese (Mn) into the weld deposit.

Neutral fluxes, as the name implies, contribute relatively low amounts of Si and Mn.

A flux is deemed “active” or “neutral” depending on the Wall Neutrality Number. This number is determined by the flux manufacturers through a series of weld deposit chemistry tests.

WN# = 100 (|Δ|Si + |Δ|Mn)

As per AWS A5.17, a flux is deemed neutral if its WN# is equal to or lower than 35.

Why does this matter? It is generally accepted that an active flux should be used only for single-pass applications. The reason for this is that in multiple passes, the Mn content can increase to a level where strength and hardness levels become excessive. Elongation properties can also decrease. These conditions can lead to weld failure. This situation can be exacerbated by excessive voltage levels, since higher voltage can cause greater flux melt off into the weld.

Back to our example of AWS F7A2-EM12K / CSA F49A3-EM12K:

Lincolnweld 761/L- 61 has a high Wall Neutrality Number and is considered an active flux. It therefore excels, due to the relatively high deoxidizer content (Si/Mn), at welding over light contaminants such as rust and mill scale. This combination, however, is not a good choice for multiple pass heavy plate welds.

Lincolnweld 960/L-61 has the same classification of F7A2-EM12K as 761/L-61 but it is a neutral flux. This makes it a much better choice for multiple-pass welding. Performance on mill scale and other contaminants, however, will not be as good.

Whether the application is single or multiple pass is a critical factor in selecting a flux/wire combination.

Charpy V-Notch Requirement

The testing temperature of the impact properties (test temperature of CVN) can be seen in a flux wire classification.

AWS F7A2-EM12K denotes a -20-degree-F CVN test temperature.

A similar CSA F49A3-EM12K denotes a -30-degree-C CVN test temperature.

In selecting a flux/wire combination, consider the required CVN properties.

For example, if a pressure vessel application requires a CVN value of 20 ft.-lbs. at -60 degrees F as welded, we need to ensure that classification is at least an F7A6.

The commonly used Lincolnweld L-61 (EM12K) electrode yields classifications ranging from F7A0 (0 degrees F CVN) to F7A8 (-80 degrees F CVN). This is a significant range of toughness just by changing the flux it is paired with.

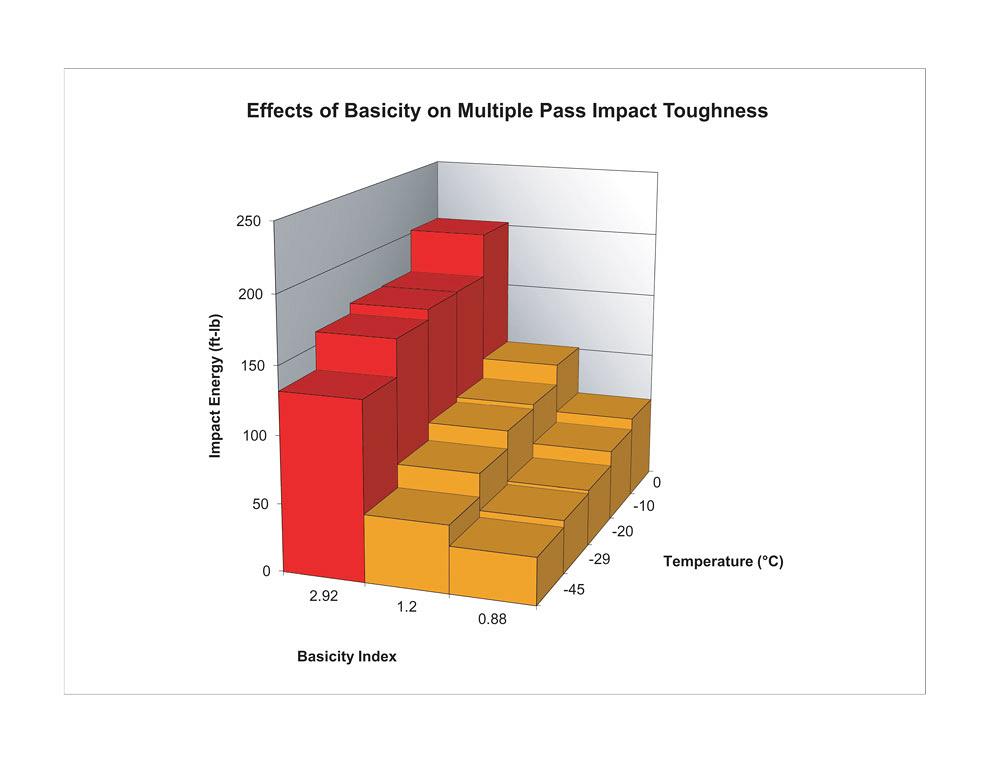

Flux Basicity

The flux basicity index (BI) is calculated using various formulas that quantify the ratio between basic and acidic components of the flux.

Lincoln Electric uses the Boniszewski basicity index formula:

BI = 0.5(FeO + MnO) + CaO + MgO + Na2O + K2O + CaF2 / SiO2 + 0.5(TiO2 + ZrO2 + Al2O3)

Generally, a higher BI yields a microstructure that is more conducive to robust CVN properties. The notable exception is single-pass or two-run welds.

Flux manufacturers typically publish the B.I. of their fluxes on the material datasheet.

It should be noted, however, that fluxes should not be chosen based solely on BI, nor should fluxes be cross-referenced based on this number.

Post-weld Heat Treat (PWHT)

Generally speaking, for a carbon steel weld deposit, the ultimate tensile strength (UTS) and yield strength (YS) will drop after PWHT.

This must also be taken into consideration when selecting flux/wire combinations since not all of them will meet the same strength level as welded and after stress relief.

The strength can be determined by the flux/wire classification. The A in the classification denotes the “as welded” condition, and the P denotes a PWHT condition.

Please note that typically PWHT results are for one hour at a specific temperature, usually 1,150 degrees F/650 degrees C. For longer hold times and higher temperatures, strength levels will be further reduced.

For example, the Lincolnweld 882/Lincolnweld LA-71 electrode classification is F7A6-EH11K/F7P6-EH11K. This indicates that this combination will meet the requirements for an F7, or 70-KSI UTS.

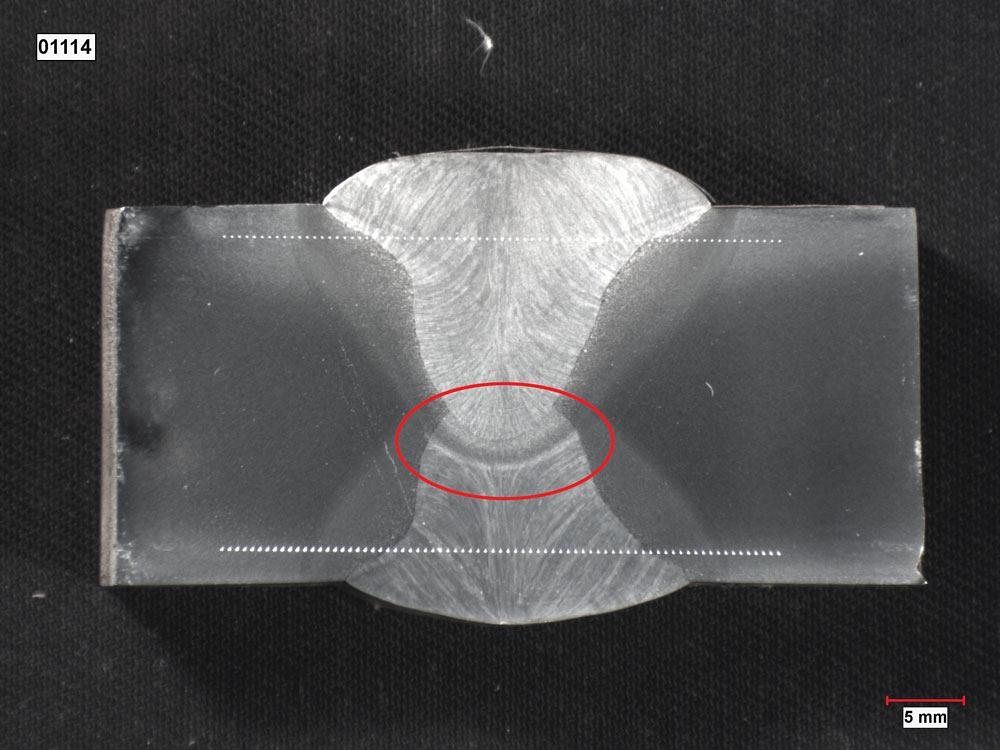

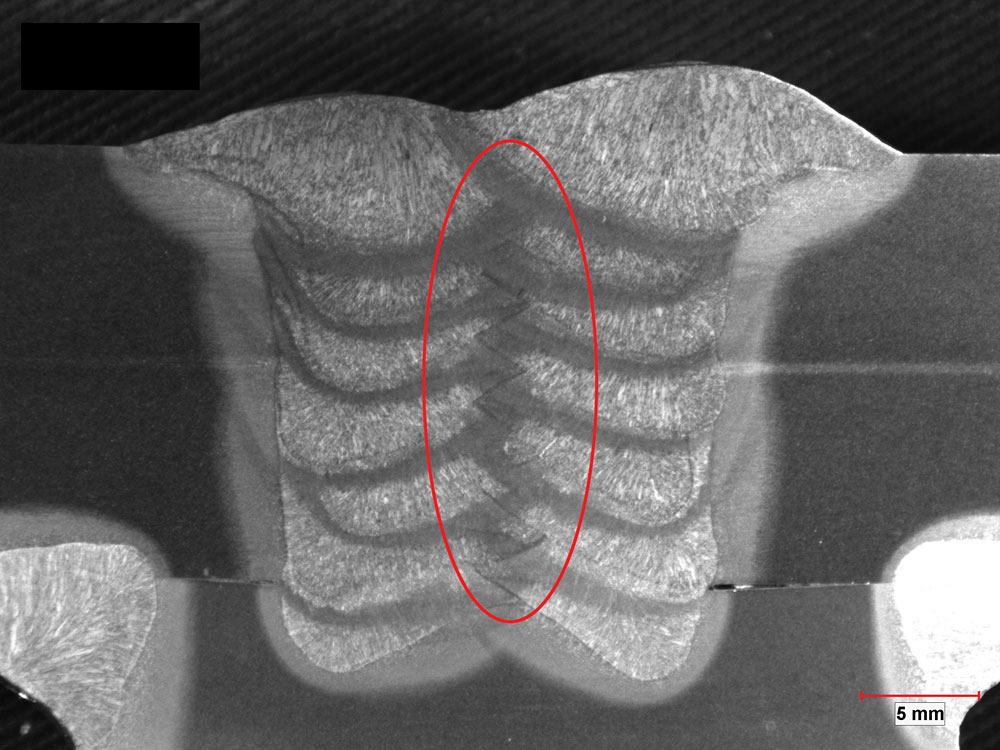

Two-run Versus Multi-run: Grain Refinement

Most classifications are determined with multiple-pass test plates as required by CSA and AWS.

Grain refinement from reheating occurs when a subsequent weld pass is made over a previous pass. This darker zone of finer grains can resist impact better than the coarse, unrefined grain structure.

As you can see in the photo (Figure 2), a two-run weld (one pass each side) has much less refined weld metal. As a result, the CVN properties of the two-run weld tend to be less robust than the multiple-pass weld. Furthermore, the base material dilution is typically much greater in a two-run weld.

Rule of Two-run Welds

Do not use multiple-pass test results (particularly impact toughness) to predict the performance of a flux/electrode combination in a two-run application, and vice versa.

AWS A5.23 Two-run Classification

Two-run welds are typically found in pipe mills, shipyard panel welding, and wind towers.

If your application is two-run or single-run, you should review if the combination has a two-run certificate of conformance (COC). Two-run COCs are denoted by the addition of the letter T after the strength designator.

For example, Lincolnweld WTX-TR flux with Lincolnweld L-61 has both a multi-run COC (F7A6-EM12K) and two-run (F7TA4-EM12K) COC.

Flux/wire combinations must be carefully selected for single- and two-run welds since the vast majority of flux/wire combinations in the market may not be suitable for this application.

NACE Sour Service Requirement

The National Association of Corrosion Engineers (NACE) MR 0175/ISO 15156 for Sour Service (H2S) limits the weld deposit to 1 per cent nickel (Ni). Not all Ni low-alloy electrodes will meet this limit.

Due to the complex nature of flux and wire selection, it is suggested that you engage your welding consumable manufacturer to discuss in detail your particular requirements.

Ken Mui, P.Eng. is application engineer, Lincoln Electric, ken_mui@lincolnelectric.com, www.lincolnelectric.com.

About the Author

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada