- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Tools for High-efficiency Milling

- July 26, 2015

- Product Release

- Management

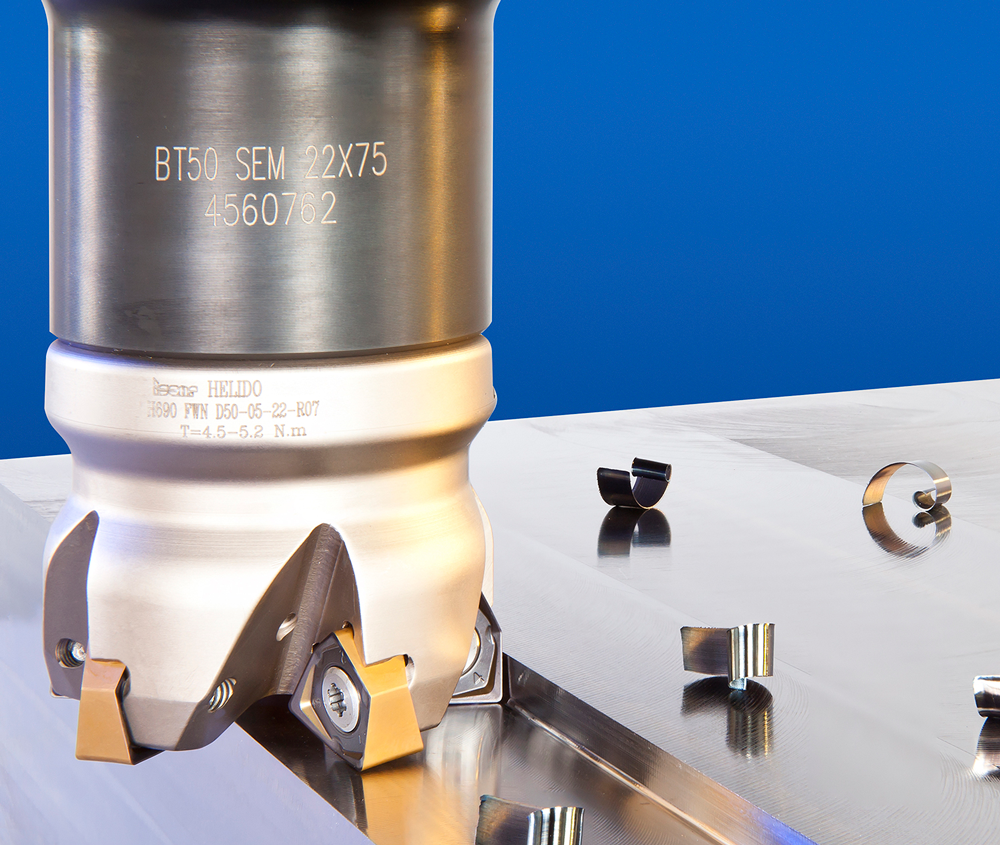

Iscar has introduced the Helido Trigon H690-07 line of tools for the roughing to semifinish milling of cast iron and steel components.

Each cutter body has coolant holes directed to the inserts’ cutting edges to provide the most efficient cooling action. These milling cutters have a 90-degree cutting edge angle and carry H690 WNMU 0705 trigonal double-sided inserts.

The inserts have six positive cutting edges which can be used for up to a 7-mm depth of cut and feature a new cutting geometry. When they are mounted in a cutter body, the inserts’ geometry generates positive radial and axial rake angles, helping to ensure smooth, efficient milling with soft entry into and exit from the material.

These tools can machine 90-degree shoulders up to a 7-mm depth and perform slotting, ramping down, helical interpolation, and facing operations.

The inserts are available in the following configurations:

- H690 WNMU 0705PNR-MM is an insert with six right-hand cutting edges, suitable for milling steel.

- H690 WNMU 0705-PNTR is a general-use insert with six right-hand cutting edges for milling numerous cast iron and steel grades.

- H690 WNMU 0705PNN-MM is an insert with six neutral cutting edges for machining steel.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI