- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

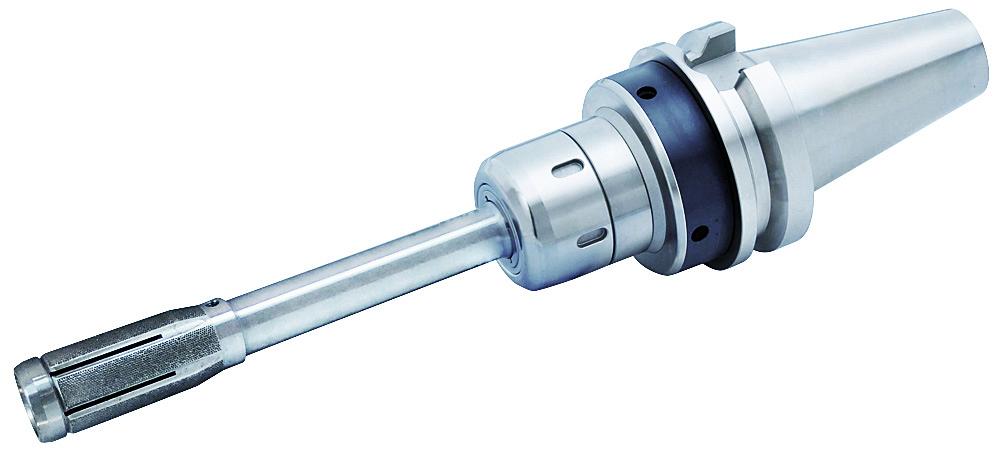

Runout Adjustment System Made for Large-diameter Cutting Tools

- October 6, 2015

- News Release

- Management

NT Tool has introduced the R-Zero runout adjustment system for its CTZ toolholders, designed for use with cutting tools with large diameters.

A four-point adjustment mechanism makes it possible to adjust runout at the tool tip to as low as 0 to 2 µm. These holders are suitable for cutting tool diameters of 1 to 1.5 in.

An electromagnetic, rustproof coating helps to ensure the holder’s accuracy and balance over its lifespan.

These toolholders use the same clamping system as the company’s CTS Super Tite-lock milling chuck, which is designed to prevent slippage and pulling out during heavy machining. In addition to the high gripping force of the mechanism itself, the toolholders have a T-slit inside the bore, giving the compressed cutting tool an area to expand. This locks the tool in place and prevents it from moving either sideways or vertically even under great force, the company reports.

They are available in CAT (standard and two-face contact), BT (standard and two-face contact), HSK, and UTS shank styles.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI