- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Welding Robot Programmability

Getting the most out of your robotic welding system

- By Kevin McWhirter

- January 24, 2012

- Article

- Welding

With the increasing level of competition, it is becoming more and more important, and in many cases critical, to improve productivity. Whether a shop's goal is to meet demand by increasing throughput or to reduce overall production costs, robotic welding systems have been proven time and again to be a means to improve productivity when implemented properly.

The key ways to shorten the ROI and improve the long-term payback efficiency of a robotic system is to shorten the launch cycle and to reduce the time it takes to get each part running successfully in production and to keep that part running as efficiently as possible.

Since robots for welding applications became available in the 1970s, a number of programming enhancements have been achieved.

Conventional Interfaces

The conventional programming interface for a welding robot is a teach pendant—a method still largely used today. In teach pendant programming, the programmer jogs the robot to the desired position using the keys on the teach pendant's jog controls and records each desired position. This is done while the programmer is standing near the robot manipulator.

The displays on older pendants usually had limited functionality, and much of the program editing, such as adding instructions, had to be done at the controller via a large cathode-ray tube (CRT) monitor after the positions were taught.

As the programming functions for robots evolved, the teach pendant displays started to get larger, and the teach pendant itself became a main programming interface.

Many of the programming functions now available on the pendant and CRT displays are no longer a required component of the robotic system.

The teach pendants today are color touchscreen controls that offer easy-to-use interfaces for programming. The interfaces also are customizable for each application to allow more intuitive operation of the system.

Programming languages have evolved over the years, from machine code to a more basic language, which is easier for non-computer programmers to understand.

Most robot brands have their own proprietary language platforms and are able to perform most of the basic functions expected of a welding robot. Some platforms also provide access to lower-level functions, which allows them to be more customizable. The lower-level access allows the programmer to develop complex instructions and data types to perform functions that are not supplied with thestandard robot software. These open-architecture systems give the ability for some to handle very advanced applications.

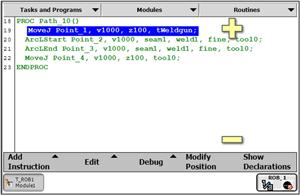

A simple weld routine called Path_10 is programmed with the first position taught as Point_1. It will move using the MoveJ instruction (air-cut move).: The first weld position (arc-start point) is where the position is Point_2 and the weld parameters are defined inside seam1 and weld1. This is known as the seam data and weld data. Each weld can be programmed with the same seam and weld data, or each weld can have totally unique seam and weld data.: The weld is completed, and the remaining welds on the part are simply repeats of the first weld. Often the copy and paste functions can increase the speed of the online teaching method.

Online, or Teach Pendant, Programming

With the online teaching method, the programmer works in close proximity to the robot, positioning equipment, and weldment. The programmer manually jogs the robot to each desired position and then records that position.

The key to this type of programming is for the programmer to understand that he or she is teaching positions in space that are relative to an origin point (referenced from the base of the robot). When each position is taught, the programmer selects the type of move to define how the robot will move to that position.

For example, if the torch has to follow a straight line, the programmer uses the MoveL instruction; if the torch has to follow a circular path, the programmer uses the MoveC instruction; and if the torch does not have to follow a specific path but must move quickly to the next position, the programmer uses a MoveJ instruction.

These are also known as air-cut moves (movements away from the part that position the robot from weld to weld). These moves generally are at high speed.

During welding, the robot system also requires special instruction, such as ArcStartL (move in a straight line from the weld-start position), ArcLEnd (move in a straight line to the weld-end position), ArcL (move in a straight line while welding), and ArcC (move in a circular path while welding). A minimum of two points need to be taught.

In general, the online teaching method is still used today; however, more and more companies that do robotic welding are switching to offline programming and using the teach pendant only for minor touch-ups. The main disadvantage of the online teaching method is that the robot must be taken out of production during the programming phase.

Offline Programming

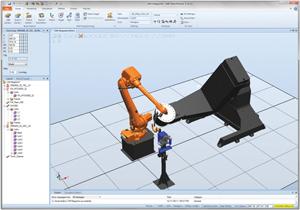

Offline robot programming started to emerge in the 1990s along with the evolution of 3-D CAD and solid-modeling software.

Offline programming

- Ensures proper torch access into the part.

- Determines if reach and torch angles are obtainable before the system hits the shop floor.

- Eliminates costly repairs due to robot crashes during programming.

- Conceptualizes the robot system and establishes process times.

The major benefit of offline programming is that it reduces the time needed to get a new part running in production and the amount of time the robot has to be taken out of production for that phase.

Although typically it is faster to get a part into production with offline programming, a short period of time is required to upload the offline programs, develop parameters, and perhaps perform small touch-ups depending on the precision specified for the application.

The major benefit of offline programming is that it reduces the time needed to get a new part running in production.

Offline Environment

In general, most of the offline programming platforms are easy to use and provide many features to help the programmer teach the robot accurate positions quickly, such as a Snap End Point. Once the Snap control is set to Snap End, selecting the freehand jog to Linear allows the programmer simply to click the mouse and drag the torch to any desired end point.

About the Author

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Class is in session for college connections

BlueForge Alliance partners with Nuts, Bolts & Thingamajigs to develop Submarine Manufacturing Camps

Portable system becomes hot tech in heat treatment

Orbital tube welding webinar to be held April 23

Cidan Machinery Metal Expo 2024 to be held in Georgia May 1-2

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI