- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Pairing Metal-cored Wires with Robotic Welding

Metal-cored wire enhances productivity, quality

- By Tim Hensley

- May 20, 2014

- Article

- Welding

Metal-cored wire is a suitable choice for numerous robotic welding applications, providing productivity increases and quality improvements that can yield a faster ROI.

Robotic welding systems can help manufacturing operations establish and maintain a high volume of production and increase quality, while also reducing costs. Robots provide consistency and accuracy and deliver fast performance, which helps reduce overall cycle times.

These benefits make automated welding an increasingly common option for manufacturing companies.

The ROI of a robotic welding system is an important consideration for companies. Numerous factors affect the ROI, including the choice of filler metal used with the system.

While solid wire has been the industry standard for robotic welding for many years, metal-cored wire is an alternative that can offer significant productivity and quality improvements for many applications, particularly in the manufacture of heavy equipment and automotive exhaust, chassis, and wheels.

Metal-cored Wire Basics

All filler metals have unique characteristics, benefits, limitations, and best applications. Metal-cored wire, on average, has a higher per-pound cost than other filler metals, including solid wire, but it also offers significant benefits as a return on that upfront investment.

Metal-cored wire consists of a metal sheath filled with metallic powders, alloys, and arc stabilizers formulated to create distinct effects, providing higher impact strengths and controlling silicon deposits in the final weld. Metal-cored wire carries higher current densities than solid wire of the same diameter (at equivalent amperage settings), which allows for more weld metal to be placed in a joint in less time. Metal-cored wire excels in many robotic welding applications— including mild, stainless, and low-alloy steel —in large part due to this increase in weld metal deposition rate.

While it offers the greatest benefit in flat and horizontal positions, metal-cored wire can also be used in single or multipass welding in most positions, including vertical-down and overhead welding, using a standard CV (constant-voltage) power source.

It also is suitable for vertical-up welding, though short-circuit transfer or pulsed welding must be employed in those cases.

Productivity and Quality

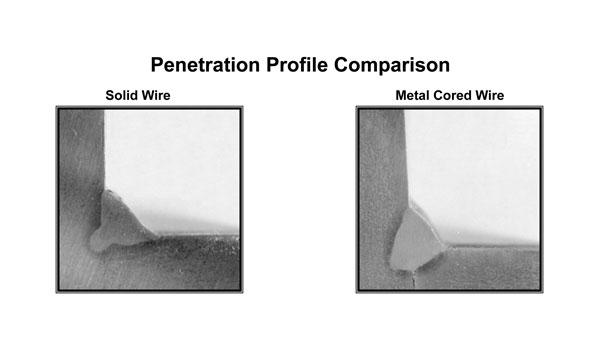

Figure 1:

Metal-cored wire features a broad, cone-shaped arc that results in a wider penetration profile as compared to the more fingerlike penetration of solid wire.

Metal-cored wire is known for several key attributes, including welds with little to no spatter, excellent gap bridging, reduced burn-through, wide penetration profile, fast travel speeds, high deposition rates, and the ability to weld through light rust or mill scale.

These qualities are advantageous in most welding applications, but they are especially beneficial in contributing to the increased throughput sought in robotic welding operations.

For example, companies can increase overall productivity by minimizing non-value-added activities in the pre- and postweld stages, which helps increase workflow and allows for labor resources to be dedicated elsewhere. The ability to spend more time on value-added activities in the welding operation adds to the overall productivity.

So how does metal-cored wire increase productivity and reduce quality problems?

•The broad, cone-shaped arc results in a wider penetration profile as compared to the more fingerlike penetration of solid wire. The coneshaped arc creates a larger, more consistent bead profile that bridges gaps without burn-through (see Figure 1).

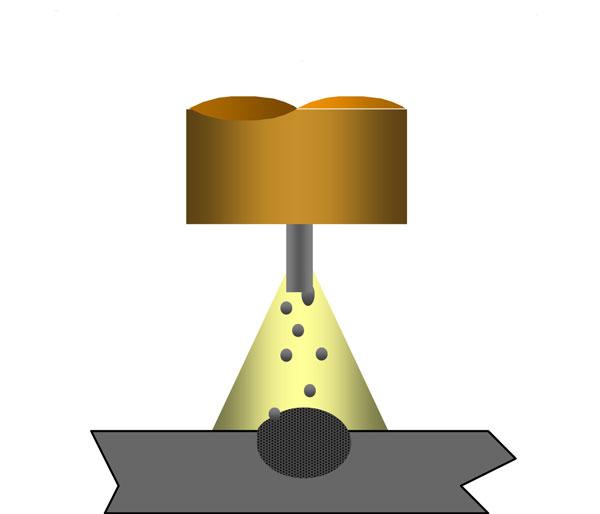

•It uses the spray transfer process, which creates tiny filler metal droplets that deposit in the weld puddle and generate little to no spatter (see Figure 2).

•Higher deposition rates and greater travel speeds—in some cases 20 to 30 percent faster—result from the wire’s construction.

•Stable arc initiation and minimal turbulence in the weld pool help improve deposition efficiency.

These features also help minimize porosity and undercut in the final weld.

Preweld, Weld, and Postweld

Figure 2:

Metal-cored wire uses the spray transfer process, which creates tiny filler metal droplets that deposit in the weld puddle and generate little to no spatter.

In robotic welding operations, some tasks are common to both preweld and postweld areas.

In preweld processes, common tasks include precleaning of the base material, applying antispatter, tacking parts, and moving parts and positioning them in fixtures. During postweld, common activities include removing spatter and slag, grinding welds prior to painting or coating, and moving parts to final production areas.

Using metal-cored wire can eliminate several of these steps in robotic welding applications, improving cycle time.

Preweld Benefits. Some prewelding tasks in a robotic welding operation will always be necessary, such as part tacking or loading parts into fixturing. However, using metal-cored wire makes it possible to reduce or eliminate some other preweld activities that add time to the process.

<>Because filler metal manufacturers formulate metal-cored wire with added alloys, arc stabilizers, and deoxidizers, it can be used to weld through mill scale, reducing the need for grinding and sandblasting. Companies also can reduce preparation time and costs using metal-cored wire because there is no need to apply antispatter compounds before the parts are welded. Antispatter compounds are known to be messy and typically increase the need for cleaning the weld area.Postweld Benefits. Improvements in postweld activities provide some of the greatest opportunities for optimizing robotic welding applications with metal-cored wire. The wire can reduce or eliminate the need for postweld spatter cleanup and repair and rework stations.

Eliminating these time-consuming postweld operations can help companies increase the flow of completed parts to other stages of production, such as painting or coating, which helps improve overall productivity. The ability to focus labor and resources on other areas of the process also helps lower costs and can result in a faster ROI stemming from higher productivity levels.

Maximizing the Technology

Using metal-cored wire in robotic welding applications can provide benefits in other parts of the process besides the preweld and postweld phases.While pairing metal-cored wire with a power source offering pulsing capabilities is the appropriate choice for out-of-position welding, that combination also offers benefits for inposition welding. It provides accurate and fast seam tracking, and the pulsing action can shorten the arc, making the weld puddle more manageable and lowering heat input into the part. Lower heat input helps minimize the risk of burn-through and distortion.

Manufacturers hoping to get the most from metal-cored wire in robotic welding applications should be sure to select the right contact tip and choose the most appropriate wire diameter. The wear on the contact tip in robotic welding is greater than in a semiautomatic welding application, since robots have the ability to weld more parts per hour.

Because of this difference, heavy contact tips and chrome zirconium tips are good choices to withstand the greater amount of welding wire passing through the tip. Reducing the frequency of tip replacement also helps minimize equipment downtime for changeover, so more time can be spent welding.

The diameter of wire being used in many robotic welding applications can also be increased in most cases. For example, increasing from a 0.045- to 0.052-in.-dia. wire, or even up to a 1⁄16-in.-dia. metal-cored wire, allows the robot to put a greater amount of weld metal in the joint.

For optimal results it is best to weld in the middle of the recommended operating range for each specific metal- cored wire. Doing so helps provide the best quality results and allows companies to gain the most out of metal-cored wire’s attributes.

In the end, robotic welding can offer productivity and quality improvements and cost-saving benefits for companies. Pairing a robotic welding system with metal-cored wire can serve to enhance these results in many manufacturing applications and help support an even greater return on investment.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI