- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Cutting High- Taper Angles with Soft Wire

Soft wire outperforms hard wire in high-taper EDM

- By Steve Bond

- February 18, 2015

- Article

- Metalworking

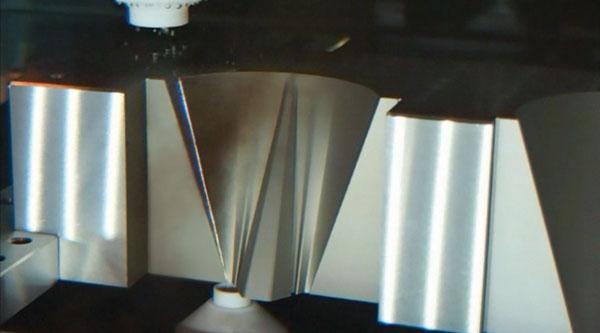

When conventional machining processes cannot successfully cut high-taper angles, wire EDM can get the job done.

But moldmakers using this technology face challenges when cutting taper angles 10 to 45 degrees. While EDMs have the axis movement necessary to achieve the desired angle, the physical properties of the wire in stock may not be adequate. Examining the wire’s properties is useful in choosing the right wire for the best cut.

Soft Wire for High Tapers

The best way to cut high tapers is with soft wire; that is, wire with a tensile strength of ≤ 500 N/mm². Low-tensile- strength soft wire bends easier to follow the path the CNC creates to provide more accurate cuts. However, soft wire has less “memory” than hard wire and is prone to breaking during aggressive cutting. It also is sensitive to the voltages and tension the EDM unit applies during the automatic wire feed (AWF) cutting cycle. If not handled properly, the result is a curved wire, which prevents it from being inserted into the wire guides. In these instances, the machine is unable to thread or rethread the wire, stopping the erosion process and wasting production time.

To overcome the challenges of soft wire threading, manufacturers should use EDM equipment that provides the best wire processing during the AWF cutting cycle. Employed technology should include a way to precisely control wire tension and the energy used to cut the wire.

The ideal AWF situation is one in which the wire heats and stretches until it breaks in two without melting. When the ideal voltage is used to cut the wire and form a bullet point, soft wire threading performance is improved, as is wire straightness, which decreases electrode wear.

It is not just the “hardness” or “softness” of the wire that needs to be considered either. Other factors such as wire diameter, cutting and anneal tension, and voltage need to be finetuned based on the wire selection to preserve the shape of the wire tip, minimize damage to the face, and maximize straightness.

Accurately controlling wire tension also is critical, especially when cutting with soft wire. Using an AWF system that includes a wire tension monitoring device is important. EDM systems that include a dual AC motor and encoder wire drive system working in tandem—enabling the tension motor and drive roller to communicate energy usage to the controller— allow the operator to better maintain wire tension throughout the cutting process.

The operator also can take some measures to improve cutting performance and accuracy when using soft wire. They include the following:

- Use a die guide designed for large-taper cutting, especially if you are going to skim-cut the large tapers to improve surface finish and accuracy. These guides have a much larger support to help the wire transition through the large angles.

- Use the CNC’s features to compensate for the changing position in the Z-axis direction so that the taper angles are precise.

- Reduce wire tension if the cutting technology being used was developed for hard brass wire.

Soft Wire EDM Applications

The many technology developments in the EDM arena have changed the scope of EDM across many industries, including aerospace, medical, and moldmaking. In particular, the ability to accurately and efficiently machine taper cuts using soft wire has opened up new areas of opportunity for the technology.

Medical. This industry regularly requires parts with steep angles. Surgeons depend on the accuracy of these angles to ensure proper placement of components in patients. The more accurate and smoother the finish, the less additional, timeconsuming fitment the surgeon needs to do.

Aerospace. In the aerospace industry, expensive broaches typically are used to machine angled slots in rotors. Now, however, many of these slots can be machined by tapering the wire and accurately holding size.

Moldmaking. Moldmakers in North America are now seeing the return of tight-tolerance mold manufacturing from overseas. EDM can create accurate and fine finishes on hightaper surfaces, allowing extrusion mold builders to design molds with complex shapes. Because extrusions are gaining popularity, there is a constant need to improve strength and reduce weight to save energy. Molds that flow better have several advantages, including reducing electrical costs for the extruders and producing forms which have thinner yet stronger walls.

Why Not Hard Wire?

While hard wire (≥ 900 N/ mm²) is stronger, straighter, and more resistant to breaking and deflecting during cutting than soft wire, harder, hightensile- strength wire also can cause vibration when cutting high tapers as the wire travels between the upper and lower wire guides. In addition, hard wire’s “memory” leads to variation from the programmed wire path, which bends the wire and can lead to reduced accuracy; poor surface finish; and wire breakage, which leaves marks on the workpiece and wastes material and production time.

Note: EDM wire is classified as half-hard wire when the tensile strength is approximately 750 N/mm2.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

- Industry Events

ZEISS Quality Innovation Days 2024

- April 15 - 19, 2024

Tube 2024

- April 15 - 19, 2024

- Düsseldorf, Germany

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada