- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

5 Questions With...

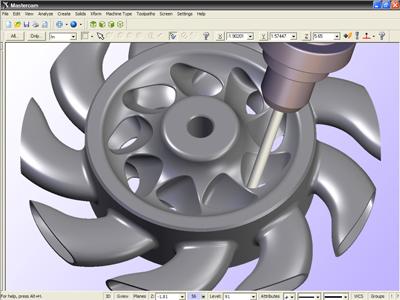

Dave Boucher, Lathe Product Manager, CNC Software

- March 1, 2010

- Article

- Metalworking

Today’s multitasking equipment allows many operations to be carried out at any one time, which can potentially increase productivity, reduce WIP, and reduce the cost of the final part.

However, as the machine’s axis movements and tool paths become more complex, so does programming.

1. What are the challenges with programming multitasking machines?

Challenges include balancing and synchronizing operations between different streams [tools] and spindles to minimize cycle time and avoiding collisions between the many moving pieces of the machine. Other considerations include transferring the part between spindles and programming a full range of mill and turn tool paths in a single program. There are more features and modes on the machines, so the CNC programs are generally more complex.

2. How does this type of programming differ from the conventional style?

Programming for multitasking is not a purely sequential operation. The programmer needs to consider the interaction between different streams and determine how to synchronize these streams to avoid collisions and minimize cycle time. They will also consider which operations are best done with which stream and, in some cases, on which spindle to get the job done in the most efficient way.

3. How important are simulation tools?

Machine simulation is a very important tool for programming multitasking machines. Simulation is used to detect programming errors that may result in expensive collisions. These issues cannot be picked up at the tool path-generation stage because the state of each movable part is not known at this point. This makes simulation of the process necessary.

4. What should programmers look out for at this stage of programming?

Simulation is also used as an aid in applying synchronization [or wait points] to optimize the program for the target machine. However, be aware that accurate simulation is difficult to achieve and is not a catch-all. There is no substitute for caution when proving out the programs for real.

5. How can a programmer utilize the full power of both the turning and milling capability of these machines?

Combined mill and turn capability is a major factor with multitasking machines, especially those with a full B-axis head/tool changer (this usually replaces the upper turret of a traditional lathe configuration). Many of these configurations have full three- to five-axis milling including simultaneous, so strong milling tool paths and capability are an important consideration. It is less of factor with the Swiss-style, sliding-head machines, but some variations of these machines are now offering more milling capability.

For more information, visit www.mastercam.com.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI