- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

New Robotic Safety Standards Can Improve Plant Efficiency

Low efficiency can be avoided, in part, by keeping up-to-date on safety

- March 14, 2014

- Article

- Management

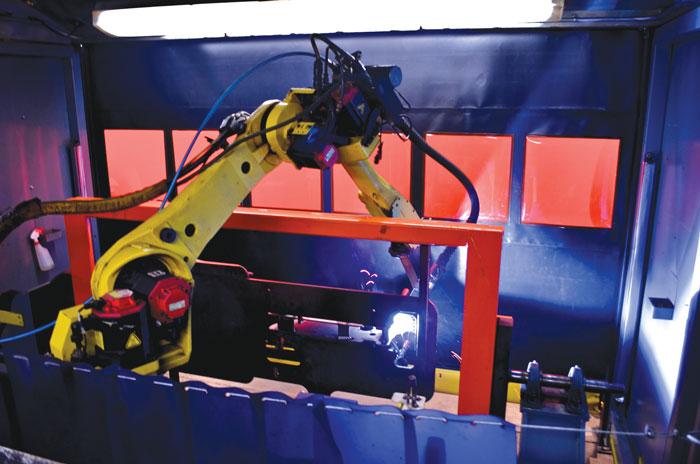

New safety standards include provisions for robotic integration to keep workers safely away from the work zone.

The past two years have been marked by significant changes in industrial safety standards throughout Canada and all of North America. Safety managers and plant managers who were not carefully monitoring these developments might find they are no longer up to code, risking costly fines and morale-sapping injuries to employees.

In today’s technologically complex plants, highly trained employees are more valuable than ever. Therefore, safety-minded managers are quick to follow new standards that reflect the advances in technology at their facilities.

One of the best ways to maintain a safe work environment is to conduct a thorough risk assessment, especially when new automated processes are being implemented. Because of the CAN/CSA Z434 standard that was adopted in 2013, proper risk assessments have become mandatory.

Harmonizing Standards

The new Z434 standard references ISO 10218-1 and -2, which address robots, robot systems, and integration. The new Canadian standard was written alongside the Robotics Industries Association (RIA) in the U.S. to be compliant with international standards already in place in Europe, making life easier for manufacturers and end users.

This standard requires better hazard identification not only for robot motion, but the task being performed. Additionally, it requires validation and verification of the safety systems employed and of the designs that incorporate protective measures for the robot cell and the operator. Because every robot system is different, requiring risk assessments is an important step in protecting employees.

Some of the biggest changes in the new CSA Z434 industrial robot standard have to do with safety-rated motion and allowing for advanced programmable safety devices to be utilized. What this means is software can now take control of the “safetyrated” aspects of the robot’s function, such as limiting the area in which the robot operates and the speed of robot motion. This is a departure from older standards that did not allow programmable safety controls.

Thanks to technological advances in safety controls, these long overdue applications now can be safely implemented. In the past engineers designing these systems guarded for the maximum space, speed, and load of the robot. With these changes, the physical footprint of new robot cells should shrink. Coupled with the proper point-of-interaction safety devices, the smaller footprint may be able to save significant floor space.

Saving Space While Improving Safety

One popular option for point-of-interaction safety devices is automated barrier doors. While the main purpose of these doors is to contain fumes, sparks, smoke, mist, flying debris, excess noise, and other common manufacturing process byproducts, they also can minimize the physical footprint of the robotic cell by eliminating the safety zone that is required by light scanners or light curtains. The most advanced roll-up automated barrier doors offer high speed and high cycles, as well as PLe hold-down mechanisms and safety-rated noncontact interlock switches and controls.

Most automated doors function from the top down, but some have been designed to operate from the ground up. This allows machine operators to easily interact with the process utilizing overhead cranes to load and unload large, heavy parts. They are also an option for interaction points that have a very limited space.

Regulatory Shift

One of the biggest regulatory paradigm shifts in recent memory occurred in 2012 with the move to ISO 13849-1 and EN 62061 from EN 954-1. Support for this change began in 2007, but its opponents were able to put the change on hold in 2009 and kept it there through 2011. While approval of this harmonized standard was a hotly contested fight, it is now here to stay. Fortunately for those in charge of safety, best practices and market-ready equipment already exist.

ISO 13849-1, when broken down to the basics, provides a clearly defined set of rules to follow when designing the safety system applied to industrial machine control systems. Officially defined as Safety of Machinery, Safety- related Parts of Control Systems, General Principles for Design, this regulatory shift was made necessary by increasingly complex manufacturing processes utilizing robotic and automated technology, forcing safety control systems and methodology to keep pace.

The ISO 13849-1 standard is more quantitative than EN 954-1. It applies common sense and forces facility managers to validate their safety systems, whereas EN 954-1 was conceptual and only required facilities to apply safety devices (controls) properly specifying nonprogrammable, out-ofdate technology.

Let’s face it, our increasingly complex manufacturing processes require more complex systems to monitor their operation and keep machine operators safe. Automated processes, robotics, and even time-tested processes all require considerable attention to ensure they can proceed both efficiently and safely. Similarly to CSA Z434, EN ISO 13849-1 will ultimately make for a much safer manufacturing environment because it accounts for the regulatory gaps that were starting to show in the older standards.

New Standards in Safety

Now that these new standards are matching up better with state-of-theart technology, they will help keep workers safe when followed and will actually improve efficiencies in facilities throughout North America.

As new regulations like CSA Z434 are adopted, it is important to stay abreast of the latest safety technologies available to match the right product to the right process, taking not only potential machine hazards into consideration, but also the task being performed.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI