- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Business is Always Looking Up

Vidir Machine’s vertical units use unused space to store almost anything

- By Sue Roberts

- September 12, 2013

- Article

- Made In Canada

Left to right: Peter Dueck and Sid Dueck, co-owners of Vidir Machine; Ernest Rempel, general manager; and Dean Dueck, marketing, stand in front of the new pan carousel vertical storage unit that stores products in an average of 75 percent less space. Built-to-order, the carousels have been purchased to store files, electronics, and small parts in manufacturing facilities.

Vinyl flooring from Home Depot, Menards, and Lowe’s and bikes from Wal-Mart—there’s a good chance those items have spent time in a vertical storage unit built by Vidir Machine Inc., an international company tucked among the fields, off a gravel road just outside the small burg of Arborg, Manitoba. Vidir designs and builds mechanical and automated systems that help companies reclaim and efficiently use lost space. Think about converting unused cubic feet over a loading bay, above an aisle, or in a hard-to-access basement or upper level into accessible storage areas.

Willie Dueck, who still enjoys walking the plant and watching it grow as he approaches his 90th year, established the company in the 1970s. The family-run business began as a small repair shop serving the local agricultural community and producing cattle equipment, grain wagons, and air seeders. Family members also owned and operated a lumberyard that sold vinyl flooring. The need to efficiently deal with the vinyl rolls laid the groundwork for Vidir’s first vertical storage unit.

“We required a way to display and dispense the flooring rolls,” said Willie’s son, Sid Dueck, who leads the company as co-president along with Peter Dueck, his brother-in-law. “The only machine available was a unit out of Germany. Rather than source the machine from overseas we decided to build it in-house. We designed, built, and installed our first vinyl carousel that is still in operation today. Requests started coming in immediately, and we started marketing all over Canada. In a very short time we were installing in the United States.”

Vidir’s carousels and customized offerings quickly became commonplace in retail settings. Carpet, vinyl, tires, clothing, paint, and hardware all found their way into Vidir units. Equipment adaptations for fabrics, print cylinders, small parts, and other storage challenges added companies like Kohl’s, Mercedes-Benz, General Electric, Boeing, and Bell Helicopter to the customer roster. In recent years markets have broadened even more to include venues for hospital bed storage units, consumer self-service propane vending systems, and the VLS (vertical lift system) for heavy sheet metal storage in manufacturing facilities.

“One year ago I had no idea that there was even a need for hospital bed storage,” said Sid. “Today we have a product, a distribution network, and a clearly defined need. This is the nature of our business. I expect that new products and opportunities that we haven’t considered before will continue to become a reality.”

About 100 of Vidir’s 135 employees work in production. Most sales are direct and involve a good amount of interaction between the design engineers and the customers because of the growing number of orders that involve customization.

Two sales offices in the U.S. grow the south-of-the-border business, which is about 85 percent of sales. A warehouse in Pennsylvania avoids custom delays to expedite next-day delivery of parts in the U.S. Customers in South America, Dubai, Saudi Arabia, France, and Australia have expanded the company’s international reach.

Customizing for Tight Spaces

“The style of business we have is changing,” said Dean Dueck, Sid’s son and marketing manager. “It’s shifting from repeat customers and 100-carousel orders to one customer who will order two to five specifically designed units. Small-quantity orders, which probably won’t repeat, comprise about 40 percent of our business. For example, Columbia Pictures called us for a piece of our equipment for a movie set—that one will be a star.”

Large units can be created by linking multiple carousels together using a chain path that ends by bringing items to an easily accessible point. “One customer filled an entire lower level, from floor to ceiling, with storage units. The end of the carousel came up to an icebox-type fixture on the main floor to provide access for stocking and removing product,” said Ernest Rempel, Peter’s son-in-law and general manager. “We’ve also built units in reverse, where access is on the main floor and everything shoots up to the second level for storage.”

Software for the automated units is developed on-site. It is open-source so it can tie into customer systems to manage inventory.

Originally designed with 20 shelves to store and feed sheet metal to Vidir’s flat laser cutters, the VLS (vertical lift system) can be customized to fit a shop’s space and production requirements.

Storage units are installed within their own footprint by Vidir employees. No additional space is required regardless of the unit size.

“We regularly assemble our carousels by craning pieces through an existing mezzanine. In one installation we had only 6 inches of space on each side, but we could accommodate that. This ability to install within the equipment footprint also means that we can get at any of the parts for service or replacement if needed,” said Rempel. “It’s like a puzzle.”

Adding Capacity With New Technology

Engineers at the Arborg location design the pieces that end up in units to solve the storage puzzles. Components that go into these units may be produced in Arborg or Teulon, a second production facility 45 minutes from Arborg that was added in 2006.

Two mills, two lathes, two flat laser cutters, a collection of ironworkers and brakes, and a new tube laser produce parts at the Arborg location before they move through the 1-year-old paint line. The 30-ft. tube laser prompted an 8,000-sq.-ft. addition to Arborg’s 60,000-sq.-ft. facility earlier this year.

The acquisition of new technology is ongoing. “When you drastically change the technology you use to process parts, you find other ways to use the equipment. When we bought our first flat sheet laser we thought we were going to keep it busy three to four hours a day. Three months after its installation, we wrote a purchase order for the second one. Work that was outsourced before was brought in-house, and that reduced our expenses. Parts that were cut on an ironworker or shear were put on the laser for faster and more accurate processing. We expect the same thing to happen with the tube laser,” said Rempel.

The 30,000-sq.-ft. Teulon shop offers similar processes plus automatic rod bending. Two robotic welding stations were added this year. The resulting capacity, quality, and efficiency are bringing production of some outsourced components back in-house.

“We still outsource some simple but labor-intensive parts, but we are finding that as we automate we can compete with offshore costs and produce more of those parts here. That reduces the inventory we need to have on hand and improves our response time when our customers require something different,” said Rempel. “Looking ahead, we will probably add more robotic welding. As we get into larger material that needs short bends, we might add a folding table.”

From In-house Loader to New Product

Up to a month’s supply of raw material is kept in inventory because the somewhat remote location can make deliveries questionable in inclement weather. The flat material inventory led to the development of the first VLS for the company’s own use.

“We were running into an issue with sheet metal storage,” said Rempel. “Since we produced vertical storage, we decided to pull a unit together and customize it to our needs. We designed it to fit with how we unload steel and load sheets onto our laser cutters and produced it at a lower cost than other options on the market.

“Now we are offering it to other companies. We can customize the VLS to specific operations. At Vidir we have a 20-shelf unit with each drawer handling 5,000 lbs., but that doesn’t mean that’s where the capacities have to stop. The number of shelves can be based on space under the ceiling. Unit length can be changed, and we can customize a VLS to handle barstock. We’ve had customers for which a carousel wasn’t the right solution look at this piece of equipment and want to drive away with it.

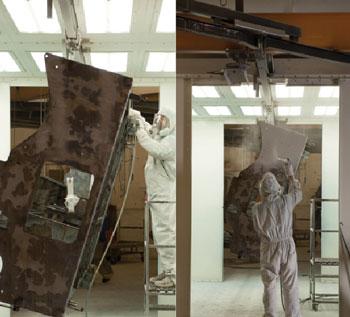

Overhead rails move parts from assembly through the recently installed paint line, eliminating the finishing bottleneck.

“One of our biggest strengths is that we can design a product, produce the parts, and put it together fast. We can react very quickly to a customer who has a unique challenge. With the engineers here we assemble and test a product before it is delivered.”

At any time Vidir has three or four new projects in the works. How long it takes to go from concept to product depends on the volume of business. Rempel said, “When a customer calls, we do their project first. Then we go back to our own wish list.”

Photos by Walter Janzen, Janzen Photography, unless otherwise noted.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI