- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Over-sized Precision Is the Standard Order at Concorde Precision Machining

Unique Equipment and Expert Operators Machine Massive Parts

- By Sue Roberts

- November 18, 2013

- Article

- Made In Canada

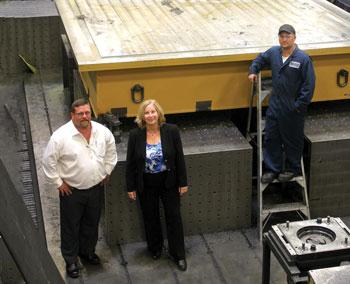

Concorde Precision Machining Inc., Lakeshore, Ont., specializes in machining large components. Left to right: Peter Gobel, general manager; Diane Reko, CEO; and Jamie Buhler, machinist, look up from the floor of the Medve 3, one of the large vertical machining centers designed by former CEO Steve Reko.

Bears and bulls. Not what you’d expect on a machine shop floor. But at Concorde Precision Machining Inc. in Lakeshore, Ont., large, precision machining equipment carries Hungarian monikers culled from the animal world. The Reko vertical gantry machining centers are known as Medves, or bears; the horizontal machining centers are the Bikas, or bulls.

The Medves and Bikas are monsters. The largest vertical center has a work envelope of 450 by 184 by 120 in. The largest horizontal center machines parts up to 526 by 120 by 120 in. Peter Gobel, general manager, said the heaviest piece machined to date weighed just over 100 tons.

Concorde’s 90,000-sq.-ft. shop is one of the few places that these tools call home. Their unique names, along with their ability to machine large parts to tight tolerances, were the concept of Steve Reko, a machinist who emigrated from Hungary and whose Canadian career evolved into moldmaker. Molds eventually became the core business of Reko International.

Steve remained a machinist at heart. In 1994 he grabbed an opportunity to buy in to Concorde, then a small machine shop. The Concorde name was kept in place as a nod to the shop founder, Paul Jacquart, who at a previous employer provided machined parts for the Concorde jet.

Diane Reko, Steve’s daughter, has taken the helm of Reko International Group Inc. since his passing in 2007. She steers Concorde and the group’s three divisions that carry the family name: Reko Manufacturing Group, Reko International Sales, and Reko Global Services.

“My father had a passion for machines. He was inspired by big, precision equipment. In the 1980s and 1990s he felt that there wasn’t anything on the market that could hold tolerances appropriately, so he designed his own machine to offer more stability,” said Diane. “Before he was done there were four different machine tool designs, and two are still at the heart of our production today.”

The bulls and bears have been busy.

Passionate About Manufacturing

“When we purchased Concorde there were about 10 employees, including the founder and his wife,” said Diane. “We acquired 75 percent of the company and immediately started to expand. We added on to the building, hired more employees, and brought in Reko equipment.”

During the nearly 20 years as a Reko company, Concorde has become a wholly owned division of Reko International Group, gained floor space three times, and gone from producing one-off pieces for a limited number of companies to providing large machined components one at a time or in low-volume lots for multiple customers in the oil and gas, energy, transportation, and machine tool industries. Concorde now employs 50 people, more than a quarter of Reko International’s total headcount.

Keeping It Level

Tolerances of 20 microns over 200 in. are achieved by combining the precision equipment with techniques developed in-house and experienced operators. “There isn’t a machine tool in the world of this size that can hold those tolerances on its own,” said Gobel. “Our operators know their machines, they know the margins of error, and they know how to correct to get the required GD&T [geometric dimensioning and tolerancing] of the finished product.

Eighty percent of components pass through the room-size CMM for measurement verification by experienced operators like Barry Beaudoin, pictured here. The remaining work is laser-inspected within the plant.

“The machines continuously work to these tight tolerances. They have proven that we can provide reliability for our customers’ critical parts. Combined with the quality of people we have here—we have experts, not just tradesmen—we can offer that precision.”

Equipment from other manufacturers also populates the floor. Floor and rotary table boring mills and a room-sized CMM with travel of 200 by 100 by 72 in. keep up with the large-scale Reko equipment. Eighty percent of the jobs flow through the CMM. Electronic precision levels and laser inspection equipment provide flat and vertical measurements for the other 20 percent.

In 2012 a TOS horizontal 4-axis boring mill with travel up to 196.85 by 118.11 by 68.61 in. joined the equipment list. Concorde is currently using floor space to add a vertical turning lathe to further expand capabilities. “We don’t have much room in the plant now,” said Diane, “but we own property behind the building so we can expand again. I hope we’ll have reason to do so in the next couple of years.”

An Eye on Efficiency

The company also offers welding and assembly, typically called on when a final piece is too large to be machined even on an oversized Reko bull or bear. “One job came to us in six sections. We machined the individual pieces, bolted them together, and performed a final machining on the top and side surfaces to make them flat,” Gobel said. “Sometimes it’s just more efficient to break a job down into different pieces. We worked closely with our customer’s design engineers to come up with a manufacturing solution. This is one of the ways we build partnerships with our customers.”

Concorde works with its customers to provide critical parts at the lowest cost of ownership. Incoming material provided by customers is transformed into crankcase components for locomotives and stationary power generation; machine tool bases, slides, columns, and bridges; compressor frames and cylinders; cross rails; and atomic energy assemblies. The company has controlled goods certification for Canada.

“One-offs are still part of our business,” said Gobel, “but there may be many similar parts ordered by one company.” He cited railway engines as an example: “The engines are various shapes and sizes. Each style is a little different, but there is a continuous run on these parts. We don’t see this as production work because the parts are complex and require a high level of expertise from our operators.” Depending on the complexity, the shop may complete four in a week or four to five in a day.

“It’s interesting to see the various applications,” said Diane. “Precision is critical in so many areas. If you think about an engine for generating power for a remote village in Chile, everything has to be perfect. There isn’t a maintenance crew that can jump in and fix a problem at a moment’s notice.”

Customers aren’t just customers; they’re partners. “We’re not just a supplier,” said Gobel. “With most of our customers there is a very close relationship between our quality and engineering departments.”

That works to create products with the stringent specifications in the most efficient manner and helps with scheduling conflicts in busy times. With a little adjustment on both sides, production needs can be satisfied. The top 10 customers have been with the company for more than 10 years.

“Scheduling flexibility is also a large part of our success,” Gobel said. “If one customer puts a hold on a component because of an engineering change in the middle of production, we’ll finish it to a certain stage, remove it from the machine, and hold it until the change has been verified. Meantime, we’ll work on another job. It’s no big deal. It’s the value of building partnerships.”

Machinist Tom Denomme pays attention to a large cylinder casting for the oil and gas industry being processed on Concorde’s new TOS boring mill.

Recruiting: Local and Global

Like many manufacturers, Concorde has problems finding qualified people even though their search has gone global. “Good machinists are rare,” Diane said. “We’ve tried recruiting in South Africa, England, Germany, Eastern Europe … but it’s challenging.”

So they started their own apprenticeship program about four years ago. The first graduates are just completing their first year of work following program completion.

“We’ve had a lot of success,” said Gobel. “We are picky about whom we choose. We look at attitude and see if their makeup fits with Concorde. Are they on time? Are they conscientious? Do they care about their work performance? We don’t initially hire them as apprentices. We might hire them as a general laborer and see if they fit.

“Once they are here, we keep them challenged and pay them for their knowledge. I have a lot of bright guys who have engineering capabilities, good deductive reasoning, and the ability to think on their feet. They make hundreds of decisions regarding their job every day. We expect a lot but a skilled operator at Concorde lives very comfortably. We have a very low employee turnover rate.”

It’s not all work and no play. Corporate traditions gather employees from all divisions for barbecues, golf tournaments, summer family picnics, and an annual formal Christmas dinner. Each month an employee is featured in the company newsletter, “The Metalcutter,” to familiarize others with his or her face and job responsibilities.

“Even though we are a midsized company in terms of headcount,” said Diane, “we put forth a concerted effort to make it easy for people to interact and get to know each other. That helps strengthen our team.”

Diane’s vision for the future: more expansion, additional vertical turning capabilities and capacity, and increased recognition as a precision machine shop on a worldwide basis. The company is on its way.

“We recently quoted a large project for a European company. Five companies were invited to quote—four companies from Germany and us,” said Gobel. “It’s great to know that our quality and reliability are getting global recognition.”

Photos, unless otherwise noted, by James Gervais.

Manufacturing Day 2013

Reko International Group was one of six inaugural Windsor and Essex County companies to open their doors to educators and students as part of Manufacturing Day in October. The North American event—supported by the Fabricators & Manufacturers Association International; the National Association of Manufacturers; the Manufacturing Extension Partnership; the Manufacturing Institute; Industrial Strength Manufacturing; and the Science Channel—was initiated to give students a first-hand opportunity to discover what manufacturing is today and the career opportunities it offers.

“We were able to show our machining, moldmaking, and automation facilities to about 50 high school students and their teachers,” said Diane Reko, CEO of Reko International Group, Lakeshore, Ont. “Hopefully, events like these will get students thinking about the possibility of a career in manufacturing. They can design, machine, and build exciting things and earn a good income while they are doing it. We as manufacturers need them to understand that.

“The days of old-school tool-and-die shops are gone, and I think many of the students were surprised by the level of computerization in today’s plants.”

Following the two-hour tours hosted by company managers, comments included, “I could see myself working here” and “It’s great to see youth taking an interest in our industry.”

Visit www.mfgday.com for more information on the initiative and to learn how to become involved in the October 3, 2014, event.

Photos courtesy of Reko International Group.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

- Industry Events

ZEISS Quality Innovation Days 2024

- April 15 - 19, 2024

Tube 2024

- April 15 - 19, 2024

- Düsseldorf, Germany

Lincoln Electric's Large Format 3D Metal Printing Seminar

- April 16 - 17, 2024

- Cleveland, OH

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada