- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Excavating Mining Profits

Carriere Industrial Supply builds equipment that wears well

- By Sue Roberts

- August 5, 2014

- Article

- Made In Canada

Jean-Marc Valade (left), president, and Pierre Levesque, IT manager, of Carriere Industrial Supply, Lively, Ont., stand by the recently commissioned 118- ft.-long Messer combination table with a 12-ft.-wide cutting bed.

Grab a torch. Cut the new bucket into cage-sized sections. Transport them underground, piece by piece. Weld them back together. Take good care of that bucket. Its size will likely keep it captive in its work area. Getting it above ground for refurbishing will require reversing those costly steps.

Moving equipment into place and maintaining underground air quality are significant expenses for mining companies. Cage dimensions present a challenge, and hauling equipment to subterranean locations can postpone ore extraction. Welding those components together again in a mine shaft’s confined space creates air quality issues.

Carriere Industrial Supply Ltd. (CIS), Lively, Ont., understands the muck circuit and what needs to be done to lower costs and keep mines working profitably. Customized mechanical LHD (load, haul, dump) buckets that are modularly assembled on-site and wear liners to protect the material handling infrastructure comprise the company’s main underground product lines.

“Buckets have gotten larger over the years to extract more ore,” said Jean- Marc Valade, president, who joined CIS in 1996, “but the shafts and cages that go underground are of a fixed size. So we pioneered a mechanical bucket system that is easily transported underground and basically eliminates the need to cut a bucket apart and reweld once it is in place.

“A bucket that would have taken a week or two to put in place now takes only a shift. And by strategically placing the wear material on these mechanical components, we also addressed the wear points so the buckets last longer.”

Mining New Markets

CIS primarily serves the mining industry, but plans are in place to diversify. The 2014 addition of a Messer TMC4500 DB with integrated plasma and oxyfuel cutting, beveling, and drilling plus the latest expansion of the welding facility have increased productivity so there is capacity for new product lines.

Growth is a company trend dating back to Armand Carriere’s 1960 founding of Cobalt, Ont.-based AMC Supply as a distributor of mining wear products. A decade later Mike Carriere, Armand’s son, and AMC Sales Manager Mark Andrews, now retired, applied their experience in mining operations and maintenance to expand the distribution lines. They also changed the company name.

During the late 1980s and early 1990s, focus shifted from distribution to manufacturing and the Lively production facility opened. A 6,000-sq.- ft. expansion was added in 1996 to house a warehouse, paint booth, and expanded welding operations. In 2004 a 5,000-sq.-ft. state-of-the-art welding shop was added along with a 50-ton auxiliary overhead crane to handle the increasing weight and size of the fabrications.

Last year’s growth included another 10,500-sq.-ft. building, a 12,000-sq.- ft. automated yard crane for moving raw materials, and two new Messer cutting tables to replace the singlegantry cutting machine and manual drill presses.

The long-reach robot applies multipass welds on a fabricated lip assembly to support a mobile bucket. The operator mounts the next bucket component for robotic welding.

Positioned on 7 acres of land with buildings that house 30,000 sq. ft. dedicated to production, the company is ready to grow again. “It looks like we will be expanding the large fabrication facility by the second quarter of 2015,” Valade said. “We are also considering building additional office space to consolidate all of our office requirements into one site.”

Away from home base, CIS recently opened an office in Saskatoon, Sask., to service the potash, coal, and uranium mines of western Canada and entered a licensing agreement with Keech Castings in Australia to manufacture its line of LHD buckets.

Building in Savings

Each of the 300 product SKUs that pass through production each week is tagged as a large or small fabrication depending on the number of hours involved from design to completion. Items like lip assemblies and heel assemblies for bucket components take less than 40 hours to finish and fall in the small category. Products like the buckets that may require 100 or more hours each are in the large category. Girth of the product is typically in proportion to volume of production hours.

CIS products save time and money. Pierre Levesque, IT manager, said, “Our products are strategically sized and mounted on special dollies or skids to facilitate logistics and reduce cage time for bringing them to operations areas.

“The mechanical assemblies eliminate toxic fumes from underground welding. They also let us provide replacement components for high-wear areas that can be installed without removing the bucket from the machine.

“Most changeouts can be performed in a single shift. With this strategy, a bucket in the field stays attached on the machine three times longer before it needs to leave the mine for refurbishing.”

Welding In-shop and On-site

Even with special attention to design, some pieces are just too large to transport as single units. Immense equipment that needs to travel in manageable sections prompted the creation of the rapidly growing field service department.

“Sometimes a new assembly will have to be cut up or designed in separate pieces to accommodate transportation then welded back together on-site. Our mobile crew may be the same welders who worked on the project in the shop, but we’re looking to add 15 to 20 more welders specifically for work at remote sites,” said Levesque.

“On the refurbishing side, our customers often prefer to do the work themselves but have trouble finding experienced, skilled people. We provide the expertise to maintain the equipment, and that also gives us control over the rebuilds,” he added.

Assuring quality rebuilds has a direct correlation to CIS profits. Customer contracts are similar to leases, with payments based on tons extracted. CIS owns and maintains the equipment and is responsible for making design changes to improve performance. The cost-per-ton system works well for the mining companies and keeps CIS looking for ways to improve equipment productivity.

Valade said, “We are constantly balancing the wear goals of the client along with maintaining the ideal bucket weight for operations to ensure maximum payload. Reduction in bucket weight equates to more ore being hauled.”

Managing Customization

Mining equipment is not one-size-fits all. Mining circuits have hundreds of different types of equipment, unique to each application. Wear liners vary in size and configuration, specific to each piece of equipment that needs cladding. New equipment is custom designed with considerations made regarding the material being mined, material impact, abrasion, weight, and access for routine inspections.

“We have over 20,000 different liner pieces for multiple customers, so we developed our own software that is fully integrated with our cost and production system,” said Valade. “We supply this information digitally to customers so it can be integrated into their own enterprise systems.”

Linerwear is a large-scale database that houses technical information about individual liners, provides CAD drawings detailing each product, and hosts cost reports along with predictive wear patterns. The in-house software, written by Levesque, pairs with the accounting system to price the custom parts. It helps centralize purchasing needs and reduces the customer’s cycle time from order to delivery.

Bucketwear, another software system developed in-house, similarly maps the mobile equipment circuit per mine site. It allows the operation of a mobile bucket fleet to run under a cost-per-ton model and generates monthly tonnage billings to cover the costs of managing the buckets in the field.

“The first piece of software I wrote was to bridge the gap between the nesting software and the accounting system that dispenses pounds of steel. That was in 1997,” said Levesque. “Since then we’ve evolved and added the capability to accurately quote steel prices. These capabilities have all been developed to work hand-inhand with our production software.”

Growing Capacities

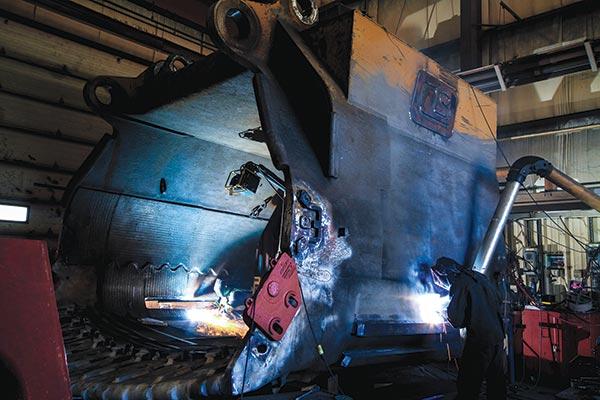

Welders apply a new wear package to the inside and outside of a large shovel dipper during a heavy-rebuild process.

Workforce expansion is keeping pace with space and equipment investments. Since January 2014 employee count has grown by 25 percent to 130. The shop generally runs two nine-hour shifts five days a week. Exceptions are the cutting and drilling operations and the robotic welding cell, which run 24 hours a day during the five days.

The size and complexity of many of the pieces demand manual welding. But some higher-volume, replaceable components for the mechanical buckets pass through the 4-year-old robotic weld cell.

“The robotic cell is quite sophisticated. It has the ability to preheat material and apply welds using various nozzle sizes selected from a tool carousel. It uses touch-sensing and seam-tracking technology,” said Levesque. “When it came to our welded lips, we invested in an elaborate program that self-calculates assembly geometry to reduce setup and programming time.”

Materials are tough, generally quench-tempered plate with a hardness up to 52 on the Rockwell C scale. Full plates, up to 6 in. thick, present challenges for material handling, drilling, and cutting.

Automatic material carts move steel along rails stretching from outside storage, through the building, to butt the material up against the appropriate cutting table. Plates are transported in the position they will go on the bed. The carts are interconnected with machine logic that monitors where they are on the rail and moves them to the machine when there is a production opening. The automation protects the equipment and the employees.

Partnering With Suppliers

Working with heavy, hard materials is tough on equipment and tooling. Working with suppliers augments the company’s abilities to improve tooling and equipment performance and longevity.

Drilling and cutting challenges were addressed by working with Messer to customize the largest plate processing machine available from the company. Design changes were made to accommodate the heavy duty cycles.

“Drilling on this type of machine is still pretty new to the industry. We ask for things that make sense and we develop the capabilities together,” Levesque said. “For example, we’ve been able to pass variable information to reduce drill cycle time for complex, three-tool holes, which was not an original feature. It reduces our time significantly.”

The dual-gantry machine is outfitted with Hypertherm’s high-definition plasma system that can cut plates up to 2 in. thick; the oxyfuel process cuts plate up to 6 in. thick. Movement between processes and parts is up to 1,000 IPM.

“A challenge we face with small orders is processing from the same sheet of steel a number of times before it is completely consumed,” said Levesque. “The ProNest software algorithms prioritize sheet locations and last used information along with customized parameters to help us process those orders efficiently.”

A 24-station automated tool changer holds drills designed from coordinated efforts with Komet for the best feeds, speeds, and carbide selection for drilling 52 HRC plate. “The custom tools last longer and complete the machining tasks in much quicker cycles,” Levesque said. “Initially our countersunk hole time was eight or nine minutes. Now it’s down to three or four.”

Easing Operations

“By designing our cutting facility with two gantry machines, we machine a plate, stop processing, and resume the cutting task on either machine,” Levesque said. “Let’s say we’re processing a full plate. We can drill the whole plate without cutting it. We might take the plate off the table to preheat before cutting and releasing the parts. Then we can put it on either of our tables for cutting—the one with the drill or, if we have more drilling to do, the table without drilling capabilities. Accuracies are maintained either way.”

Ease of operation joins increased production as an advantage to CIS’s sophisticated equipment. “After working closely with suppliers to achieve the equipment capabilities we wanted and defining key process parameters, we have cutting operators who do not have machinist backgrounds producing quality parts,” said Levesque.

Looking forward, Valade said, “Most of our business today is tied to long-standing, mutually beneficial contracts with mining companies. As we expand, we’ll approach our new markets with the same philosophy that has kept us growing consistently at 10 percent per year since 2010: We’re not merely interested in our client’s order, we’re interested in serving his business.”

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI