- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Structural Steel: The Chase for Synchronicity

Technology is replacing manual processing for beams and structural components

- By Asier Ortiz

- April 20, 2015

- Article

- Automation and Software

The structural steel sector is viewed as an industry that processes tons of material using industrial processes with very little automation. The belief seems to be that the tasks themselves do not require automation to correctly produce the parts.

Cutting a bevel on a beam at a defined length, drilling holes, adding a notch to support a joint, and preparing the structural component for welding are not always viewed as high-precision jobs that would benefit from a specialized NC machine tool or an automated machining process.

In fact, in many countries today, it is possible to launch a highly complex structural steel project solely using manual processes and an extensive workforce. In areas where labor is cheap, component features might be handcrafted to meet construction needs without creating a single problem.

This manual-processing scenario can work, but it has a direct impact on project costs. Executing a structural steel project of any kind or size consumes a large amount of resources, both in material and time, which need to be financed. These costs add up quickly and have a direct and negative impact on profitability.

Lately, however, options available to the structural steel segment have changed the work flow. Project lead times are being shortened. Fieldwork is being reduced by preassembling modules fabricated at the factory and transported to the work site. Architectural designs are demanding elegant and exquisite steel components that add to the need for precision and, even more, for beauty.

From Vision to Structure

Implementation of a project begins with the definition of an architectural vision. An effective plan needs to be devised, executed, and managed to efficiently bring the vision to reality, often within a short time frame, while maintaining a profit margin. A move from using spreadsheets and circular saw processes to NC equipment paired with software developed specifically for construction components can allow a spectacular vision to take shape on time and within financial goals.

For a reasonable investment in today’s equipment and software, structural steel companies can reduce costs and, consequently, increase profitability. Technology can allow for the management of more projects using the same financial resources, lower operational costs, automate processes, and optimize each phase of each project. It can help structural steel companies achieve the needed synchronicity in all processes to overcome the challenges faced today.

Structural steel software can allow seamless control of a project from quotation, CAD, production and staging of the components to assembly within the structure. A turnkey program can integrate several key functionalities: design, production, and management of the right elements at the right time. It should optimize production equipment usage, taking into consideration maintenance stops, resource availability, and raw material inflow.

Structural steel automation requires:

- BIM (building information modeling) software to design, define, and identify all parts to be produced and how they should be assembled.

- CAD software to visualize parts in 2-D and 3-D, refine as needed, and mark them to indicate how they should be produced and assembled.

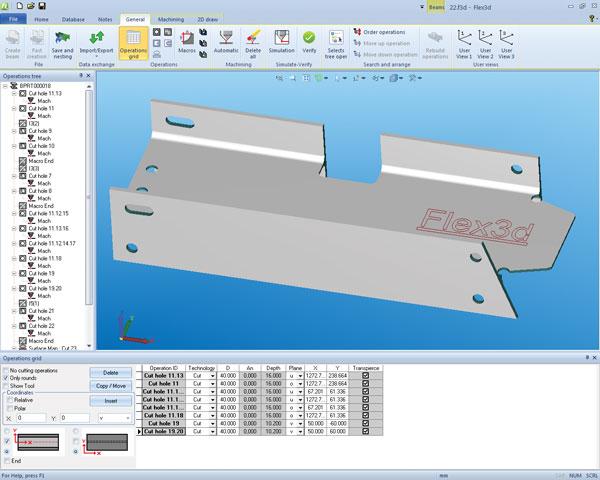

- CAM software to generate machining instructions for every process to avoid head collisions and undesired behaviors while optimizing material usage.

- MES (manufacturing execution systems) software to adjust the production sequence that sets the component delivery flow to the erection site in line with the assembly pace.

- CNC machines to produce part shapes and sizes (I, U, L, H, T, and square or round tubes) at a regular pace with combined technologies like drill, tap, C-sink, ream, and milling with one or several drilling heads.

Add Efficiencies

Steel construction software can provide several advantages to increase overall project efficiency.

It can identify large parts with the same shape but different drills or notches that can be grouped together for efficient fabricating. With the number of parts involved in a project’s construction, it is close to impossible to make such an identification manually.

Effective software can quickly provide the proper information about each part: how it should be produced and when; if and how it should be added to a multipart assembly and when; and when it should be shipped for just-in-time arrival at the construction site.

Structural steel software can allow the fabricator to choose the right part to hoist by a crane and assemble in a joint where several parts converge. Selecting the wrong part can be expensive and time-consuming. The incorrect part has to be returned to the staging area while the correct part is identified and crane time is again used to put it in place. With the software’s marking capability, each part can be marked to identify where it should go and assist with assembly directions by indicating whether connection is by welds, rivets, or fasteners.

The most efficient logistics and transportation options can be reviewed and considered within the software to determine if assembly should be done in the factory or at the erection site. The software can provide inventory management of completed components, indicating when they will be needed, providing the weight of the items so adequate transportation can be planned, and allowing confirmation of installation.

Sheet, beam, and consumable specifications and other purchasing requirements can be generated from the structure design by using the software. Traceability and quality control upon receipt of materials also can be managed within the program.

The steel construction software integrates with BIM software that is responsible for designing and defining the steel structure to share part and assembly information, simultaneously record changes, and visualize progress.

Profit From Automation

The efficiencies gained with software capabilities can justify the investment in automated equipment to synchronize with supply chain processes.

Adding structural steel software for machining and fabricating structural parts to a shop can synchronize design, manufacturing, assembling, and erection processes and increase part quality and profitability.

The structural steel sector has the opportunity and the challenge to go from high-tonnage, handcrafted projects to agile, automated production by taking advantage of newly available IT tools. Are you ready for synchronicity?

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI